Elevating Industry Standards: Deep Groove Ball Bearings and the Power of Schaeffler’s FAG Generation C

Deep groove ball bearings play a crucial role in various industrial applications by quietly facilitating the smooth rotation of machinery. These unassuming components play a pivotal role in ensuring the efficiency and reliability of countless processes. However, they are not without their challenges. In this blog, we’ll explore some of the common issues users encounter […]

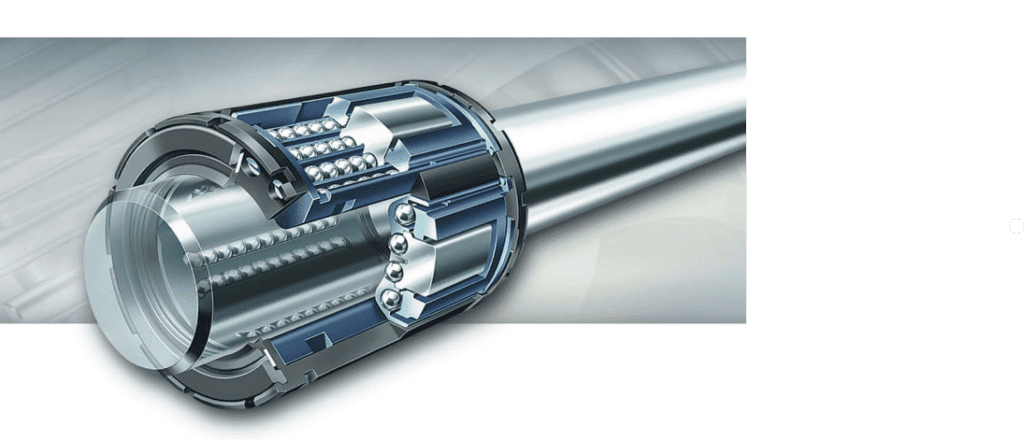

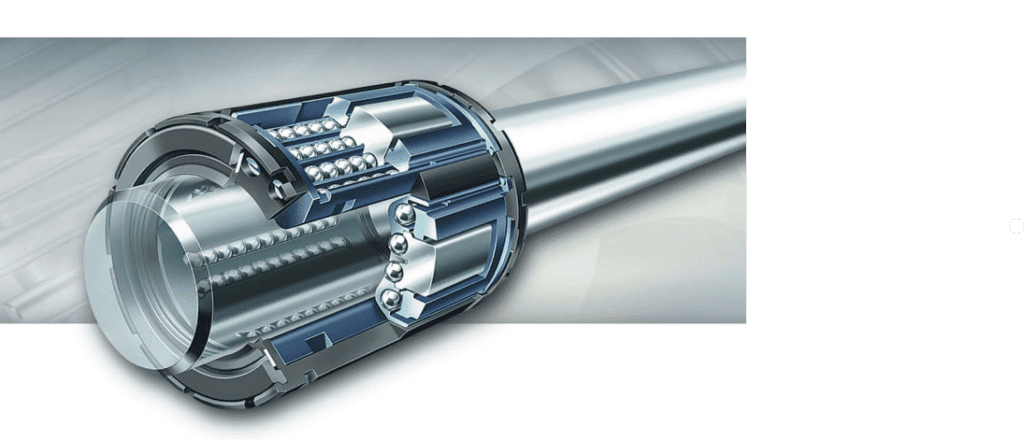

Maximizing Efficiency and Precision with Linear Ball Bearings and Round Shaft Guidance Systems

When it comes to industrial manufacturing, smooth and precise linear motion is essential to ensure accurate positioning, load capacity, and minimal friction. Linear ball bearings and round shaft guidance systems are common solutions for achieving these requirements. In this blog, we’ll take a closer look at linear round shaft guidance systems and their applications in […]

Decrease Unplanned Downtime for Your Operation with FAG Split Cylindrical Roller Bearings from Schaeffler

One of the most costly and time-consuming elements in an industrial operation is caused by bearing replacement. That’s why Schaeffler’s new FAG Split Cylindrical Roller Bearings are designed specifically to eliminate many of the steps and complications involved in replacing conventional solid bearings. In this article, we’ll take a closer look at how Schaeffler’s new […]

