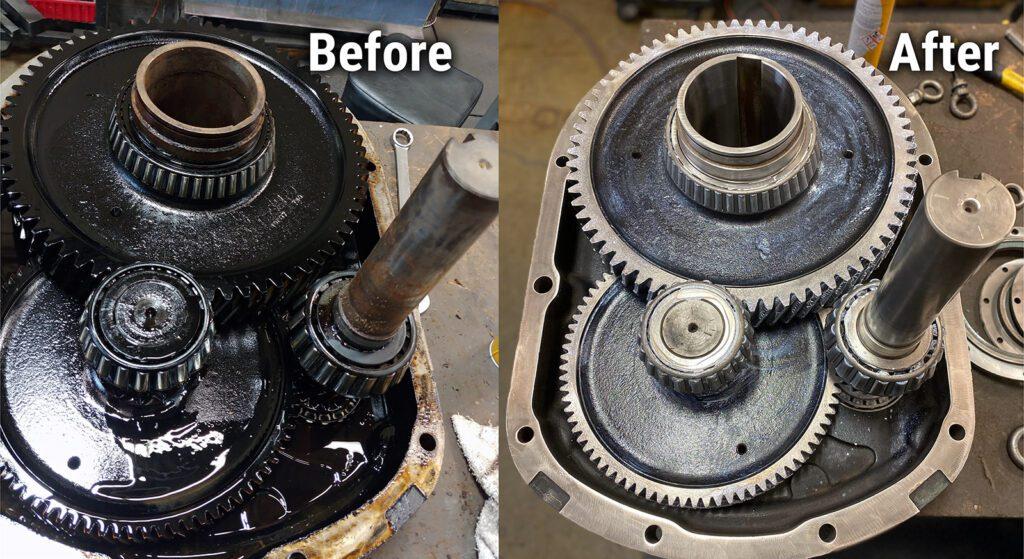

Our Gear Shop at Lawler Gear’s Gearbox Repair Center turns old, worn, broken, and non-functional gear reducers into units that are as good as new.

Our Gear Shop at Lawler Gear’s Gearbox Repair Center turns old, worn, broken, and non-functional gear reducers into units that are as good as new.

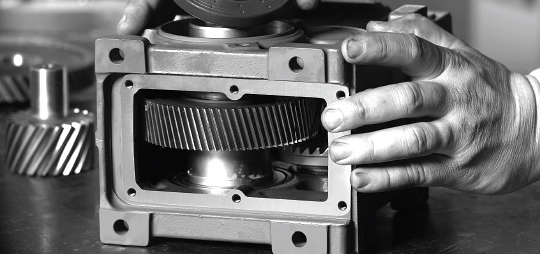

Our Gearing Inspection & Repair Division technicians disassemble the old box completely, determine which parts and pieces need to be replaced, estimate both the costs of repair and replacement, and provide this information so that you can decide how to proceed.

The technicians also examine the old unit to determine the cause of its failure, which may prevent future recurrences of the same problem. Lawler Gear will obtain any needed new parts and clean the old units inside and out. Lawler Gear then reassembles, lubricates, tests the boxes, and paints the casings. If needed, we can also replace sprockets, couplings, sheaves, and motors.

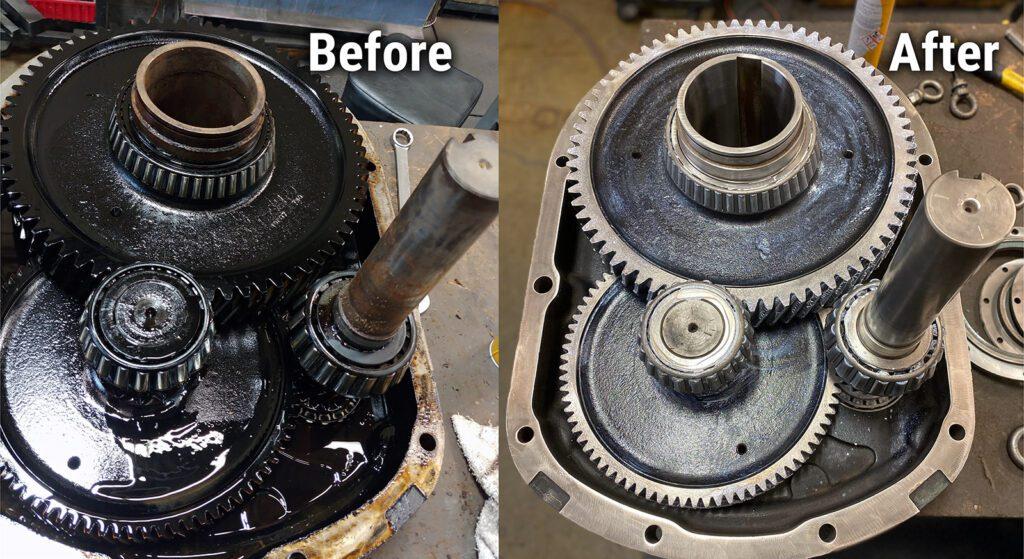

Gearbox Repair and Rebuild Services

- Component inspection and troubleshooting, teardown and rebuild, shaft accessory removal/replacement, waste oil disposal, presswork, etc.

