A commercial U.S. bakery producing loaves of bread had a problem: their bearings kept failing every 6-8 months. Even after relubricating every 2 weeks—which created a tremendous burden for the maintenance staff—the bearings still failed repeatedly.

More: Why Do Bearings Fail?

After installing Sealmaster high-temperature bearings with an expansion design on one side using a reduced maintenance design that did not require lubrication, the company saved over $50,000/year in the costs associated with relubrication, labor, equipment damage, and lost bread product.

Those same Sealmaster bearings have now been running for 6 years without replacement or problems.

“These bearings work extremely well in food processing plants, on sorters, sizers, even 400-degree ovens,” said Ian Rubin, the Director of Marketing for Mounted Bearings at Power Transmission Solutions, the maker of Sealmaster. “A customer who is looking for 4-5x more life on their bearings can often get 10x more life when they switch to a higher-performance bearing.”

More: Where Are Your Bearings Coming From?

5,000+ Mounted Ball Bearings Available

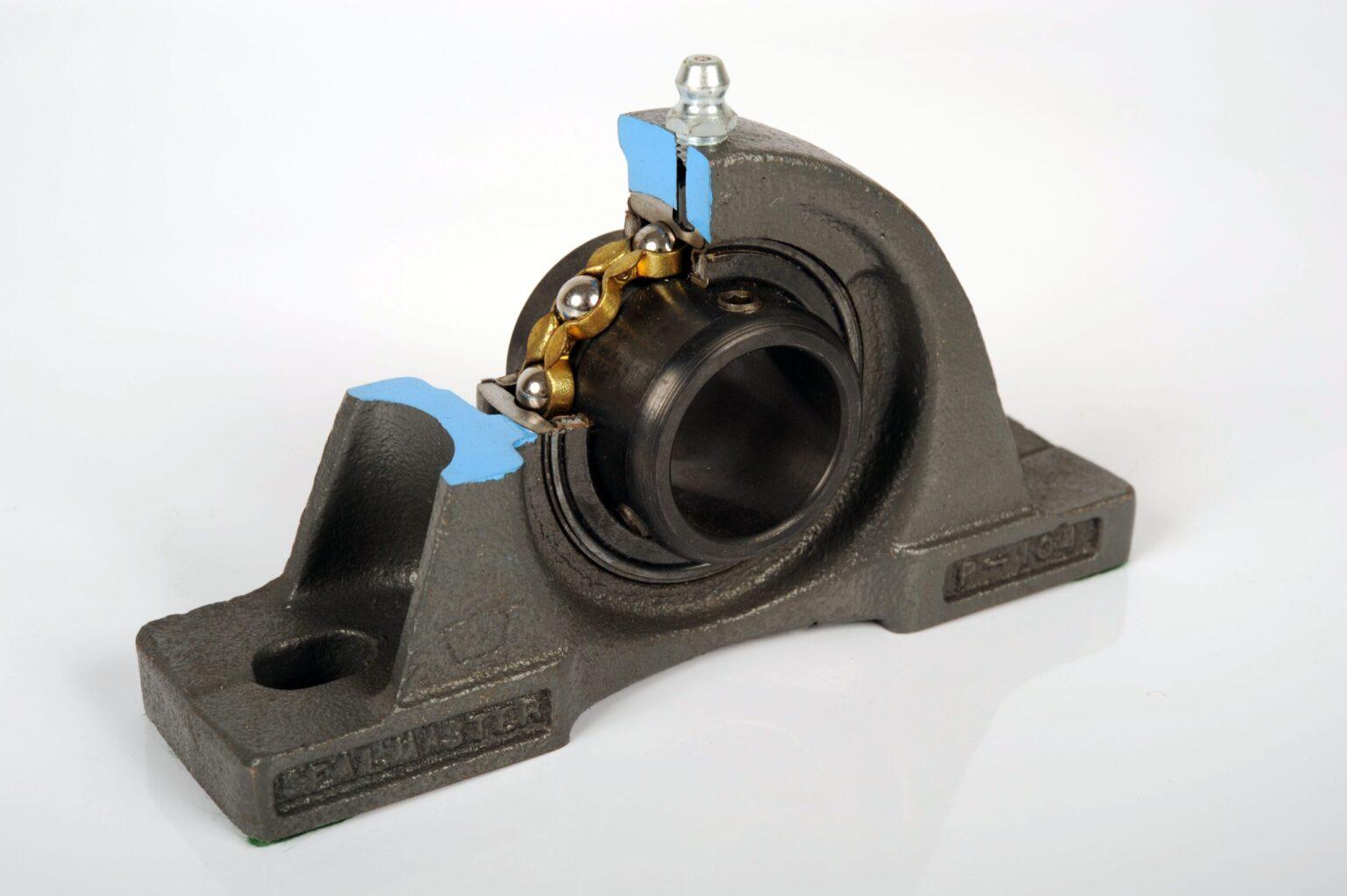

Sealmaster offers more than 5,000 mounted ball bearing SKU’s—and frequently makes custom bearings for specific applications.

“We may be a little more expensive than other bearings, but the product works and it lasts a long time, reducing the total cost,” Rubin said. “Give us your toughest application, and we’ll find a bearing that outperforms most competitive mounted ball bearings. We can also customize our mounted ball bearings to meet specific application requirements with different seals, lubricants, or locking mechanisms, for different speeds, or different temperatures.”

Sealmaster produces a wide variety of bearings, including:

- Mounted ball bearings

- Mounted spherical roller bearings

- Mounted tapered roller bearings

- Corrosion resistant bearings

- Cylindrical OD bearings

- Rod end bearings

- Spherical plain bearings

Why Sealmaster Mounted Ball Bearings Work So Well

Sealmaster bearings have been used successfully for everything from food processing, to bottling, agriculture, and even sand and stone quarries. They perform exceptionally well in situations where there are dirty environments, heavy loads, or repeated shock loads.

The reason? Rubin points to the unique outer ring design.

“The wide outer ring is a foundation of the overall design that we use, giving us more design options,” he said. “It has more grease capacity, unique retainer design and lubricates more efficiently than other bearings. It also has more room for enhanced sealing options. The result is greater uptime and cost of ownership.”

More: Bearing & Power Transmission Academy

Get Sealmaster bearings

Contact Tim Zerger, Director of Bearings and PT for IBT Industrial Solutions, at (913) 261-2140 or tim_zerger@ibtinc.com.