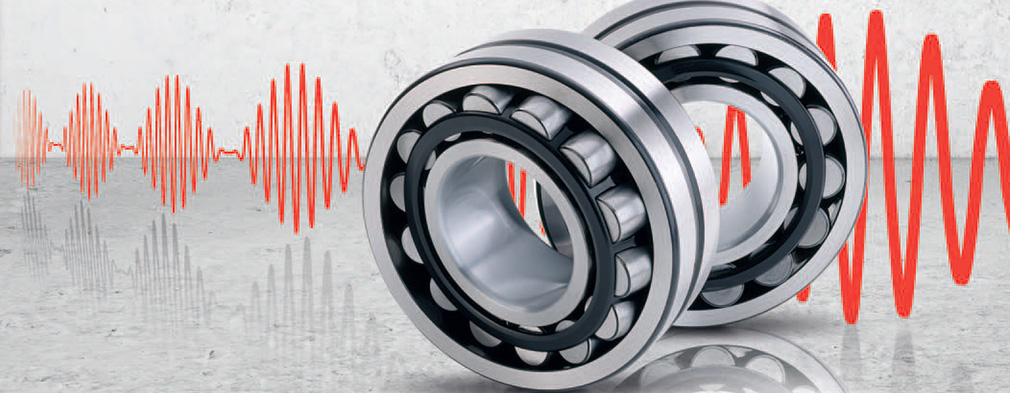

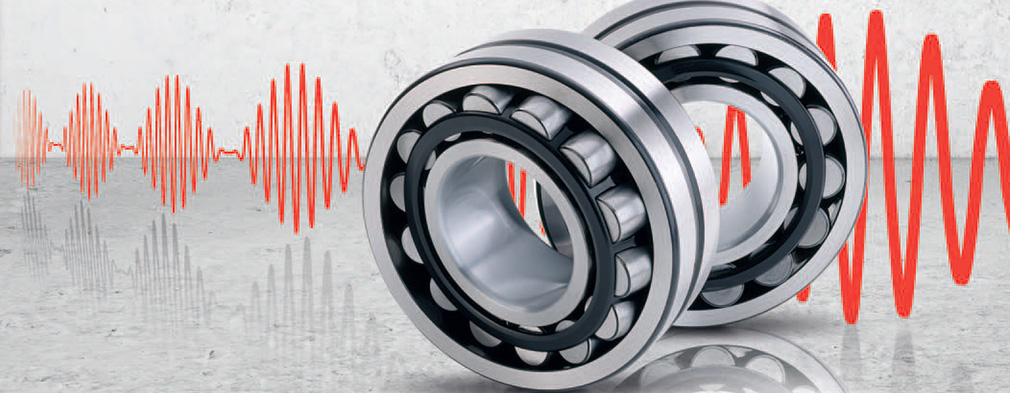

Roller Bearings that Can Handle the Heft of Vibratory Applications

Nothing quite compares to the severe stresses that bearings are subjected to when it comes to vibratory applications. Vibrating screens and other vibratory machinery, such as road rollers and saw frames, cause excessive wear over time on the roller bearings that support them. That’s why spherical roller bearings are designed to deliver superior performance for […]

Bearing Replacements Costing You Downtime? Time for Cost Savings You Need & Deserve!

Bearing replacements have you in a tight spot? Do you deal with rapid bearing replacement, in areas that are challenging to work in or hard to reach? Replacing bearings can be a tedious and time-consuming process, and taking extra steps to do your work, when you don’t have to, is the opposite of efficiency. Solution? […]

Schaeffler’s Corrotect Coating Systems – Preventing Corrosion & Increasing Bearing Life

Are you tired of battling corrosion with your rolling bearings? Corrosion is a common issue with rolling bearings…. That’s right, you’re not alone in this issue. Not only is corrosion common, but it is actually one of the most frequent causes of rolling bearing failure. Rolling bearings are vitally important to the operation of equipment […]

How to Prevent Contamination with a Reliable Bearing Seal

In harsh operating environments, bearings are constantly under attack from contaminants such as dirt, abrasive materials, caustic chemicals, extreme heat, and heavy shock loads. Because of this, selecting the right bearing seal to protect against contamination is often the most important consideration when choosing a bearing and housing assembly. To ensure efficiency in your facility, […]

What You Can Expect from Schaeffler’s X-life Bearings

X-life is the seal of quality for high-performance products from the INA and FAG product brands that are manufactured by Schaeffler, one of the world’s leading integrated industrial and automotive suppliers. Rolling bearings are vitally important to the reliable and cost-effective operation of machinery and equipment in a wide range of industrial applications. Combined with […]

Investigating Bearing Failure—Spot The Clues & Uncover The Root Cause

According to Schaeffler, 85% of bearing failures are preventable. Learn how to spot the clues to eliminate the problem from the source and maximize your bearing life. Rolling bearings are at the heart of most machines and vehicles. When the bearing goes, the machine or vehicle stops. However, the bearing is often the “victim” and […]

Put An End to Costly Current Damage With Current-Insulated Bearings

Wheelsets and traction motors (rail vehicles), DC and AC motors (drivetrains), and generators (wind power) can all be exposed to electric current—which can be extremely harmful to roller bearings. While it is very difficult to eliminate the causes of bearing voltages that are induced by the motor, it is possible to avoid bearing damage with […]