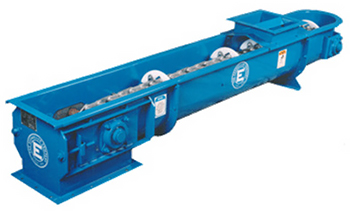

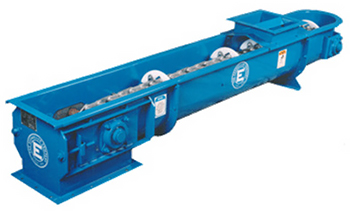

Drag Chain Conveyor Systems: Reliable Parts & Design

At IBT Industrial Solutions, we design and supply custom drag chain conveyor systems to meet your specific needs. We partner with industry leaders like Essmueller, Schlagel, 4B Components, and Tsubaki to ensure you receive top-notch equipment, exceptional service, and reliable performance.

Our team of experts will help you choose the right replacement parts or design a system to efficiently handle your workload and maximize your throughput.

Drag Chain Conveyor Parts

We offer a complete selection of drag chain conveyor replacement parts and components to keep your conveyor running smoothly. Our parts catalog includes:

- Chains: Strong, dependable chains to move material efficiently.

- Paddles/Flights: Durable paddles or flights securely attached to the chain for optimal material handling.

- Sprockets: Toothed wheels that drive the chain, ensuring proper movement of material.

- Troughs: Enclosed channels that guide and contain material during transport.

- Lids: Covers to protect material from contamination.

- Liners: Protective layers that reduce friction and wear, extending conveyor life.

- Materials: Drag chain conveyors can handle different types of materials, like grains, powders, and bulk solids, using components designed for each material’s characteristics.

- Conveyor Chain: The conveyor chain consists of the chain, paddles, and flights, which work together to carry and move the material efficiently.

With our conveyor manufacturing partners, we have on hand or access to any drag chain conveyor component you need.

Drag Chain Conveyor Replacement Flights

Our top two drag chain conveyor replacement flights are:

- UHMW Flights: The preferred choice for the grain industry due to their exceptional strength and wear resistance. The abrasion-resistant material can “flex and give” tremendously with less friction, reducing workloads on drives and motors, and the wear on flights and the trough.

- Food-Grade UHMW Flights: White UHMW flights are ideal for food handling applications and are in compliance with Food Additives Laws and Regulation No. 177.1520. They are an obvious choice with low initial cost and longer operational life.

Count on IBT Industrial Solutions to be the fastest, friendliest, and most reliable drag chain conveyor part supplier!

Benefits of Drag Chain Conveyor Systems

Drag chain conveyor systems have numerous benefits, including:

- Durability: Built to last, drag chain conveyors can handle even the toughest materials.

- Flexibility: They can be configured for various applications and layouts.

- High Capacity: Efficiently transport large volumes of material, boosting productivity.

- Gentle Material Handling: Minimize breakage with minimal metal-to-material contact.

- Energy-Efficiency: Drag chain conveyors require less horsepower compared to screw conveyors.

- Enclosed Design: Eliminate dust and moisture problems for cleaner operation.

- Space-Saving: Lower profile design reduces the footprint required.

- Easy Maintenance: Tail section allows for convenient maintenance access.

- Versatile Discharge: Discharge material at any designated opening.

Drag Chain Conveyor System Customization & Upgrades

We offer a variety of customization options and upgrades to keep your existing drag chain conveyor system updated. Retrofitting your conveyor system will keep it running smoothly and efficiently. These parts can be integrated into an existing system or incorporated into the design of a new system to perfectly suit your specific application.

Here’s a closer look at some of the customization options we offer:

- Thicker UHMW Paddles: Looking to move heavier materials or handle tougher wear and tear? Upgrading to thicker UHMW paddles provides increased durability and can extend the lifespan of your system.

- Split Hubs: Need to make quick and easy chain replacements? Split hubs allow for faster and more convenient chain maintenance, minimizing downtime.

- Roller Chains: For smoother operation and potentially higher speeds, consider upgrading to roller chains. These offer reduced friction compared to standard link chains.

- Trough Liners: Protect your trough from wear and tear with trough liners. These come in various materials to suit the specific materials you’re conveying.

- Bypass Inlets: Need to add a material feed point at a specific location? Bypass inlets allow for easy integration of additional material feeds into your existing system.

- Bend Sections: Need to navigate corners or change directions? Bend sections provide a smooth transition for your chain and material around curves.

- Discharge Gates: Control the flow of material at the end of your conveyor with discharge gates. These offer precise control over the discharge process.

- Safety Monitor Systems: Enhance safety and prevent potential issues with safety monitor systems. These can include features like jam detection or chain breakage alerts.

- Rail Returns: Looking for improved chain guidance and stability? Rail returns provide additional support for the chain, especially on longer conveyor runs.

- Divided Troughs: Need to separate different materials within the same conveyor? Divided troughs allow you to efficiently convey multiple materials side-by-side.

- Flame-Cut Hardened Steel Sprockets: Ensure long-lasting performance and reliable operation with flame-cut hardened steel sprockets. These are built to withstand heavy loads and demanding environments.

By working with our team of experts, you can select the right customization options to optimize your drag chain conveyor system for your specific needs and maximize its performance.

Drag Chain Conveyor Systems Design

Drag chain conveyors are versatile and can be designed in horizontal, inclined, or even L-shaped configurations to meet your specific needs. Their capacities range from 1,000 to 60,000 BPH.

Our Conveying Systems and Services Division will work with you to design a drag chain conveyor system that meets your needs and maximizes your throughput.

We have a variety of options, components, and choices to make the best drag chain conveyor system design:

- Drag Chain Conveyor Types: We offer horizontal and inclined drag chain conveyors, as well as tubular chain conveyor systems.

- Heavy-Duty Construction: Choose from painted steel, galvanized steel, or stainless steel for superior durability in any environment.

- Customizable Options: We offer a wide variety of components are available to tailor your system from beginning to end

Request a quote today to learn more about our drag chain conveyor systems and how we can help you optimize your material handling operations.

INTRODUCING AN UPGRADED ONLINE SHOPPING EXPERIENCE – SHOPIBT!

OFFERING YOU THE BEST PRODUCTS IN EVERY CATEGORY

FROM THE BRANDS YOU CAN TRUST

Discover the benefits of the

FREE IBT Advantage Program

Wondering what makes IBT great?

Don’t just take our word for it.

Get in touch for help and information

Our head office address:

9400 W 55th St, Merriam, KS 66203

Call for help:

(913) 428-2858