Why spend time, effort and money on high quality precision bearings and sophisticated mounting tools to maximize bearing service life, and neglect lubrication?

In addition, bad lubrication practices do not necessarily result into bearing failures but can lead to inefficient lubrication. For example, relubricating ten times more frequently than needed, results in high grease consumption.

Here are some bad lubrication practices commonly encountered in the field and how monitoring of grease degradation can improve overall lubrication efficiency.

Typical Bad Lubrication Practices

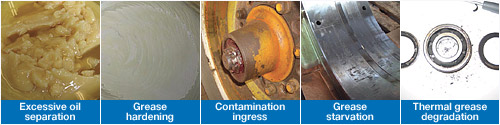

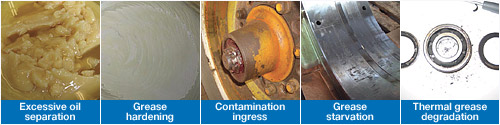

Bad storage conditions: If grease is improperly stored (e.g. shelf life exceeded, contaminated environments, high ambient temperatures), changes in grease mechanical and chemical properties can occur (e.g. hardening, softening, excessive oil separation, oxidation) that influence lubrication efficiency.

Bad handling and contamination ingress: Dirty equipment and tools such as dirty grease guns or follower plates for grease pumps and poor sealing conditions can promote ingress of contaminants into the bearing.

Wrong grease selection: Wrongly selected greases for an application can lead to early failures, but also to inefficient lubrication. The main parameters influencing grease selection are briefly shown below:

Greases operating outside their operating temperature range: Operating and ambient temperatures strongly influence grease selection and degradation. While high temperatures promote grease oxidation and base oil loss, low temperatures might stiffen the grease, promoting lubricant starvation.

Greases operating outside their speed range: The grease base oil viscosity is an important parameter. Lubricant film formation might not be sufficient to separate surfaces and metal to metal contacts occurs at low speeds (in the boundary lubrication regime). The lubricating film may also become too thick under high speeds and viscous forces, as well as friction increase (upper end of hydrodynamic lubrication regime).

This can be illustrated by the curve below:

Since the grease base oil viscosity can change during use, or when base oil is lost due to grease degradation, lubrication can go from one regime to another one.

Also, some applications can exhibit a wide speed range, meaning that the lubricant has to provide lubrication under wide operating conditions (e.g. a gearbox).

Greases without EP/AW (Extreme-Pressure/Anti-Wear) properties under high loads/low speeds: When high loads are combined with low speeds, the lubricating film can become too thin, resulting in metal to metal contacts. Looking at the Stribeck curve, it can be suggested to increase base oil viscosity until a decent film would be formed, but other problems can occur with high base oil viscosities (e.g. start-up at low temperatures). Extreme pressure or anti wear properties are needed to ensure lubrication under boundary conditions.

Wrong lubrication interval and amount of grease: Over and under greasing is quite common and leads to many problems.

The main problems associated with over greasing are: Churning (internal grease friction), temperature increase promoting fast grease degradation, grease softening that can lead to leakage, migration of grease into electrical motor windings and high grease consumption.

The main problems associated with under greasing are: Severe lubricant starvation, dry running, temperature increase and grease degradation.

Grease incompatibility: It is often necessary to change grease in an application. This can be due to reasons such as product being discontinued, bad performances, mistakes and modifications in machine design.

Before performing such a task, the compatibility between greases should be checked first. If greases are incompatible, then the mixture can soften or harden to a large extent, base oil can separate fast and additives can compete with each other.

How to Spot Lubrication Failures?

In the previously mentioned examples, it is clearly seen that bad lubrication practices can lead to lubrication failures. Changes in the grease properties can affect the grease performance through softening, hardening, base oil loss and contamination among others.

So why not check the grease properties and their changes over time?

Specialized laboratories can perform grease analysis and help in avoiding bearing failures. However, when it concerns performing analysis directly in the field (similar to oil analysis), the extensive equipment as well as the expertise are not typically at hand.

The result is that fast support is not feasible and consequently the laboratory option might not be the preferred one.

SKF Grease Test Kit TKGT1

- Collecting information on the application

- Verifying grease sustainability, lubrication intervals and quantities by using SKF LubeSelect and SKF LuBase

- Sampling

- Performing the tests

- Reporting

The tests are easy to perform, fast and cost effective. Important properties like consistency changes, oil bleeding properties and contamination can be checked.

Once the tests are performed, the use of the diagram below helps combining the results. The severity of the problem can be checked and allows a better understanding of the lubrication situation.

Grease degradation severity during operation can be monitored directly in the field, enabling the performance level of the applied lubrication to be determined.

By having more information on the lubrication performance level, bad lubrication practices can be identified in a proactive way.

Wrong grease selection, wrong delivery systems, contamination ingress, bad storage and handling of greases still remain the main root cause of many bearing failures. The SKF Grease Test Kit is an essential first step into improving the situation directly in the field.

Article reprinted with permission from SKF Group.