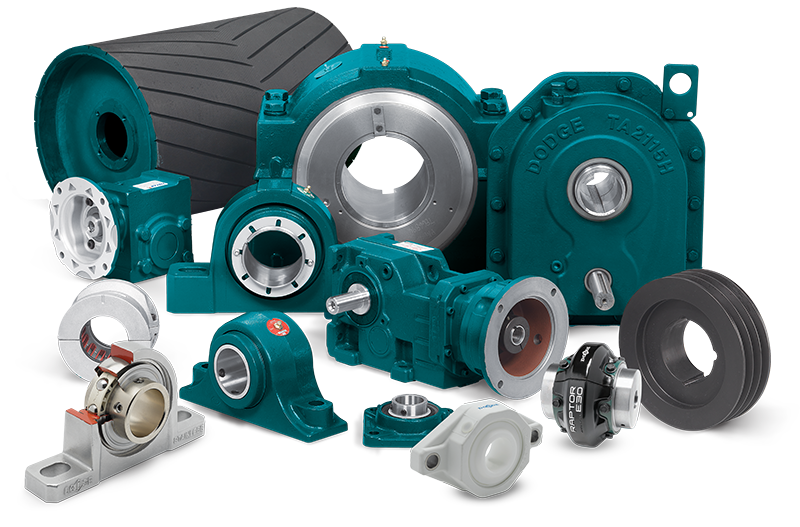

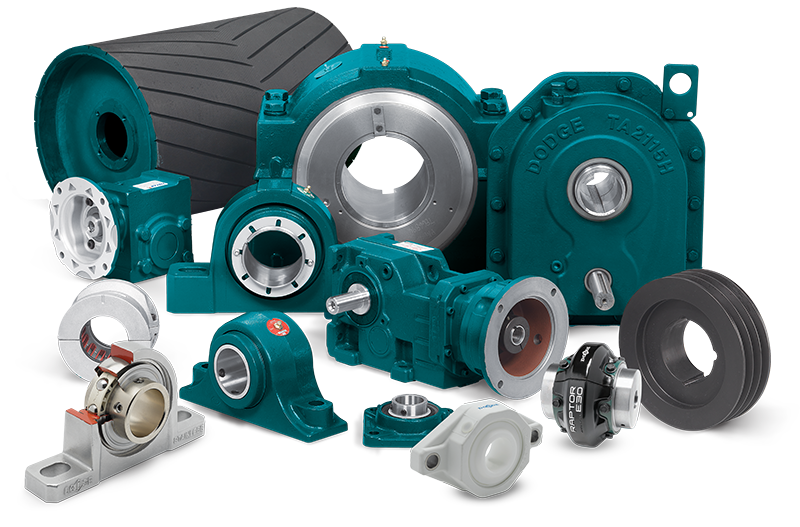

An RBC Bearings company, Dodge® Industrial is a leading manufacturer of mounted bearings; enclosed gearing; mechanical drive components, couplings, and conveyor components; as well as innovative IIoT technologies. For more than 140 years, Dodge products have helped increase the productivity and profitability of industry operations. Ongoing innovations and advanced technologies continuously help manufacturers improve output, decrease downtime, and enhance system value to their customers.

To learn more about Dodge products, go to dodgeindustrial.com

Keep up to date on product news and latest offers.

Copyright © 2024 All rights reserved by IBT Industrial Solutions