Our Specialty Machining Services division is made possible through our partnership with UltraTech Aerospace, a market leader in providing OEM aerospace products and services to the commercial and defense industries. UltraTech is located in Kansas City, KS, not far from IBT’s headquarters in Merriam, KS. Serving as the perfect partner for our customers, UltraTech is dedicated to continually refining their manufactured and machined components, tool-kitting, assemblies, complex milling, and distribution of aerospace bearings and fittings.

Take a Closer Look at Our Specialty Machining Services

Aerospace Assembly Division

Providing precision in all aspects of fabrication, installation, and repairs for the most advanced aerospace platforms in today’s market.

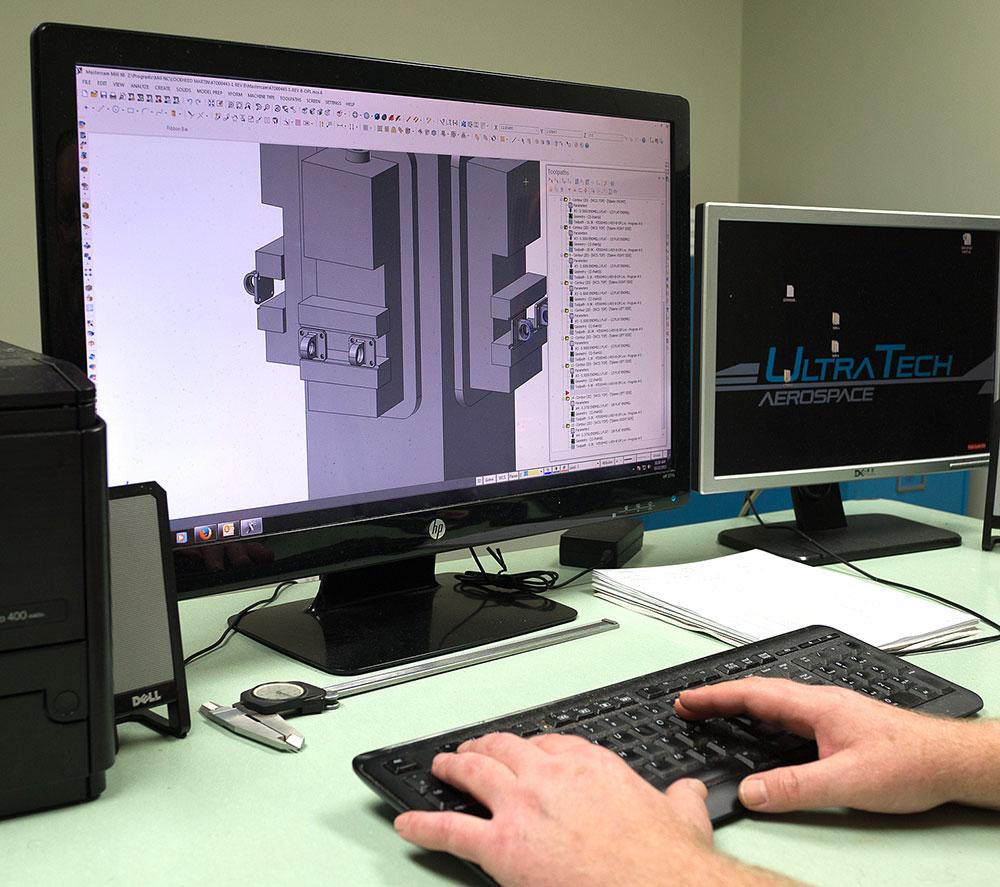

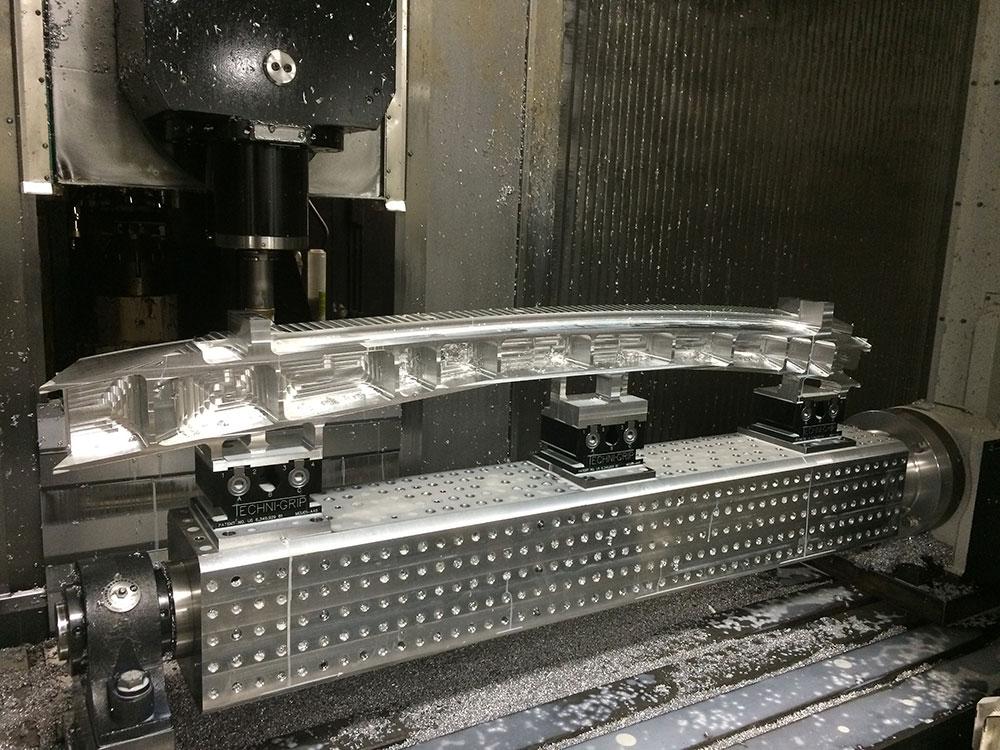

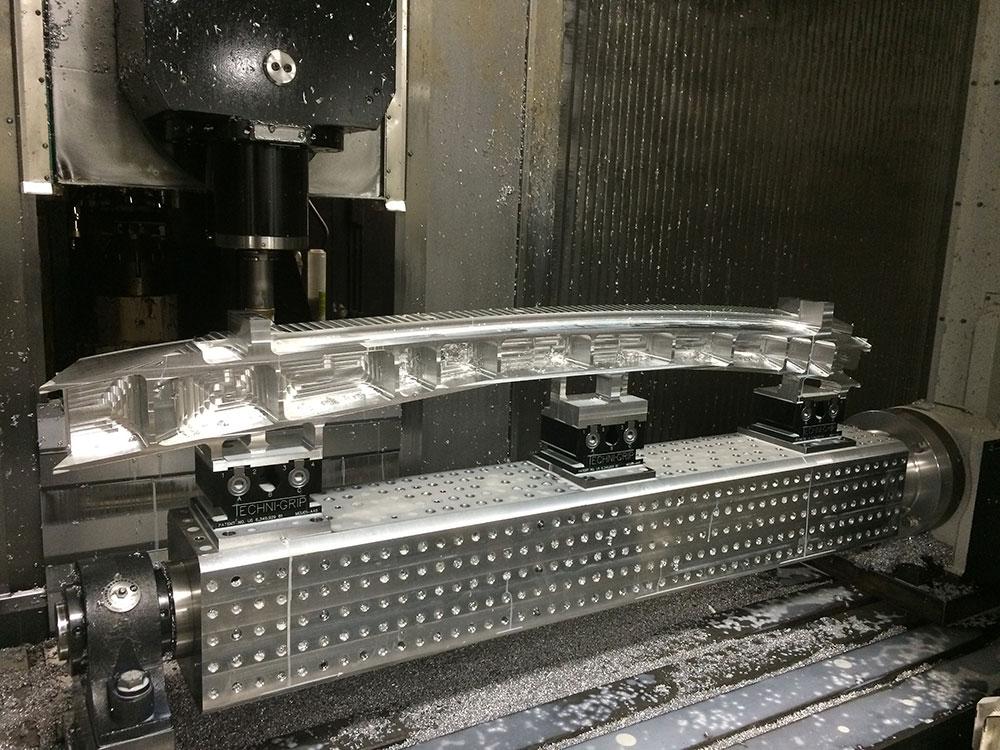

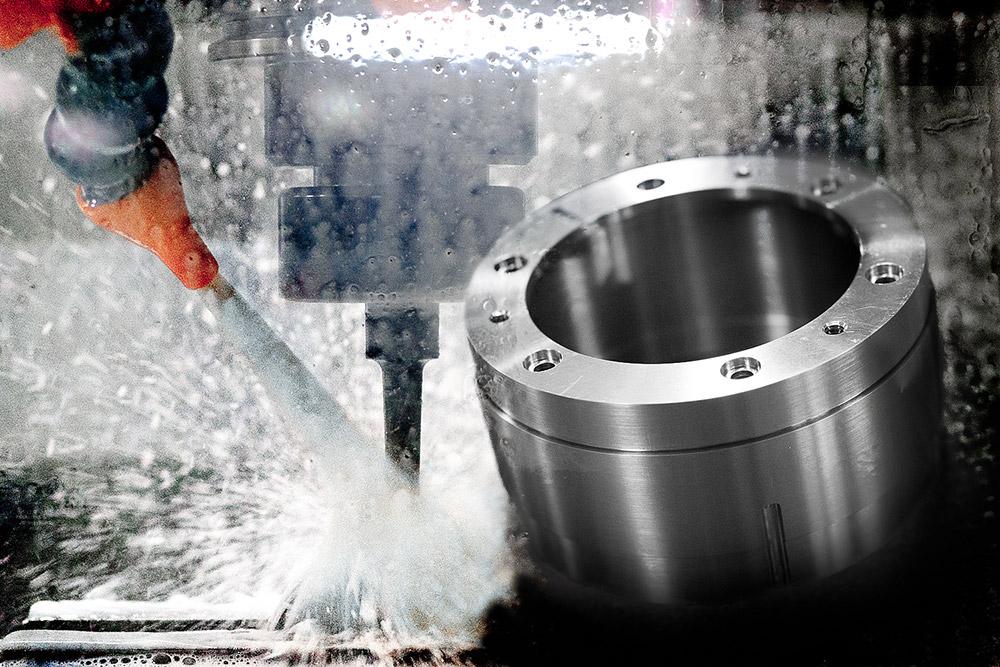

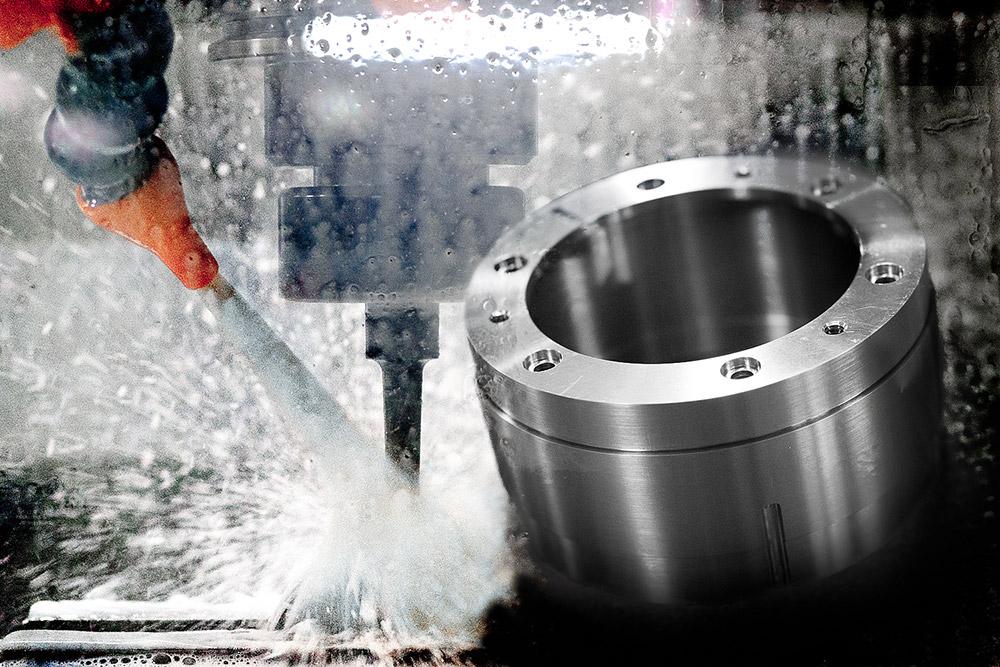

Aerospace Machining Division

Using top-of-the-line computers and mechanically controlled machines to create detailed solutions for unique geometries and parts.

Aerospace Testing & Repairing Division

Ensuring your components hold up to the most stringent requirements and demands with functionality, mechanical, and load testing.

UltraTech’s Certifications & Affiliations

At UltraTech, quality is integral to each and every part of the product cycle, backed by industry certifications and affiliations — ensuring uncompromising standards and requirements are met for each project.

- AS9100 Rev D

- ISO9001:2015

- PQR 1050

- SBA-Certified

- KC Chapter of NTMA

- KC Machining Network

If you would like additional information about our Aerospace Machining Division services, or are interested in placing an order, contact us today.

To learn more about UltraTech’s capabilities, visit their website.