Bucket Elevators Products

Are you looking to upgrade your bucket elevator or keep your existing system running smoothly? IBT Industrial Solutions is your trusted partner for all your bucket elevator needs. We are a leading distributor and servicer of high-quality bucket elevators and components, renowned for exceptional performance and durability.

Whether you need rubber or PVC belt, punching, or pulleys—from boot to head, we have what you need. We can provide punching and venting patterns of all kinds, for the brands you know like Tapco, Maxi-Lift, and 4B. We also carry UHMW and a variety of urethane liners.

Why Choose IBT for Your Bucket Elevators?

IBT Industrial Solutions has established itself for over 75 years as a reliable partner that takes care of our grain customers. Here are some of the benefits of working with us:

- Increased Efficiency: Our engineers listen to your situation and find the best solution. Our goal is to optimize your material handling, maximizing throughput and productivity.

- Reduced Downtime: By selecting the right equipment for the job, we can offer durable, high-quality products and components that will minimize breakdowns and keep your operations running smoothly.

- Expert Support: Our team of professionals will help you select the right bucket elevator system for the job and ensure optimal performance. We can even help you find the right elevator bucket parts you need to get yours back up and running.

- Complete Solutions: We can offer complete bucket elevator solutions, from replacement parts to belt adjustments to full system designs.

We distribute, design, ship, assemble, repair, and test bucket elevators and their components throughout the Midwest. Find the nearest IBT local branch here.

IBT Offers a Wide Range of Bucket Elevator Products

We are passionate about helping you find the right bucket elevator upgrades, replacement parts, belts, buckets, or replacement elevators you need to get your business back on track and more efficient than ever. Here is a scope of the wide range of bucket elevator products we offer:

Pre-Engineered & Custom Bucket Elevators

IBT partners with high-quality bucket elevator manufacturers like Conveyors Inc., Essmueller, Schlagel, and Universal Industries to ensure that our customers can rely on the performance of their bucket elevators in even the most demanding environments.

If you need a custom-designed bucket elevator, our engineers are happy to assist. We’ll discuss your requirements and specifications, what material you are handling, your challenges, the environment the equipment will be working in, and what level of modular adaptations your bucket elevator will need to handle.

Contact us today to learn more about the pre-engineered and custom bucket elevator solutions we have.

Replacement Elevator Belts

IBT supplies a wide variety of top-quality elevator belts in various materials and sizes to keep your existing elevator running. Our rubber and PVC leg elevator belting is slit to width and punched for your bucket application.

We are especially known for our grain conveyors and elevator belts, and our expertise in selecting the right grain conveyor belt for the job. Besides grain, we also have experience with other free-flowing materials like feed, fertilizer, seed, salt, pellets, and more.

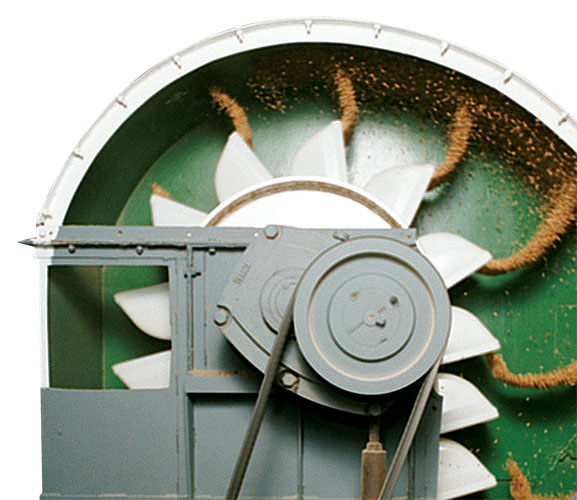

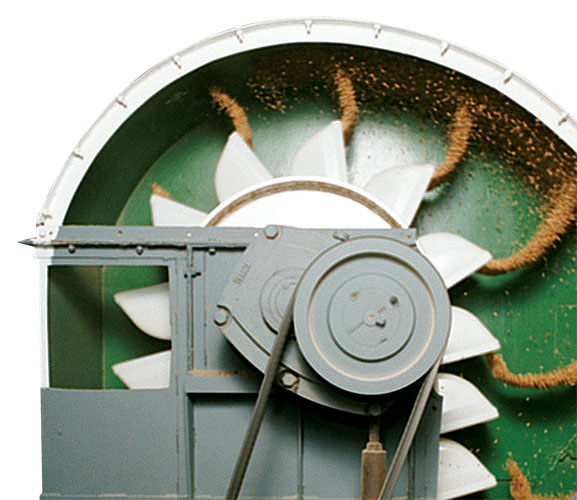

Bucket Elevator Liners

Consider fully lining your elevator head housing and other high-wear areas with easy-to-install urethane liners that offer great abrasion-resistant properties while reducing noise and corrosion. These liners are available in various thicknesses and are commonly stocked in expanded metal-backed (EMB), with select thicknesses available in fabric-backed.

