Many bulk material handling belt conveyor users battle unexpected safety hazards. Couple this factor with decreased productivity and it can be difficult to meet increasing yield goals.

Whether it’s a premature idler failure caused by a contaminated bearing or carryback build up on return rolls, together IBT Industrial Solutions and Martin Sprocket & Gear are to help you overcome operational challenges.

Products by Martin

To help quarries increase yield, improve reliability, and operate safety, Martin offers quality products including:

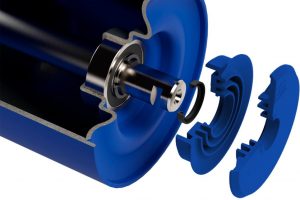

- Idlers: Martin’s industry–leading idler seal design offers maximum protection in dusty and wet outdoor environments.

- Rubber Disc Returns: Provide support to belts on the return side when conveying abrasive materials. The rubber discs flex and offer relief to avoid material build-up caused by excessive material carryback.

- Clean Flight® Wing Pulleys: The patented flight geometry utilizes a screw conveyor concept to effectively eject material to the side of the pulley to protect and clean the belt. Also, the perpendicular flight profile evenly distributes belt tension to prevent wing folding.

Martin at Work

One aggregate producer switched to Martin after experiencing 10 hours of downtime annually as a result of idler failure caused by water and dust contamination. With new idlers, the user found Martin products lasted more than 50 percent longer compared to the previous manufacturer saving $15,000 of annual downtime.

Product longevity can be credited to Martin’s industry-leading triple labyrinth seal which consists of an external shield, flinger, grease-filled seal, and a contact lip seal for protection.

Additionally, this user encountered problems with excessive material carryback and resulted in the belt cutting through the return roll drop brackets.

After turning to Martin, both the Rubber Disc Return Rolls and Clean Flight Wing Pulleys were installed which cleaned the belt by shedding material during operation and prevented sticky material from building up on the roll.

This solution resulted in a higher performing conveyor belt system and a reduction in unscheduled maintenance. In total, the user estimated an annual savings of $36,000 in components and maintenance labor after switching to Martin.

What Are You Waiting For?

Contact IBT’s Director of Conveying Systems Jim Boatright by email or at 913-261-2116 to learn more about the many benefits of using Martin products.