Sprockets are essential components of many industrial systems. Sometimes known as sprocket wheels, sprockets rotate while engaging with a belt or chain. Notches in the sprocket “catch” with grooved teeth, which allows them to rotate smoothly when they’re in top working order.

The most commonly recognized sprocket is on a standard bicycle, where the sprocket engages with a chain that then transfers the power to the wheels.

It is important to note that while they are often confused, sprockets are not the same thing as gears. This is because of the difference in the transfer of energy. Gears press directly against each other, while a sprocket engages with a chain or belt.

However, like any kind of wearable part, sprockets can develop issues that require attention and repair, and the last thing you want is downtime. If your sprockets are giving you headaches, read on for tips and tricks to ensure your systems keep running efficiently.

Wear and Tear

Sprockets can wear down naturally over time with repeated use and engagement. This can lead to dulled or broken teeth. While normal wear and tear is expected, if left untreated, system failure can occur.

Solutions:

- Regular inspections can help detect wear before it becomes a problem. A general rule of thumb is performing routine maintenance and inspection 24 hours after installation, then at 100 hours, 500 hours, and each subsequent 1,000 hours.

- You may discover a chain that needs replacing during your evaluation. If so, remember to always replace your sprocket when you replace your chain.

- If you find a sprocket damaged by wear and tear, select an appropriate replacement.

- Split sprocket designs can help make regular replacements quicker and easier. Martin Sprocket offers a variety of split sprockets and bushings that can reduce the effort and time required for routine maintenance.

IBT is proud to be a Martin distributor. An example of an available product is the Martin Sprocket Accu-Torch steel sprocket. It is available for virtually all engineering class chains, in style A, B, and C, and can be ordered as split with welded or detachable hubs.

Corrosion and Moisture

The most common cause of corrosion and rust on sprockets is exposure. Whether that’s exposure to moisture or specific chemicals, these environmental factors can do a number on your equipment.

For example, humid environments and salt exposure can combine with abrasive contaminants such as dust and dirt. These may accumulate on the sprocket itself, degrade sprocket quality, and contribute to rust formation.

Solutions:

- Ensure that your sprockets are stored in proper conditions before installing, and protect them from environmental factors when in use.

- Conduct regular inspections and cleanings to avoid the accumulation of particles on the sprockets.

- Consider filtration systems that may remove contaminants, which may prevent them from interfering with your sprocket in the first place.

Operational Stress

Operational stress is also a factor. Sprockets under heavy load, vibration or stress are more likely to experience surface wear, which can degrade coatings and expose metal to corrosion. The overall quality and design of your sprocket makes a difference as well.

Solutions:

- Be sure to select a sprocket with the correct finish and specifications for your application to avoid premature replacements and maintenance needs.

- Not sure which sprocket is the right choice? As a Martin distributor, IBT Industrial Solutions can help you make the right selection for your application. Reach out to us here.

Insufficient Lubrication

Inadequate lubrication of your sprockets can lead to increased friction, and by extension, heat. This breaks down the sprocket over time and can even cause catastrophic failures!

Solutions:

- Always ensure your sprockets are adequately lubricated. If you aren’t sure what the correct lubrication is, refer to your manufacturer’s guidelines.

- Conduct regular maintenance and inspections to confirm proper lubrication.

Tension Problems

Incorrect tensioning is not only hard on your sprockets, but also on your chain or belt. Slippage or worse can occur. Additionally, chain and belt elongation is common as they will lengthen with use. Over time, this will wear down your sprocket teeth, and affect tension throughout your systems.

Solutions:

- Refer to your manufacturer’s equipment manual for the recommended tension values. Once the proper tension has been determined, inspect your sprockets for normal wear and tear. Sprockets with excessive wear and tear should be replaced before adjusting tension.

- Whether you use a wrench, spanner, tension gauge, or another kind of belt tensioner, our Belt Tensioning Guide is key for step by step instructions on how to adjust tension appropriately.

- Once you have readjusted tension, do a test run of your system. Listen and look for any unusual changes after re-tensioning.

- Conduct regular inspections to ensure your chain or belt tension is correct.

Misalignment

Is your chain tracking incorrectly? Check your alignment. A small misalignment can cause big problems, causing uneven wear, sprocket runout, or worse!

Solutions:

- Ensure you have the correct sizing for your sprocket by referring to your manufacturer’s guidelines.

- No manufacturer’s guidelines? You can also give us a call at 913-428-2858, and we’d be happy to see how we can help.

- Inspect your sprocket positioning and system alignment, and check regularly to ensure the sprocket is fitted tightly against the shaft.

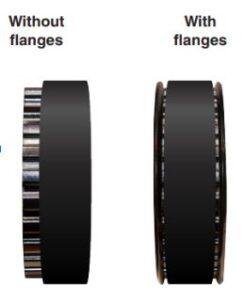

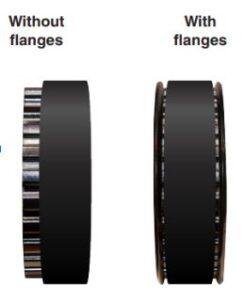

- Consider synchronous sprockets from Martin Sprocket. Synchronous sprockets can provide many benefits, such as increased and more accurate tooth engagement. Flanges on synchronous sprockets run parallel to the belt, acting as a guide on either side, and reducing the chance of belt slippage and misalignment.

Martin Sprocket can also design and deliver sprockets of all kinds when you need them, for a variety of applications. A custom design could be the key to increasing your efficiency. Learn more about their custom sprocket capabilities here.

In conclusion, if you are vigilant about inspecting for wear and tear, reducing and/or avoiding environmental factors that create corrosion, and ensuring sufficient lubrication and tension, your sprocket problems should be a thing of the past.

If you’re still having sprocket issues– or just want to talk sprockets!– our team of seasoned experts in our Power Transmission group would be happy to help. IBT is a Martin distributor, and we can assist you in replacing your existing sprocket, or identify a better solution for the future. Contact us to experience our high quality customer service, and to learn more about how we can solve your sprocket problems.