Predictive and Preventative Maintenance

- Avoid catastrophic failure and costly downtime through regular maintenance.

Service on All Makes and Models

- Alling-Landers, Baldor, Bison, Bonfiglioli Riduttori, Boston, Browning, Cleveland Gear, Cone Drive, Curtis, Dalton, Diequa Corp, Dodge, Doris, Durst, Electr Gear, Flender, Falk, Foote Jones, Grove, Hansen, Horsburg & Scott, Hub City, IPTS, Leeson, Lenze, Lufkin, Master PT, Morse, Motovario, Nord, Nutall, Ohio Gear, Onvio, Peerless-Winsmith, Philadelphia, Rexnord, Rossi, SEW, Shimpo, Siemens, Sterling Stober, Sumitomo, Superior, Von Ruden, and many more.

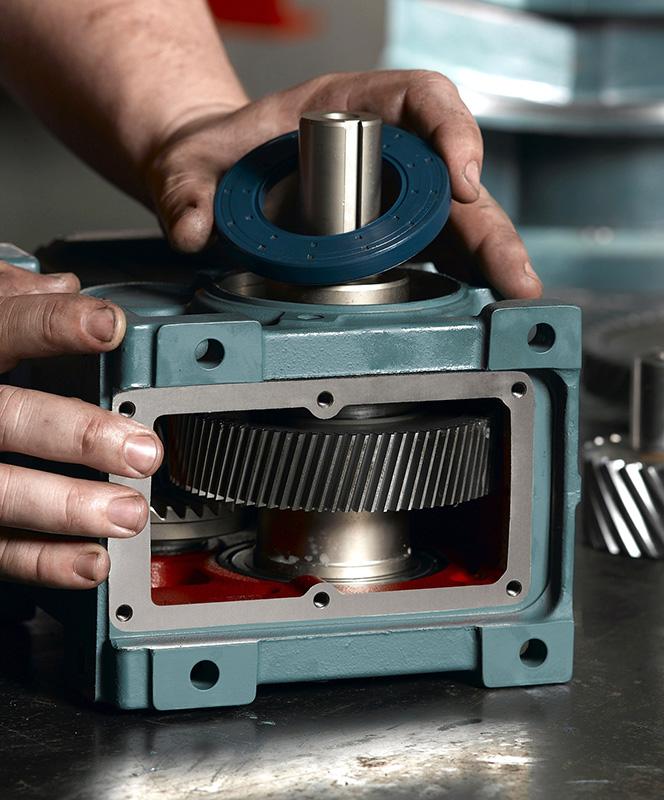

QUANTIS/IBT Build Program

IBT and Lawler Gear are authorized assemblers of Dodge Quantis In-Line Helical (ILH) and Right Angle Helical (RHB) reducers in four sizes (38 through 88). ILH input configurations include c-face clamp collar motor adapters for input motor flexibility and solid input shafts for v-belt mounting. RHB input configuration includes c-face clamp collar, and output configurations of solid, straight hollow, and taper bushed shafts. Quick delivery options include 24 or 48 hour deliveries as required. Our dedicated support staff is experienced and knowledgeable about the QUANTIS ILH & RHB products.

- Modular designed gear drives are engineered for flexibility, greater torque density in a compact housing configuration, and increased horsepower capability from 1/4 hp to 75 hp.

- Single helical design gearing is ground to provide an ellipsoid tooth form that eliminates tooth wear, and assures meshing in the strongest tooth area. This results in reduced noise and power losses.

- All gears are case carburized to ensure high surface durability and resilient tooth core for greater impact resistance and longer service life to reduce unscheduled downtime. Gears are designed to meet DIN-7 standards – approximately equivalent to AGMA 10 – 11. ILH reducers are 98.5% efficient per stage of reduction. RHB reducers are 95% efficient per stage of reduction.

- Reducers, gears and bearings are splash lubricated with ISO VG220 mineral oil and are filled prior to shipment. Nitrile rubber input and output lip seals produce less drag and heat, and promote longer life.

- Greater output torque ratings, increased horsepower ratings and expanded ratio range may allow downsizing from existing units, resulting in reduced production costs while achieving exact output speeds.

Our Gearing Inspection & Repair Division is prepared to take on any gearbox repair challenge. Our team of specialists is capable of servicing almost any make and model used in today’s industry, either up to a size TXT 10 or TA1050 Dodge, or any other comparable, competitive brand with a max weight close to 2000 lbs. We also build size 38, 48, 68 and 88 Dodge Quantis units, both inline and right angle, in only double or triple reduction. Our limitations are with any food grade, painted or stainless Quantis Boxes.

About IBT’s Gearing Inspection & Repair Division

IBT’s gear shop, headquartered at Lawler Gear’s Repair Center, offers comprehensive gearbox repair, replacement, predictive maintenance, and design services. Our team can even examine your old unit to help determine the cause of failure, in order to prevent the same problem from happening again in the future. We service a wide variety of makes and models.

Need help from our Gearing Inspection & Repair Division? Contact us today and we’ll connect you with our team of experts who are standing by to provide you with the best solution for your application.

Want to Learn More About Lawler Gear?

Check out their website to learn more about their services and history.