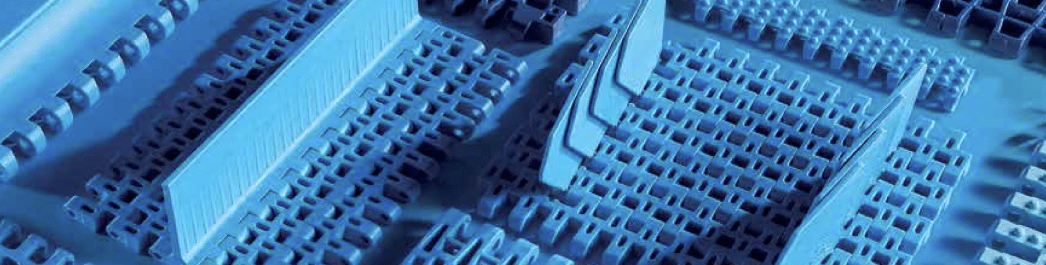

When it comes to impactful conveying solutions for the food industry, resilience is the most crucial element. With the corrosive environments, sterilization requirements, and continual maintenance facing food processing and packaging applications, plastic modular belting provides a holistic solution that can combat each of these challenges head-on.

In this article, we’ll walk you through the key advantages of modular plastic belting and how it can improve the durability and efficiency of your operation. Understanding these features will provide valuable insights into the broader advantages of incorporating this type of belting into your processes.

4 Benefits of a Modular Plastic Belt Conveyor System

Incorporating these systems into your food and beverage processes is a smart way to ensure the productivity and cleanliness of your equipment and product. Not only do they keep food items hazard-free, but their reliability is key to protecting your equipment from wearing down, saving you a considerable amount of money in the long run.

1. Keeps Corrosion at Bay

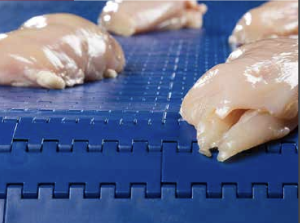

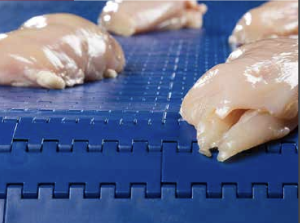

Hygiene in food processing and packaging applications is of the utmost importance. That’s why it’s essential that each operation’s conveying system can help limit bacteria retention. To keep up with the cleanliness standards from the FDA, the food industry benefits the most from a plastic modular belt, as it is easy to clean and provides a low-maintenance solution.

Designed specifically for the food industry, Modutech® plastic modular belting from Beltservice Corporation offers a hygienic design that reduces common cleaning issues in corrosive environments. These belts are molded to the highest standards using the highest-quality raw materials, which comply with FDA and EU regulations and are capable of handling the most stringent sterilization requirements.

2. Increases Your Operation’s Overall Strength

In addition to hygienic maintenance and sterilization, other common challenges in the food industry include pulsation, load capacity, changes in temperature, and impact resistance. That’s where stronger, thicker belting material and sprocket engagement come into play.

With plastic modular belting, you’ll have the peace of mind of knowing that your equipment can handle more load without breaking. This will increase the strength of your food and beverage operation, improving productivity.

Leveraging enhanced belt strength and precise sprocket engagement, Modutech plastic modular belting from Beltservice Corporation slashes unscheduled downtime to keep your system moving perfectly within motion. This belt and sprocket design ensures superior load transmission and belt pull capacity to ensure your operation is achieving peak performance.

3. Decreases Unscheduled Downtime & Optimizes Your Conveying System

Plastic modular belting is more flexible and efficient than traditional conveyor belting due to the nature of its material and functionality. These conveyor belt protection devices allow for customizations with a variety of flights, side guards, and accessories to meet the unique needs of processing and packaging applications, including:

- Fruit and vegetable applications

- Meat, poultry, and seafood applications

- Bakery and pasta applications

- Beverage applications

- Can applications

Featuring plastic modular belting solutions for light, medium, and heavy load capacities, Modutech products from Beltservice Corporation offer uncompromising durability and resilience for food processing and packaging applications.

With high temperature and wear resistance, unique sprocket engagement and locking system, optimal drainage and airflow, and hygienic design, Modutech decreases unexpected failures, breaks, and overall maintenance upkeep for your conveying system, ensuring that you have food-safe conveyor belts.

4. Minimizes Stress of Repairs If Damage Occurs

Thanks to their interlocking design and modular construction, fixing and replacing a damaged plastic modular belt is pretty straightforward. If a problem arises, instead of dismantling the entire system, you can quickly replace the affected area, saving you time and money.

This simplicity in repair ensures that your operation can swiftly address issues, keeping the production process running smoothly. The user-friendly nature of plastic modular belts not only contributes to operational efficiency but also makes them a practical choice for businesses seeking a cost-effective and easily maintainable solution.

Get the Highest-Quality Modular Belting Solutions from Beltservice Corporation

As a world-leading fabricator of custom plastic modular belt conveyors, Beltservice Corporation offers a complete line of modular belts, chains, and conveyor belt components that meet some of the most stringent requirements of food processing and packaging.

This line of conveyor belt components ensures superior product quality and performance, and is available in standard materials like PP, PE, and POM (acetal), as well as special materials such as detectable, antistatic, flame retardant, extra high temperature, hot water-resistant, reinforced and low friction.

If your company handles the production and packaging of food or food-related products, these devices will be highly beneficial to your food conveyor belting system. Browse Beltservice’s inventory to locate components that meet your needs.

Turn to the Experts at IBT for Your Conveying Solutions

To help you reduce unexpected breakdowns and product replacements, our team of conveying systems engineering experts understands the importance of finding and selecting just the right parts for your food industry application.

We’re dedicated to providing you with a custom solution that will ensure maximum performance and efficiency for your food industry conveyor belt. If you’re ready to optimize the performance of your operation, reach out to our team today for a consultation or to request a quote.

If you’re looking for a specific conveyor belt component and would like to purchase your solution directly, visit ShopIBT to access the conveying products we have available online.