Screw Conveying Systems

When a conveyor goes down, IBT has you covered for all your screw conveyor parts and accessories. When you partner with IBT, you’re partnering with the best names in the industry.

Conveyors Inc., Martin & KWS Manufacturing

Screw conveyors are available in sizes ranging from 4″ to 24″ diameter and are compliant with CEMA standards. They are available in a variety of designs, as well as materials, e.g. mild steel, galvanized steel, stainless steel and many other alloys.

Get all screw conveyor and accessory components shipped quickly to you today.

Conveyor Screws

Conveyor Screws operate as a screw helix, mounted on a central pipe or shaft, and rotate within a fixed trough or tube, pushing the material along the bottom and sides. We also offer quick detachable conveyor screws, and both wear and hard surfaced flights for highly abrasive materials, which reduces downtime by making shaft and screw removal much quicker and easier. Select the right conveyor screw for your application and material.

Short pitch ● Stepped pitch ● Tapering flight ● Double flight ● Stepped diameter ● Ribbon flight ● Cone screw ● + More

Shafts and Bolts

Conveyor coupling shafts join individual lengths of conveyor screws. Close couplings adjoin conveyor screws where no hanger is required. In selecting a shaft, ensuring it has the durability and strength to transmit the expected horsepower and torque is key. Shafts are available in drilled and self-locking options to fit your needs. Coupling bolts, also known as gudgeon bolts, connect the shaft to the pipe. They work as a failsafe mechanism to prevent further damage to the system. The most commonly used grades are two and five.

Split Flight Couplings ● End Shaft ● Hanger End Shaft ● No. 1 Drive Shaft ● Special Drive Shaft ● Shaft Seals ● Coupling Shaft

Hangers and Hanger Bearings

Located between screw sections, along the length of a screw conveyor, hangers provide adjustable support, maintain alignment and serve as bearing surfaces within the high-vibration conditions of a screw conveyor system. Hangers and hanger bearings are available in various styles and sizes. Hanger bearings materials include: Wood, UHMW, Bronze, Graphite, Hard Iron.

U-Trough Hanger ● Flared Trough Hangers

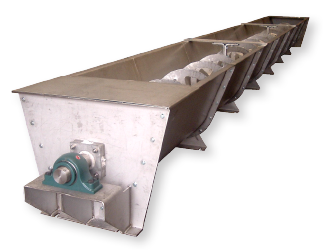

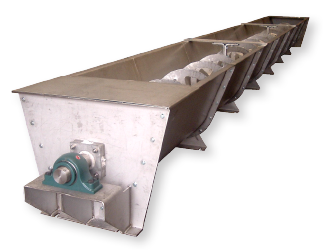

Troughs

Order from a selection of heavy duty troughs, in standard “U”, tubular, rectangular or flared design. Each design is built specifically for the task at hand, to best accommodate the conveyed material━whether that’s draining liquids, handling abrasive materials, protecting against weather or dust, allowing for accessibility for sanitation purposes, insulating hot or cold materials, etc.

Channel Trough ● Drop Bottom Trough ● Jacketed Trough ● Wide Clearance Trough ● Bulk Head Trough ● Expansion Joint Trough ● Perforated Bottom Trough ● Close Clearance Trough ● Dust Seal/Sand Seal Trough ● Channel Side Trough ● High Side Trough ● Jacketed Trough ● Insulated Conveyor Trough

Trough Ends, Seals and End Bearings

Trough Ends support the conveyor screw and trough and hold the rotating screw conveyor in position. Several bearing styles and seals are available to meet your specifications. We can help you with new or replacement trough ends for your system. Select the part you need from a wide variety of trough end types:

Outside ● Outside with Feet ● Inside ● Inside Rectangular ● Single Bearing Pedestal ● Double Bearing Pedestal ● Outside Flared with Feet ● Outside Flared ● Single Bearing Flared Pedestal ● Flared Discharge End ● Outside Discharge End ● Inside Discharge End ● Outside Tubular ● Outside Tubular with Feet

Trough Covers, Clamps and Shrouds

Trough covers keep material inside the trough, as well as protect it from outside elements. They are also a safety measure for workers, preventing them from injuries and keeping them clear of the moving parts inside the conveyor trough.

Standard Cover ● Flanged/Semi-Flanged Cover ● Flat Cover ● Flared Trough Cover ● Hip Roof Cover ● Shroud Cover ● Dome Cover ● Shelf-Type Cover ● Blind Trough Cover ● Plain Cover ● Overflow Cover ● Expanded Metal Cover ● Dust Seal Cover Hinged Cover

Mild steel, stainless steel or zinc-plated clamps are needed to attach covers to troughs, and are best determined based on cover style and accessibility.

Spring Clamps ● Screw Clamps ● Toggles Clamps

Supporting Feet and Saddles

Saddles and feet support, align and secure troughs within screw conveyor systems. Trough feet are used at trough joints, while trough saddles are welded on to support troughs where there is no joint.

Inlets and Discharge Spouts and Gates

Fixed spouts with slide gates allow the distribution of material to be controlled. Standard discharge spouts are available for either conveyor trough or tubular housing in several designs, operated either manually or by remote controls via electric, hydraulic or pneumatic powered gate options.

Angular Discharges ● Standard Spouts ● Round Spouts ● Plain Opening ● Fixed Spout ● Flush End Spout ● Dust Tight Rack ● Pinion Flat Side ● Enclosed Dust-tight or Weather-Proof Spouts

Drive Reducers

With a high-quality drive reducer, you’ll see an increase in cost savings with an extended drive life, along with an increase in thrust load capacity. Other benefits include a high range of AGMA ratios and CEMA standard drive accessories.

Screw Conveyor Drives consist of precision high-quality gearing, rugged and corrosion-resistant cast iron housings, roller bearings that meet/exceed AGMA ratings, precision machined and hardened shafts for maximum load capacity, along with three alternatives in standard adapter seals. Helical Screw Conveyor Drives are composed of fully-enclosed single or double reduction reducers with CEMA drive shafts, mounting adapters, V-drives and motor mount assemblies.

About IBT’S Screw Conveying Systems Experts

As specialists in the conveying systems field, IBT Industrial Solutions’ team understands the importance of good systems application in achieving optimum efficiency. With our years of experience in providing conveying systems and components, you can rely on IBT for the best solution to your problems. contact Jim Boatright, the Conveying Systems Business Group Director at IBT Industrial Solutions.

INTRODUCING AN UPGRADED ONLINE SHOPPING EXPERIENCE – SHOPIBT!

OFFERING YOU THE BEST PRODUCTS IN EVERY CATEGORY

FROM THE BRANDS YOU CAN TRUST

Discover the benefits of the

FREE IBT Advantage Program

Wondering what makes IBT great?

Don’t just take our word for it.

Get in touch for help and information

Our head office address:

9400 W 55th St, Merriam, KS 66203

Call for help:

(913) 428-2858