Rhino Hyde® polyurethane wear products are manufactured in Minnesota by Tandem Products, Inc. Rhino Hyde® Original Blue, introduced by Cargill in 1965, was the first polyurethane wear liner developed for exclusive use in the grain industry. Over the years, Rhino Hyde® has become a leading abrasion resistant polyurethane liner in multiple industries.

Rhino Hyde® products are highly recommended for the bulk handling of almost any abrasive material, and are put to the test daily in the ever-demanding grain, aggregate, concrete, and mining industries.

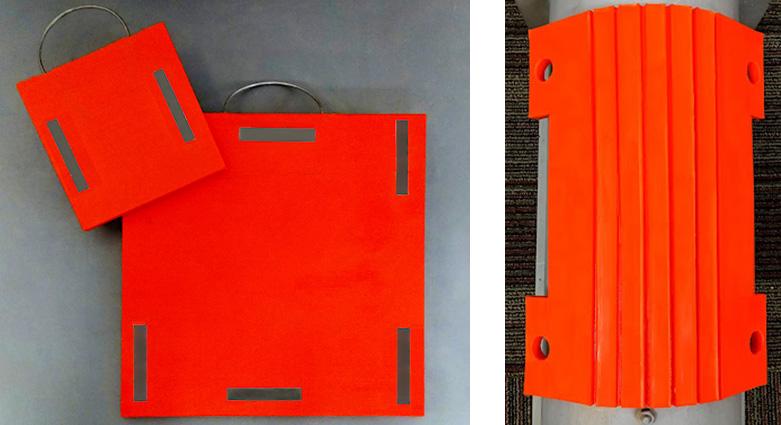

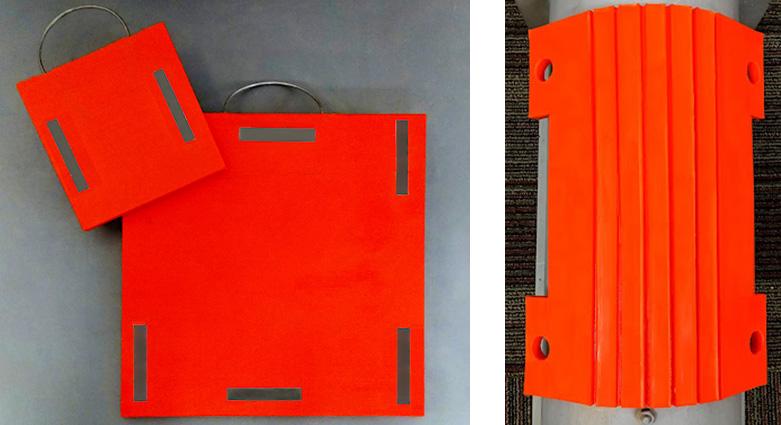

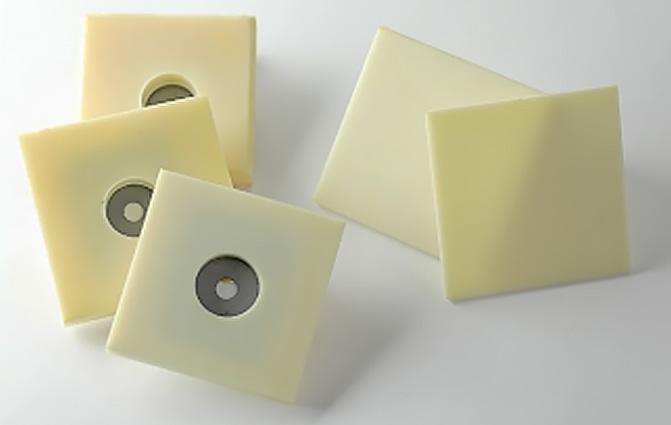

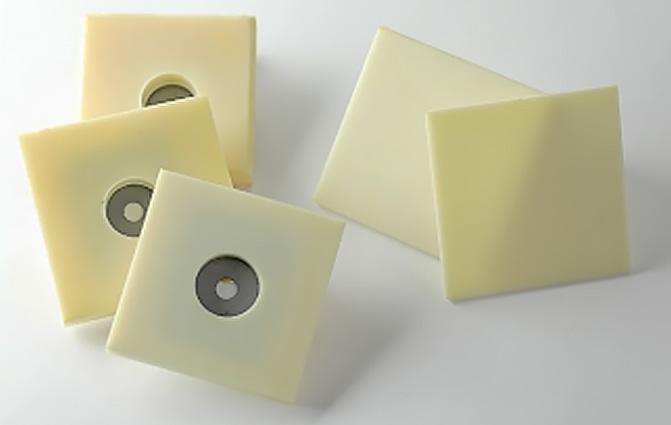

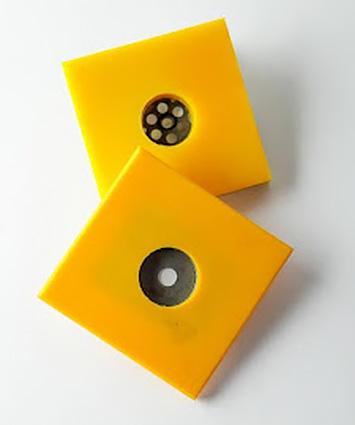

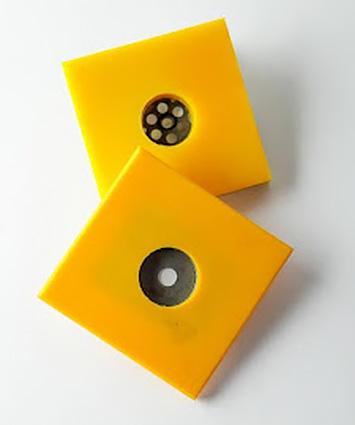

Quickly and easily repair holes worn in flat or curved metal surfaces. Magnets stay secure regardless of climate and withstand vibration and impact.

