A hose assembly is more than just the fitting and hose retention method; It’s also crucial to know the application requirements. That’s why, PT created a “Hose Shank Guide” to help you narrow down which shanks are best for your application, provide more information on recommended hose retention methods and outline safe assembly practices.

Shank-to-Hose Matching

The shank is the cylindrical component of the fitting that fits into the hose, joining the fitting and hose together. Understanding the various shank profiles can help you best match the fitting to the hose, and ultimately, the hose to your application.

Below is an overview of three standard hose shank styles. For additional features and benefits of these shank styles and more, and to learn how they’re best used for different retention methods, click here.

HOSE SHANK STYLES

- STANDARD – The Standard Shank is the most common and recognized shank, which meets a majority of application requirements around the globe.

- LOW PROFILE – The Low Profile Shank features unique trapezoidal barbs that are less aggressive on hoses with sensitive ID’s, such as PTFE lined hoses.

- UNDERSIZED – The Undersized Shank is for hoses with smaller ID’s than standard hoses.

- + MORE

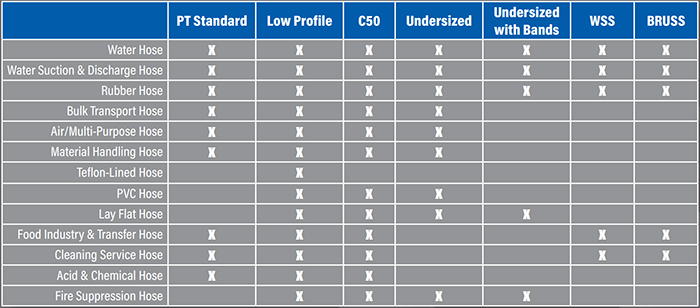

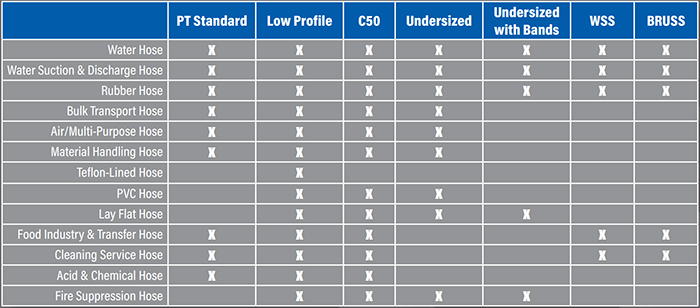

Each shank’s profile provides a different feature for the hose for which it was designed. Refer to the table below when selecting a shank style for your hose application.

More: Learn More About 3-A Food & Dairy Hose Standards

Hose Retention Methods

Hose retention methods, including banding and crimping, use clamps, sleeves and ferrules to secure the fitting to the hose and help the assembly meet various application requirements. Each shank has a unique profile that helps mate the fitting and the hose for a secure seal.

- Banding – Banding clamps, typically ⅝” wide, require the use of simple banding tools and offer an economic solution for hose retention.

- Available in stainless steel, galvanized stainless steel or other metals, PT recommends Punch-Lok®’s extensive, high-quality banding product line that has every solution needed in hose banding applications.

- Crimping – Crimping sleeves and ferrules offer a more permanent solution for hose retention, holding tighter and lasting longer.

- PT’s ProGrip line of sleeves and ferrules are the toughest in the chemical, sanitary and industrial applications. Each sleeve or ferrule has greater structural integrity due to their extended manufacturing process. PT’s C50HD ferrules are available with a serrated internal ID for extreme chemical and petroleum applications.

More: See How Our KC Hose Shop Is Turning Skeptics Into Believers

Safe Assembling With STAMPED

IBT is committed to keeping hose assemblers, users and the environment safe. NAHAD’s Hose Safety Institute has released the STAMPED guide program to ensure the safe way to build and assemble industrial hoses. When assembling your hose, please use safe practices and follow the HSI standards to help us keep that vision of creating a safer work environment.

STAMPED is:

- Size – I.D. and length of the hose + any O.D. constraints for the assembly.

- Temperature – Material temperature conveyed through the hose and the environmental conditions.

- Application – The conditions of use for the assembly.

- Material – The media being conveyed, its type, and concentration.

- Pressure – the assembly pressure that needs to be maintained.

- Ends – Style, type, orientation, and attachment methods.

- Delivery – testing requirements and other requirements related to the customer.

For more information on safe practices when assembling hoses, visit NAHAD.org.

Now Stocking Standard Shanks & Crimping Up To 6”

IBT stocks PT’s Standard Hose Shank from ½” to 6” in aluminum and stainless steel. Looking for hose service experts? Our certified hose shop in Kansas City can crimp up to 6” and build complete, safe and sanitary assemblies in-house. Learn more about our hose product and service offering or contact us today!