The implementation of industrial automation systems involving various technologies like industrial robots, machine vision systems, and advanced sensors, can be used to automate a wide range of manufacturing tasks. Assembly, material handling, quality control, and packaging are just some examples of processes where industrial automation is important.

Today, we’ll discuss what exactly industrial automation is and why it’s vital in the manufacturing field.

What Is Industrial Automation?

Industrial automation refers to the use of advanced technologies to control and automate certain manufacturing processes. Overall, automation technology can help improve efficiency, reduce costs, and enhance product quality, making it an important part of modern manufacturing. It can also prevent workplace injury by improving the safety of the manufacturing environment.

Computerized control systems, sensors, and other tools to operate and control machinery and equipment in industrial settings are all important parts of automation technology. There are many different types of industrial automation technology, as well, which can include the following:

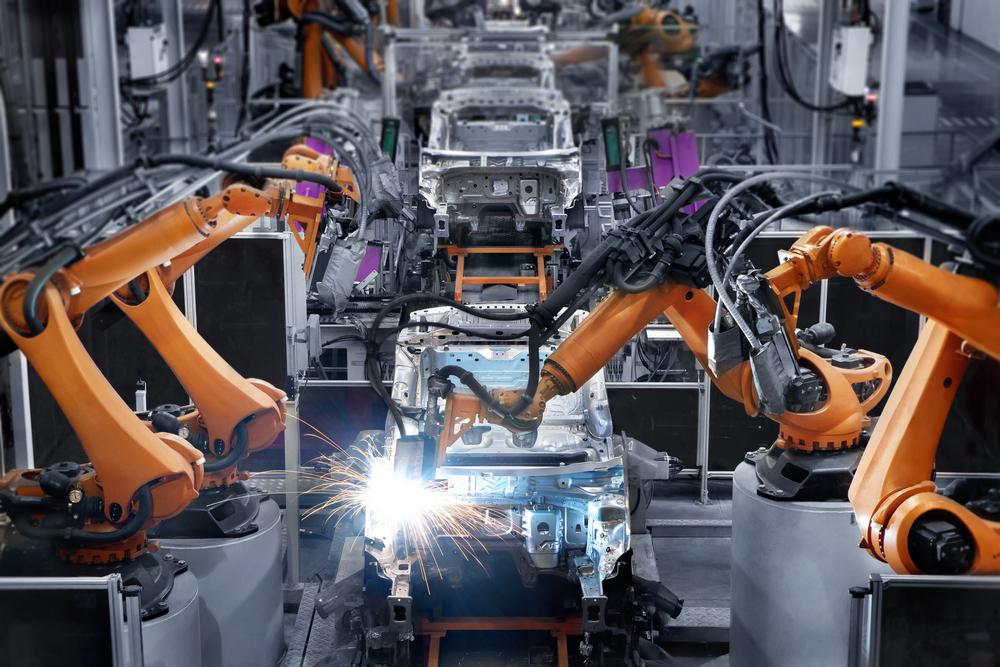

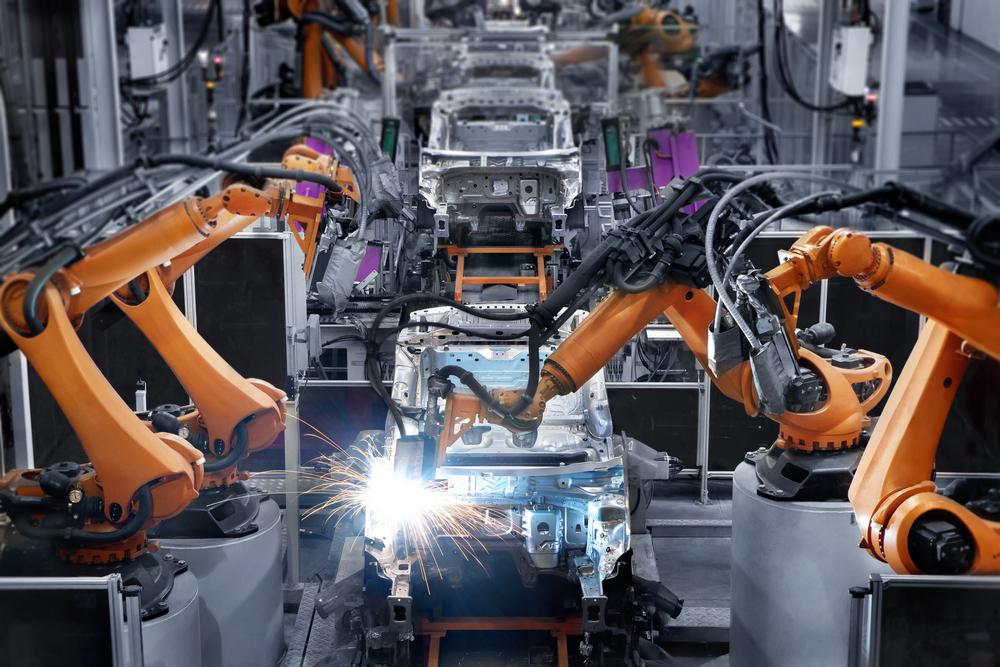

- Robotic: Robotic automation involves using robots to perform tasks that would otherwise be performed by humans. These robots can be programmed to perform a wide range of procedures, from simple assembly to complex manufacturing processes. Robotic automation is commonly used in industries such as automotive manufacturing, electronics, and pharmaceuticals.

- Fixed: Fixed automation, also known as hard automation, involves using specialized equipment to perform a specific task or series of tasks. These machines are typically designed to produce a single product and can be expensive to modify or reconfigure. Fixed automation is commonly used in high-volume production lines for products like cars, appliances, and electronics.

- Programmable: Also known as soft automation, programmable automation uses computer-controlled machines to perform tasks. These machines can be easily reprogrammed depending on the task at hand, making them a more versatile automation option. This type of automation is ideal for small-scale production lines that require frequent changes in the manufacturing process.

- Flexible: Flexible automation is a combination of fixed and programmable automation. It involves using specialized equipment that can be quickly reprogrammed to perform a variety of tasks. This type of automation is ideal for manufacturing lines that produce multiple products or where the production process needs to be changed frequently.

- Integrated: Integrated automation is a comprehensive system that combines various types of automation to optimize the manufacturing process. It includes machines, sensors, and software that work together to control the production line. This type of automation is used in industries that require high levels of precision and accuracy, such as aerospace and medical device manufacturing.