We can advise you on what liners make sense for your budget and application. From a head section with urethane liner and UHMW throat plates, to the boot section with spiral-wrapped wing pulleys, IBT will help you select every piece of lining for your grain bucket elevator based on your specific needs.

Bucket Elevator Hardware

We carry every line of bucket elevator hardware parts, including the carbon steel and stainless bolts, nuts, and washers you need to secure your buckets.

- Bolts: No. 1 Norway Flat/Countersunk Head, Flanged/Pointed Fanged, No. 3 Eclipse Slotted Heads

- Nuts and Spacers: Hex Nut, Square Nut, Large Flange Serrated Lock Nut, Nylon Insert Lock Nut, Poly Spacers

- Washers: Flat Washers, Split Ring Lock Washers, Internal tooth Lock Washers, Fender Washers, Leather Washers, ⅛” and ¼” Thick Neoprene Washers

Buckets for Grain Elevators

We have grain buckets available in all sizes and standard punching and venting patterns. We distribute only the best products available from the top elevator bucket brands, such as Tapco Inc., Maxi-Lift, and 4B.

We supply elevator grain buckets for precise discharge, perfect life, high-speed handling, increased safety, and ease of installation. Low-profile buckets, metallic buckets, and custom venting options are available on request.

Economic, High-Density Polyethylene

- FDA-approved for grain and food products

- -120ºF to +180ºF (210ºF intermittent)

Nylon

- Best for high-heat applications and high-impact materials

- Durable and can withstand tough impact and abrasion

- -60ºF to +300ºF (350ºF intermittent)

Urethane

- Most flexible and highest abrasion-resistance

- Best for heavy, sticky, or sharp materials

- -60ºF to +180ºF (210ºF intermittent)

- FDA-Approved

Tapco®

Polyethylene, Nylon or Urethane Style CC-HD, XD and U-HD

Tapco heavy-duty agricultural buckets handle grains, feeds, fertilizers, seeds, salt, sand, chemicals, and a variety of other free-flowing materials.

Polyethylene elevator buckets are ideal for most applications. Nylon and urethane are recommended for conveying highly abrasive products or when used on extremely high-throughput elevators. Order any of these styles in a “Low Profile” design to increase your grain elevator capacity.

Maxi-Lift®

TIGER-TUFF, TIGER-CC, MAXI-TUFF, CC-MAX, HD-MAX, and HD-STAX

Perfect for a high volume of materials, the high-impact and abrasion-resistant Maxi-Lift elevator buckets are most commonly used in grain, fertilizers, pellets, corn, wheat, soybeans, and other agricultural and light industrial applications.

With thick front lips, corners, and walls, the TIGER-TUFF is the original maximum-duty elevator bucket designed and engineered to increase bucket life, reduce breakage and corrosion, and, ultimately, reduce downtime and maintenance costs. The TIGER-TUFF Low Profile option is reduced in height to allow for more buckets per foot of belt, increasing bucket elevators’ overall capacity.

4B Components Limited

CC-S, JUMBOTM CC-S® HIGH EFFICIENCY™

These top-selling lines of 4B Ultra Heavy Duty Agricultural and Industrial Buckets are available in both Standard and Low Profile-Style Buckets. With a unique Iceberg® Edge front lip and thick walls and corners for longer service life, these buckets are designed to deliver the maximum

possible elevator leg throughput for the lowest cost per ton or bushel.

Molded from virgin HDPE (nylon and urethane also available), they are intended for the most severe applications and highly abrasive materials, such as free-flowing agro-industrial materials (grains, feeds, fertilizers, and pellets).

Bucket Elevator Quote

As specialists in the conveying systems field, IBT Industrial Solutions understands the importance of good system application in achieving optimum efficiency. With our years of experience in providing conveying systems and components, you can rely on IBT for the best solutions.

Request a quote from us today. Whether you need a replacement part, new buckets, or a new bucket elevator system, we have the inventory and expertise of our Conveying Systems Division to ensure an optimized material handling process.

INTRODUCING AN UPGRADED ONLINE SHOPPING EXPERIENCE – SHOPIBT!

OFFERING YOU THE BEST PRODUCTS IN EVERY CATEGORY

FROM THE BRANDS YOU CAN TRUST

Discover the benefits of the

FREE IBT Advantage Program

Wondering what makes IBT great?

Don’t just take our word for it.

Get in touch for help and information

Our head office address:

9400 W 55th St, Merriam, KS 66203

Call for help:

(913) 428-2858