Wondering what the difference between “electric motor quality” bearings and standard ABEC-1 bearings are? In this piece, we’ll walk you through the terminology, how electric motor bearings are engineered, what applications to use them in, and how long their life span is.

The term “electric motor quality”, or EMQ, refers to bearings that meet a higher level of caliber and have a reputation for exceeding the performance of standard ABEC-1 bearings. This higher standard ensures electric motors can not only run smoother and more quietly, but also take on a higher load capacity and provide a longer-lasting life.

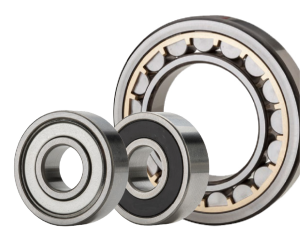

Some electric motor bearings that can fulfill these standards, include ball bearings, cylindrical roller bearings, tapered bearings, and spherical roller bearings. It’s important to note; however, that in order to perform at the optimal level, these bearings need to be properly lubricated according to electric motor requirements. Electric motor bearings from NTN® are specifically engineered for the demanding needs of electric motor applications offering shields, non-contact seals, or contact seals, electric motor grease, and C3 clearance.

Which Applications Use Electric Motor Bearings?

Electric motor quality bearings are designed specifically to handle applications that are high-speed, high-stress, and require optimal precision. Unlike standard bearings, electric motor bearings can uphold quality and avoid causing unwanted damage to a system, even at the highest speeds and strains. Some of the applications that would benefit best from electric motor bearings include:

- Alternators

- Blowers

- Compressors

- Fans

- Machine Tools

- Power Tools

- Pumps

- Rolling Mills

- Turbines

With electrical currents passing through electric motors, it can expose standard steel bearings to electrical bearing damage. This can result in uneven surface texture in the inner and outer ring raceways, which can cause vibration issues and could lead to overall failure of the bearing. That’s why NTN offers their MEGAOHM™ Series and hybrid bearings that feature ceramic rolling elements. NTN’s MEGAOHM™ Series has an insulated coating on the outer ring to prevent electrical current from going through the bearing. These are available in deep groove ball bearings and cylindrical roller bearings. NTN’s hybrid ceramic EMQ ball bearings provide protection from electric current damage, as they can pass through the bearing, and generate less friction than that of steel rolling elements.

How Long Do Electric Motor Bearings Last?

The lifespan of an electric motor bearing depends on several factors — how the electric motor bearings are installed, if the bearings have been properly lubricated with electric motor grease, and how often the bearings are checked for alignment and serviced regularly with preventative maintenance. That’s where IBT Industrial Solutions’ Services Team can help you with making sure you’re getting the best performance out of your premium EMQ bearings. With decades of expertise in servicing industrial applications, our knowledgeable team of experts can help you with anything ranging from installation to engineering services to preventative maintenance to vibration analysis and motion amplification. To keep your operation rolling perfectly within motion, reach out to our industrial service professionals today for the ultimate peace of mind.

More: Top 4 Causes of Electric Motor Failure

NTN Offers the Electric Motor Bearings You Need

With over 75 years in the electric motor field and one of only two bearing manufacturers to ever win the prestigious Deming Prize for global quality management, NTN is committed to improving performance through an unparalleled dedication to quality. NTN offers world-class electric motor bearings that can satisfy the design requirements of smaller applications to wind turbines to gearboxes and everything in between. Each and every one of NTN’s ball bearings meet the standards for electric motor quality for improved overall performance for any system, which makes them one of the premium bearing manufacturers to be trusted by OEMs.

With over 75 years in the electric motor field and one of only two bearing manufacturers to ever win the prestigious Deming Prize for global quality management, NTN is committed to improving performance through an unparalleled dedication to quality. NTN offers world-class electric motor bearings that can satisfy the design requirements of smaller applications to wind turbines to gearboxes and everything in between. Each and every one of NTN’s ball bearings meet the standards for electric motor quality for improved overall performance for any system, which makes them one of the premium bearing manufacturers to be trusted by OEMs.

Visit ShopIBT for Your Bearing & Power Transmission Needs

Purchase your bearing and power transmission products directly on our upgraded e-commerce site, ShopIBT. Featuring a new customer experience, ShopIBT makes it easier than ever to shop online with a faster, more user-friendly check-out experience.

Looking for further guidance on which bearing products would work best for your application’s unique needs? Our dedicated experts are here to help you find the right fit, as well as account for any customizations your system might require. Reach out to a branch closest to you, and we’ll get you up and rolling.