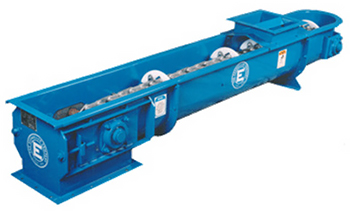

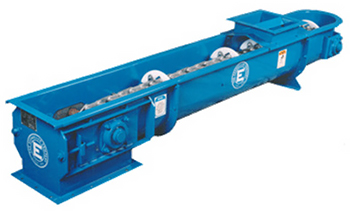

Drag Chain Conveyor Systems and Products

IBT wants to work with you to design drag chain conveyor systems that meet your specific business needs. In addition to the partnerships we’ve built with leading manufacturers like Essmueller and Schlagel, our knowledgeable team of conveying systems experts will ensure that you receive quality service, parts, and, ultimately, a reliable drag conveyor system to maximize your throughput.

Our team will make sure your system has the capabilities to efficiently handle your workload. Tell us how we can help you. We provide an abundance of options, including:

- Thicker UHMW Paddles

- Split Hubs

- Roller Chain

- Trough Liners With UHMW Or Abrasion-Resistant Steel Plates

- Bypass Inlets

- Bend Sections

- Discharge Gates

- Safety Monitor Systems

- Rail Returns

- Divided Troughs

- Flame Cut Hardened Steel Sprockets

Drag Chain Conveyor Systems Design

Drag Chain Conveyor Systems Design

Drag conveyors have capacities ranging from 1,000 BPH up to 60,000 BPH and can run horizontally or inclined with special applications, such as L-Path drag conveyors. You have the option to select from painted steel, galvanized or stainless steel, and either a round or flat bottom design. Standard features of a drag chain conveyor system include:

- Steel or Cast Iron Sprockets

- External-Mount Pillow Block Bearings

- 12 Ga. Metal Trough

- 14 Ga. Flat Weather Covers

- Stress-Proof Shafts

- UHMW Paddles Mounted on Heavy-Duty Chain

- UHMW Return Rollers

Benefits of Drag Chain Conveyor Systems

Drag chain conveyor systems offer numerous benefits, making them an excellent choice for various industries. They are durable, flexible, and capable of handling a wide range of materials. These systems have high throughput capacity, leading to increased productivity.

Some benefits of drag chain conveyor systems include the following:

- Customize your grain storage system according to your preferences.

- Minimize breakage due to very little metal-to-grain contact.

- Avoid internal disturbances or pressure on materials.

- Require less horsepower compared to screw conveyors.

- Eliminate dust and moisture issues with enclosed and sealed conveyors.

- Occupy less space per bushel conveyed due to their lower profile.

- Benefit from a maintenance-friendly tail section.

- Discharge loads at any opening as needed.

Drag Conveyor Parts

Before designing a drag conveyor, you need to understand the different parts and how they work. All components are available for both flat and round bottom conveyors.

- Chain: The chain is a strong and connected series of links that moves the material along the conveyor.

- Paddles: Paddles are attached to the chain and help move the material efficiently.

- Flights: Flights are similar to paddles and provide support and control for the material being transported.

- Sprockets: Sprockets are toothed wheels that rotate and drive the chain, making the material move along the conveyor.

- Troughs: Troughs are the channels where the material flows and are designed to guide and contain the material during transport.

- Lids: Lids cover the trough to protect the material from dust, moisture, and other contaminants.

- Lining: The lining is a protective layer inside the trough that reduces friction and wear, extending the life of the conveyor.

- Materials: Drag chain conveyors can handle different types of materials, like grains, powders, and bulk solids, using components designed for each material’s characteristics.

- Conveyor Chain: The conveyor chain is made up of the chain, paddles, and flights working together to carry and move the material efficiently. With this, we have the ability to provide the specified attachment brackets with required fasteners.

Drag Conveyor Replacement Flights

The UHMW flights are a top choice for the grain industry due to their strength and ability to withstand abuse in these demanding environments. Their durability has been proven time and again. The abrasion-resistant material has the ability to “flex and give” tremendously, and with less friction, reduce workloads on drives and motors, in addition to reducing the wear on flights and the trough.

The white UHMW flights are ideal for food handling due to their naturally slick surface and compliance with Food Additives Laws and Regulation No. 177.1520. They are an obvious choice with their low initial cost and longer operational life, minimizing downtime and, ultimately, saving you money long term, as well.

About IBT’S Conveying Systems Group

As specialists in the conveying systems field, IBT Industrial Solutions understands the importance of good systems application in achieving optimum efficiency. With our years of experience in providing conveying systems and components, you can rely on IBT for the best solution to your problems.

Email Jim Boatright, the Conveying Systems Business Group Director at IBT, to learn more about our drag chain conveyor systems expertise.

INTRODUCING AN UPGRADED ONLINE SHOPPING EXPERIENCE – SHOPIBT!

OFFERING YOU THE BEST PRODUCTS IN EVERY CATEGORY

FROM THE BRANDS YOU CAN TRUST

Discover the benefits of the

FREE IBT Advantage Program

Wondering what makes IBT great?

Don’t just take our word for it.

Get in touch for help and information

Our head office address:

9400 W 55th St, Merriam, KS 66203

Call for help:

(913) 428-2858