Although motors and belts often steal the spotlight in industrial operations, there are many smaller, equally essential parts working behind the scenes to ensure precision performance and smooth operation—rod ends, among them.

What Are Industrial Rod Ends?

What Are Industrial Rod Ends?

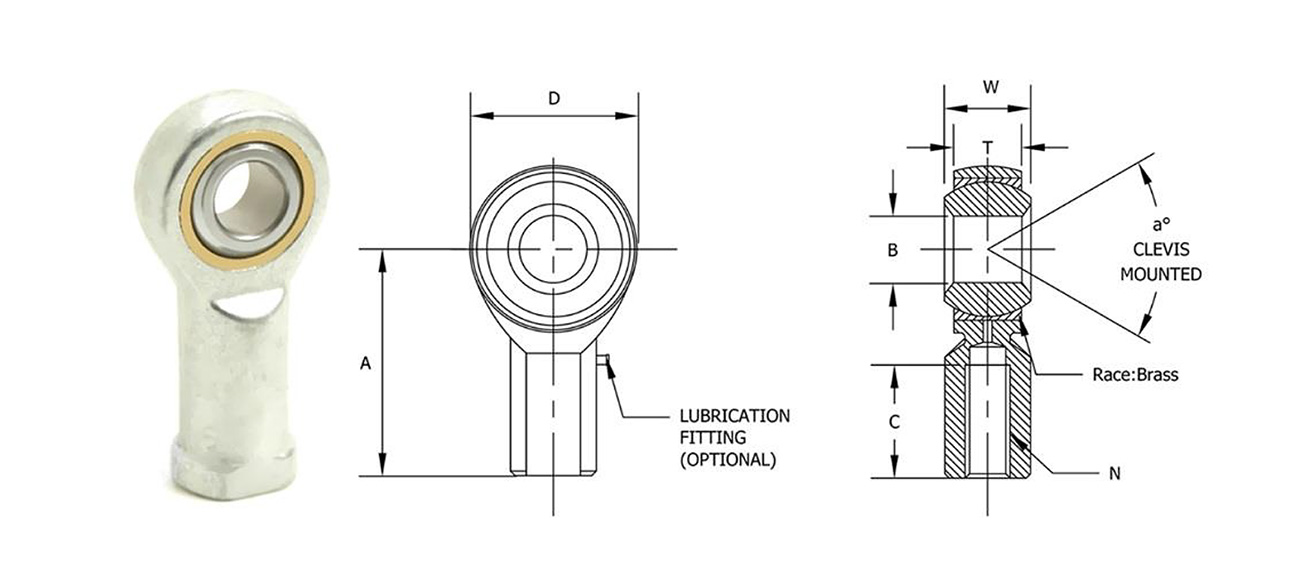

Rod ends consist of a spherically shaped inner ring and a cylindrical bore for mounting on the ends of cylinders, linkages, rods, and shafts. Similar to plain spherical bearings, rod ends are designed for linkage applications to accommodate significant misalignment.

The purpose of a rod end is to allow for some rotational freedom on three axes but keep a fixed point of contact between two different parts.

Industrial rod ends may be classified by either male or female. This classification is determined by the threading. Rod ends with external threading are male, while rod ends with internal threading are female. Because of the difference between male and female industrial rod ends, each are used in their own unique applications.

What Are Industrial Rod Ends Used For?

The applications of rod ends include precision machinery, industrial equipment, lawn and garden equipment, farm equipment, aircraft, truck/bus/off-highway vehicles, and recreational vehicles.

Many may wonder when it makes sense to use a rod end over a spherical bearing, or vice versa. While plain spherical bearings offer greater flexibility in housing and mounting design, the user is responsible for housing design and the cost of housing manufacture. On the other hand, rod ends offer greater mounting convenience and provide a compact, lightweight, economical design alternative to the spherical plain bearing.

Precision Rod Ends vs. Commercial Rod Ends: Which Is Better?

There are four different grades of rod ends—precision, commercial, aircraft, and military. Each come in various sliding layer contact surface combinations to suit their application and environment: steel-on-steel, steel-on-bronze, steel-on-PTFE composite material, steel-on-PTFE fabric, and steel-on-PTFE plastic.

In industrial applications, precision and commercial rod ends are standard.

When Should I Use Precision Rod Ends?

Precision Rod Ends are manufactured to tight tolerances for applications requiring a more precise rod end—for example, a linkage where positioning accuracy is essential. They typically use brass race inserts for lubricity and clearance control, and have end bodies and balls plated for corrosion resistance.

The Tritan precision rod ends HF series three-piece construction provides steel on bronze contact for lubricity, smoother operation, and long dynamic life.

Tritan’s metric rod ends SA(L) SI(L) series are also available where a precision rod end is required in a metric size. The construction offers the added benefit of high strength for high loads, and provides steel-on-steel contact for lubricity, smoother operation, and long dynamic life.

When Should I Use Commercial Rod Ends?

Produced using standard materials and manufacturing methods, commercial rod ends are an economical choice for industrial applications.

Plated for corrosion resistance with a brass race and inserts designed for lubricity and clearance control, these rod ends are preferred for dynamic applications.

Tritan commercial rod ends two-piece, metal-on-metal construction offers the most economical design for a wide range of light to heavy-duty motion transfer applications.

To learn more about how Tritan Rod Ends can increase efficiency in your workplace, Contact your local IBT sales rep today!