Machinery and equipment downtime for scheduled and unscheduled maintenance can lead to loss of productivity and money. For this reason, all industrial facilities use some sort of flexible couplings for pumps, compressors, conveyors, and other power-operated equipment to prevent damage in the event that torque overload occurs.

Jaw-in-Shear (JIS) couplings offer a lot of benefits over standard coupling options.

5 Benefits of Jaw-In-Shear Couplings

Could your plant benefit from using jaw-in-shear (JIS) couplings? This flexible coupling is very powerful and solves a number of operational challenges.

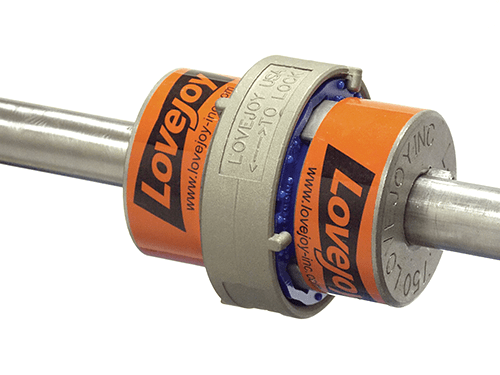

“The jaw coupling is one of the most widely used flexible couplings in the power transmission field,” said Charlie Mudra, the Distribution Channel Manager for Lovejoy, Inc., adding that the original jaw coupling from Lovejoy dates back to 1927, while the JIS version was developed in 1998. “It’s found just about everywhere,” he says. “The variety of applications for this design is quite wide.”

Lovejoy’s jaw-in-shear coupling is robust, flexible, economical, non-fail safe, requires no grease, and is maintenance-free.

Here are five benefits of a JIS coupling and how it can help your operations.

1. Flexible Alignment

JIS couplings allow for greater flexibility when connecting unaligned shafts. They can accommodate this misalignment between motor and compressor, pump, generator, conveyor, mixer, fan, and more.

You get more robust angular and parallel misalignment capacity over the standard jaw design. With Lovejoy’s JIS coupling, for example, angular misalignment increases from one to two degrees, while parallel misalignment increases from 0.010 inches to up to 0.094 inches, so it’s much more forgiving.

2. Easier Coupling Replacement

The Lovejoy JIS design uses a wrapping element called a “spider” that makes it easy to take off and replace. Normally, either one or the other hub would need to be replaced, but the spider element allows technicians to access the coupling easily. This element is held in place by a locking collar that eliminates the need to loosen set screws. The simpler design reduces tool usage and makes change-outs quicker and easier.

3. Non-Fail Safe Design

The JIS has a non-fail safe design, which means that the coupling will not transmit torque if the spider element fails. If there is a failure, the spider element is easy to replace and doesn’t need either coupling hub to be removed. Because it is non-fail safe, if the spider fails, it is not compressed between the interlocked jaws of each coupling hub. The coupling has the hubs drawn apart with jaws aligned axially. Being able to remove the spider radially saves significant maintenance time and money.

4. Longer Coupling Service Life

Lovejoy’s JIS couplings use 50D Shore urethane, with a temperature rating similar to rubber, but with better chemical resistance. Plus, urethane provides 1.5 times better torque carrying capacity versus rubber, giving you longer life and less frequent replacement.

5. Maximized Inventory and Reduced Component SKUs

The Lovejoy JIS couplings use the same hubs as the standard jaw coupling, so you don’t have to buy a bunch of new parts. You’re actually only adding two additional SKUs for the retaining ring and element. This is very different from other designs, which require a specialized hub.

Stainless Steel Coupling Retaining Ring

Lovejoy offers a JIS design that uses an entirely stainless steel retaining ring. When paired with their hub, you can create a completely stainless steel assembly—perfect for the food and medical industries. In fact, Lovejoy offers five sizes of hubs made from either stainless steel castings or stainless powdered metal.

About Lovejoy, Inc.

Lovejoy, Inc. has been known since 1900 as the world leader of quality flexible shaft and specialty couplings for the power transmission industry. With a selection of more than 20,000 couplings in different sizes and shapes, Lovejoy covers the needs of virtually every market.

Need a Lovejoy JIS coupling? Contact Tim Zerger, Business Group Director of Bearings and PT at IBT Industrial Solutions, at (913) 261-2140, or tim_zerger@ibtinc.com.