A gearbox—otherwise known as a gear reducer or speed reducer—is a set of gears that can be added to a motor to decrease speed and increase torque drastically.

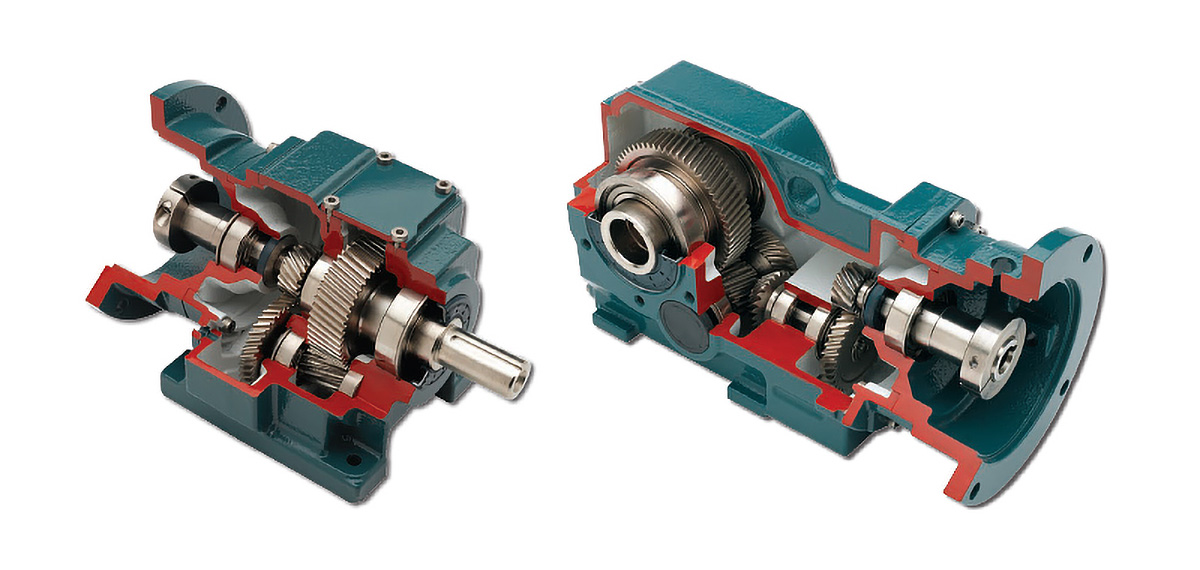

Two standard gearbox configurations are in-line and right angle, though hybrid drives are also available.

➤ In-line models are commonly made up of helical or spur gears, planetary gears, cycloidal mechanisms, or harmonic wave generators.

➤ Right angle designs are typically made with worm gearing or bevel gearing,

Though each gearbox has unique advantages and disadvantages, they all are designed to work in unison with a motor to achieve the desired speed-torque output.

Understanding their function will help you select the best gearbox for your application.

GEARBOXES & TORQUE

The first of two primary purposes of a gearbox is to increase the torque of your motor.

A gear reducer increases the torque of your motor, thus allowing a receiving member to rotate under the impact of a new torque.

Torque is directly proportional to the volume of a motor—diameter squared times length—meaning that a very large motor and a relatively small gearbox could provide the same amount of output torque.

The minimum and maximum torque density that can be supported by each gearbox—expressed in newton meters—varies according to the gear reducer and is indicated by the manufacturer.

GEARBOXES & SPEED

The second purpose of a gearbox is to reduce the motor speed.

For motor-only applications, the slower the motor speed, the larger the motor needs to be. However, large motors can be expensive and may not fit within the available space of an application. Using a gearbox with a smaller motor enables the unit to operate at lower speeds.

To find the best fit for your application, it is essential to determine the ideal reduction ratio for your use. The reduction ratio, given in revolutions per minute, is based on the rotational speed of your motor and is used to determine the output rotational speed. Manufacturers also indicate this information on their product pages.

Once you determine the appropriate torque density and reduction ratio, you should ask yourself what kind of gear reducer assembly is most appropriate for your application.

QUANTIS: STOCKED & READY

The Dodge Quantis product line offers In-Line Helical (ILH) and Right-Angle Helical Bevel (RHB) gear reducers that are dimensionally interchangeable with major global competitors.

The helical gearing found in Quantis reducers is 98% efficient per stage. Paired with a premium efficient motor, the Quantis gear motor minimizes energy consumption while maximizing delivered torque.

Easy installation and removal – The Quantis gearing line features patented installation and removal that provides true value to our customers. In addition, Quantis features an easy method of removing a motor from a gear reducer or removing a shaft-mounted gearbox without causing damage.

Configuration options – The advanced design concept of Dodge Quantis provides flexibility for applications that require the compactness of an integral gearmotor, the durability of a 3-piece coupling, or a shaft input for direct-coupled equipment.

Environmental protection – Quantis gear motors are available with configurable protection levels. These protection levels cover both indoor and outdoor elements with specific features and benefits.

QUANTIS + IBT Build Program

IBT’s Gear Shop offers comprehensive gearbox repair, replacement, predictive maintenance, and design services to a wide variety of makes and models.

Need support? Contact us today or give us a call at 913-677-3151 and we’ll connect you with our team of experts who are standing by to provide you with the best solution for your application.