Conveyor systems are vital to the efficient operation of the food and beverage industry. The conveyor belts used in these systems face many challenges, including pulsation, load capacity, temperature changes, and impact resistance. To address these challenges, it is essential to use stronger, thicker belting material and precise sprocket engagement. One solution that has proven effective in the food and beverage industry is plastic modular belting.

Understanding Plastic Modular Belting

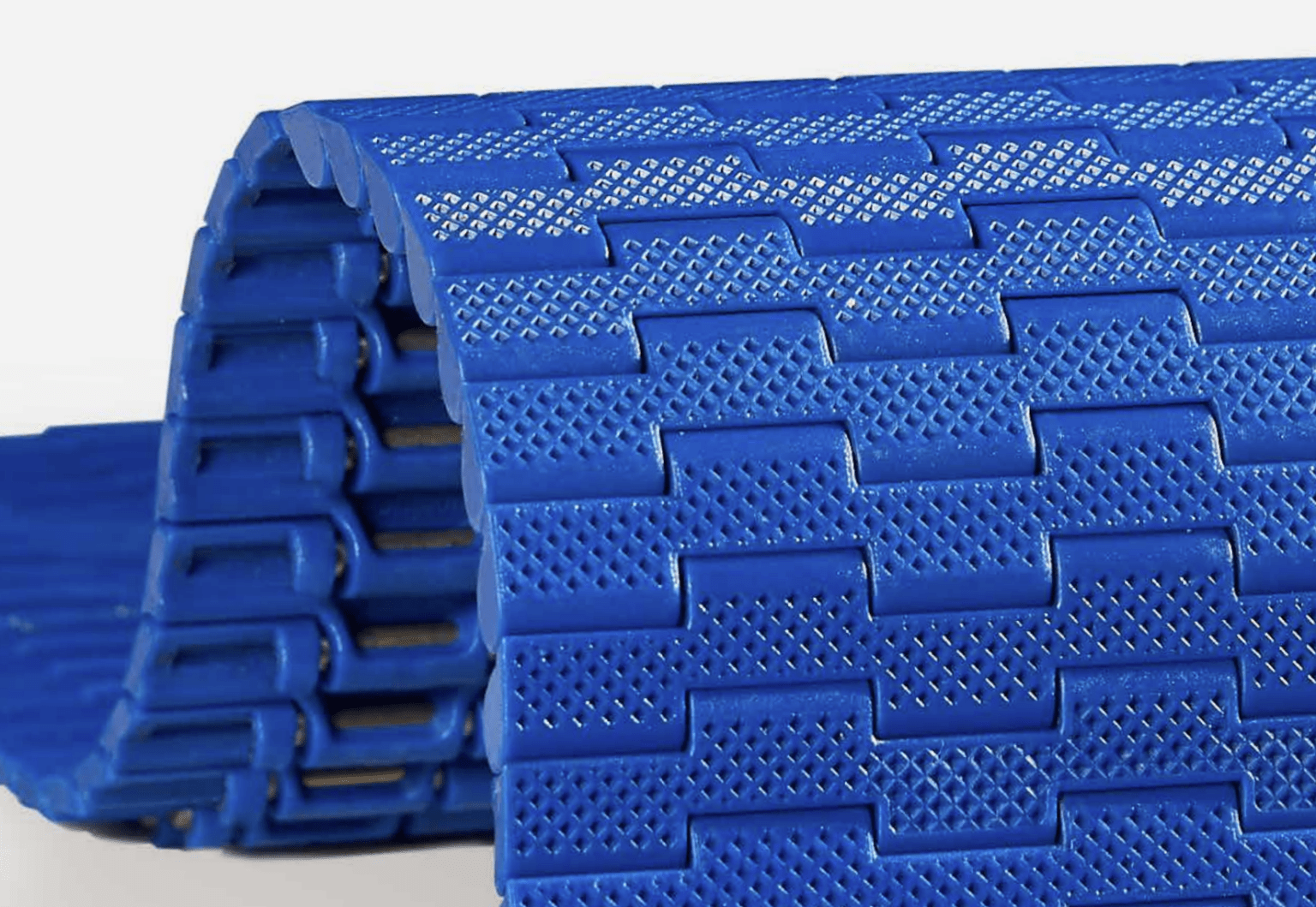

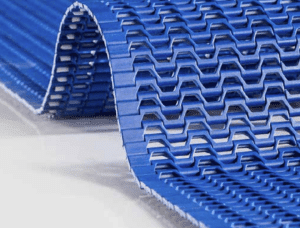

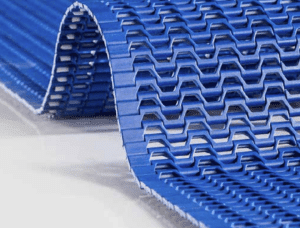

Plastic modular belting differs from traditional conveyor belting in that is made up of interlocking plastic modules that are customizable and easy to clean. This type of belting provides several advantages, including easy maintenance and versatility.

Plastic modular belting differs from traditional conveyor belting in that is made up of interlocking plastic modules that are customizable and easy to clean. This type of belting provides several advantages, including easy maintenance and versatility.

Additionally, plastic modular belting can help solve the common challenges facing conveyor belting in the food and beverage industry, including:

High-Temperature Environments

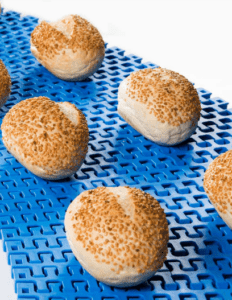

Plastic modular belting is an ideal option for high-temperature environments in industries such as baking and canning. This is because it can be designed to withstand extreme temperatures without losing its physical properties. Compared to traditional fabric conveyor belts, plastic modular belting is more resilient to heat, making them a more reliable option for high-temperature applications.

Ease of Maintenance

The modular design of plastic belting also makes it easier to replace modules in case of damage. This means that if one module is damaged due to product impact or high temperature, it can be replaced quickly without needing to replace the entire belt. This saves time and minimizes production downtime, resulting in increased efficiency and productivity.

Contamination & Bacteria Retention

Additionally, plastic modular belting can be designed with specialized features to ensure proper sanitation in food and beverage processing. For example, the belting can be designed with easy-to-clean surfaces that are less prone to bacterial growth. This makes it easier to maintain high levels of hygiene in food processing facilities, which is essential to ensure that the products are safe for consumption.

The Benefits of Modutech® Plastic Modular Belting from Beltservice Corporation

Modutech plastic modular belting from Beltservice Corporation is specifically designed to meet the unique challenges facing the food and beverage industry. This belting system offers a wide range of benefits, including superior load transmission and belt pull capacity, which helps to minimize unscheduled downtime and increase overall system efficiency.

The precise sprocket engagement of Modutech belting is also a key feature that enhances its performance. This ensures that the belting operates smoothly and efficiently, reducing the risk of jams and other issues that can lead to unscheduled downtime.

Modutech belting also offers excellent hygiene and cleaning properties, which are essential in the food and beverage industry. The belting is designed with a smooth, easy-to-clean surface that is resistant to bacterial growth and contamination.

Overall, the combination of enhanced belt strength and precise sprocket engagement makes Modutech plastic modular belting from Beltservice Corporation an ideal choice for the food and beverage industry. It is designed to provide reliable, efficient, and hygienic conveying operations, helping to increase productivity, reduce downtime, and improve overall system performance.

IBT is Your Trusted Partner for Conveying Solutions

If you’re looking for a specific conveyor belt component and would like to purchase your solution directly, visit ShopIBT.com to access the conveying products we have available online.