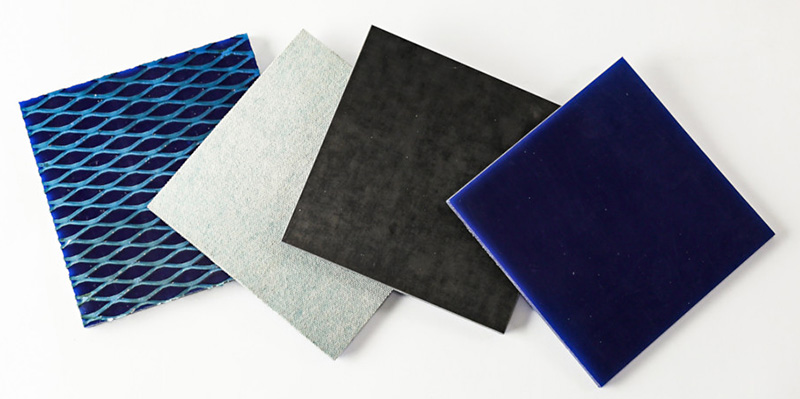

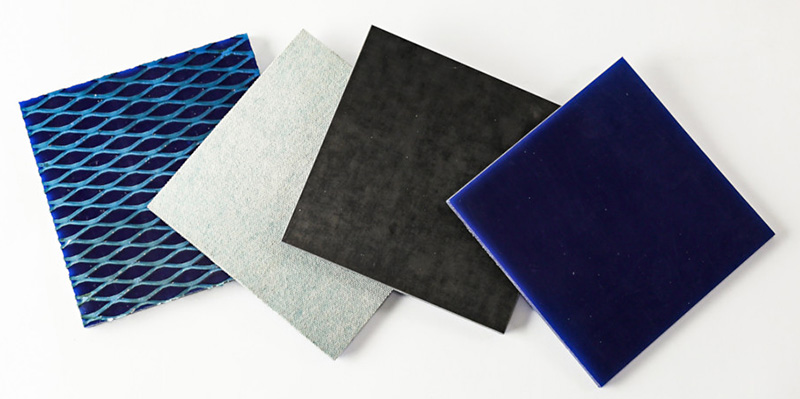

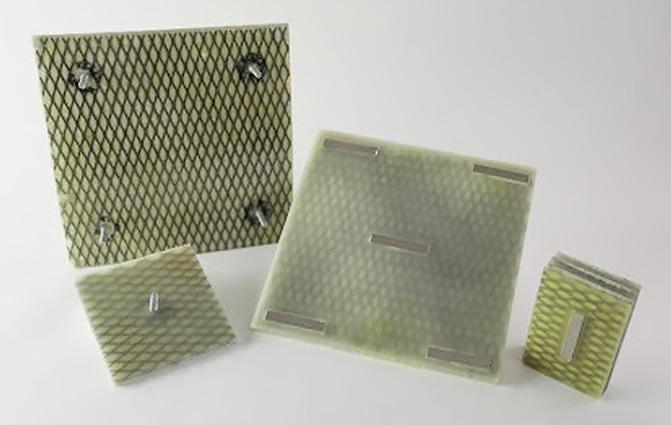

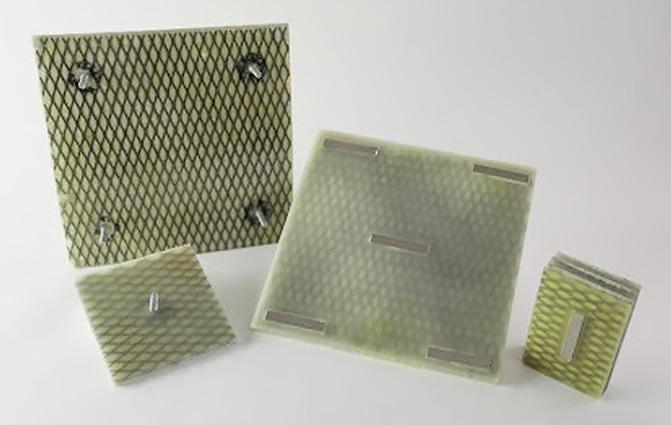

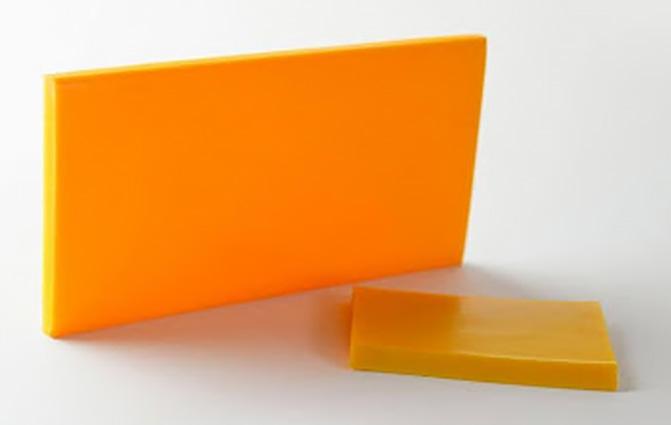

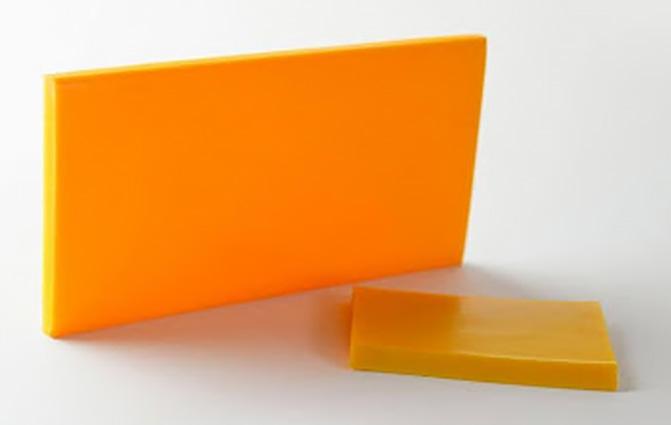

A superior polyurethane formulation with a smooth, slippery that reduces or eliminates material build up and flow issues. Available in 4’ x 8’ sheets or custom sizes in multiple thicknesses. Easy to install with bolts or welds.

A custom blend of urethane polymers and ceramics for use in high impact or wear areas. Will not crack, chip or pop out. Available in custom sizes in multiple thicknesses. Easy installation with bolts or magnets.

Belt Skirting reduces material spillage and helps control dust. Belt Wipers clean and remove heavier, larger materials without excessive belt wear. Available in multiple thicknesses, widths, and lengths.

Used throughout the concrete and aggregate industries to line chutes, spouts, drums, hoppers, etc. Weldable liners reduce noise and material sticking and provide protection for the underlying steel surface. Available in sheets or custom sizes in multiple thicknesses.

To learn more about all of our products, please visit us online: www.rhinohydeproducts.com

Keep up to date on product news and latest offers.

Copyright © 2024 All rights reserved by IBT Industrial Solutions