Navigating compliance, regulations, and consumer demands in the food and beverage industry can be exceedingly difficult for processing plants, especially when the landscape is ever-changing. That’s why manufacturers and producers in the food and beverage industry need premium products that they can trust will meet the stringent requirements and withstand the corrosive environments. Discover how high-quality, corrosion-resistant deep groove ball bearings can help those in food and beverage processing improve food safety and machinery uptime.

Face Frequent Washdowns Head-On with Corrosion-Resistant Bearings

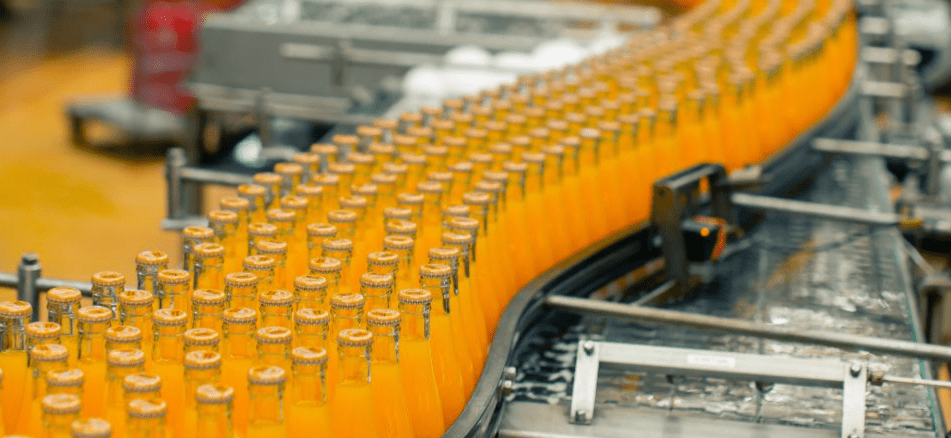

From highly concentrated chemicals and sanitizers to rust and mildew forming from constant washdowns to high levels of humidity, the harsh environments in the food and beverage industry can not only be unforgiving on materials and equipment, but can also cause contamination. Due to this, the risk of contamination can happen along any point throughout production, processing, and distribution.

With products like corrosion-resistant deep groove ball bearings from Timken®, you can maintain optimum operating efficiency, despite chemical washdowns and wet environments, with stainless steel rings, balls, and cages that are designed to handle corrosive conditions. With a variety of configurations, including standard, thin-section, narrow, and miniature deep groove ball bearings, Timken provides an array of solutions for poultry deboning machines, conveyor rolls, form fill seal machines, filling and seaming equipment, combination weighers, labeling equipment, and more.

Reduce Maintenance for Bearing Lubrication

With the wet environments and frequent washdowns in food and beverage processing plants, bearings can start to lose their grease, which causes unpredictable downtime due to bearing lubrication. Eliminating the need for re-greasing can help you avoid costly shutdowns and change-outs. That’s why lubricants that have a micro-porous polymer structure that contain high-performing oils and additives, like Timken’s FVSL613 Solid Lube, can be a great alternative to grease.

When coupled with Timken’s deep groove ball bearings, a high-performing grease alternative, like FVSL613 Solid Lube, can further guard against contaminants for safe and reliable operation. Providing an innovative solution for the uncompromising environments in the food and beverage industry, Solid Lube completely fills the free volume between the races, rolling elements, and cage, while releasing the appropriate amount of oil to lubricate the rolling elements during bearing rotation. This allows for consistent bearing lubrication and line of defense against contamination to help increase machinery uptime and reduce maintenance costs.

Meet Demanding Food Safety Standards & Performance Requirements

With the right products, your team can meet the most stringent regulatory compliance and FDA approval. Elevating your food and beverage processing with solutions that are corrosion-resistant and stainless steel, you’ll be able to decrease the risk of contamination and the amount of maintenance for your crew.

Embracing the latest material science technology and innovation in manufacturing, Timken produces thoughtful deep groove ball bearing designs and lubrication solutions to help manufacturers in the food and beverage industry maintain food safety standards and maximize their operational efficiencies. That’s why IBT Industrial Solutions is proud to partner with an industry-leading brand like Timken, to provide you with the ultimate peace of mind and return on investment.

Get Corrosion-Resistant Deep Groove Ball Bearings on ShopIBT

If you’re ready to optimize your food and beverage processing plant with corrosion-resistant, stainless steel ball bearings from Timken, visit ShopIBT to purchase the right solution for you directly!

If you’re in need of customized, end-to-end solutions that are unique to the food and beverage industry, reach out to our dedicated team of knowledgeable experts to discuss your options today.