- Artificial Intelligence (A.I.): A.I. automation uses advanced algorithms and machine learning to optimize the manufacturing process. It can help identify inefficiencies, predict maintenance needs, and improve overall efficiency. This type of automation is still in the early stages of development but has the potential to revolutionize the manufacturing industry.

4 Benefits of Industrial Automation

Industrial automation has become increasingly important in recent years, as it offers a range of benefits to businesses and the wider economy as a whole. Automation can make the manufacturing environment safer, more efficient, and more cost-effective. And while there are many benefits of automation, here are the top four.

1. Increases Productivity

One of the key benefits of industrial automation is its ability to increase productivity. Automation allows businesses to produce goods and services at a faster rate, with greater consistency and accuracy. This means that manufacturing tasks can be performed at a much higher level than what a human worker could do, leading to faster production times and increased output.

Additionally, automation can operate around the clock, which allows for 24/7 production. This can help reduce costs and improve productivity, which in turn allows businesses to remain competitive in the global marketplace.

2. Improves Quality Control

By automating tasks such as inspection and testing, industrial automation can help improve quality control and enhance customer satisfaction. By using sensors and other forms of automation technology, businesses can monitor and control the production process more closely, ensuring that products are of consistent quality and meet customer expectations.

Not only does this lead to better brand reputation, but it also builds customer loyalty, which can be crucial in competitive industries.

3. Enhances Workplace Safety

Automation allows businesses to reduce the risk of accidents and injuries in the workplace. Instead of human workers performing tasks that may be dangerous or physically demanding, machines can take on these responsibilities instead. This protects the health and well-being of workers by lowering the chances of workplace injuries and accidents, while also reducing the risk of legal liability for businesses.

4. Reduces Costs

Although the initial investment in automation can be expensive, the long-term benefits of increased productivity and reduced labor costs can lead to significant savings over time. Automating manufacturing processes allows businesses to reduce the amount of raw materials and energy required to produce goods, also reducing the amount of waste generated during production.

Ultimately, this not only improves environmental sustainability during the manufacturing process, but it can also lower costs—a concern that is ever-increasing for businesses and consumers alike.

Overall, industrial automation technology plays an important role across many different industries and can work to improve both profitability and competitiveness in the global marketplace. As technology continues to advance, we can expect to see even greater use of automation in product production as businesses seek to capitalize on its many benefits.

Interested in learning more about industrial automation? Contact our experts at IBT today to learn more!