In the world of industrial automation and manufacturing, pneumatic systems play a crucial role in powering various applications. Pneumatic systems utilize compressed air to transmit and control energy.

In this comprehensive pneumatic systems guide, we will delve into what it is, how it functions, the key components of pneumatic systems, its wide-ranging industrial applications, and compare the differences between pneumatic and hydraulic systems.

What Is Pneumatics?

Pneumatics is a branch of engineering that deals with the study and application of pressurized air to perform mechanical work. It is derived from the Greek word “pneuma,” which means “air” or “breath.” Pneumatic systems are widely used in various industries due to their efficiency, cost-effectiveness, and versatility.

How Pneumatic Systems Work

Pneumatic systems use compressed air, typically generated by an air compressor, to transfer and control energy. A basic pneumatic system follows these steps:

- Compressed Air Generation: The process starts with an air compressor that intakes atmospheric air and compresses it to a higher pressure. Compressed air is stored in tanks or reservoirs to ensure a steady supply.

- Air Distribution: Once compressed, the air is distributed through a network of pipes and hoses to various pneumatic components and devices.

- Control Valve Activation: Pneumatic systems rely on control valves to regulate the flow of compressed air. These valves can be manual, solenoid-operated, or computer-controlled, depending on the application’s requirements.

- Actuation of Pneumatic Components: The compressed air is directed to pneumatic actuators, which can take the form of cylinders or rotary motors. When air is applied to an actuator, it creates motion or force, performing the desired mechanical work.

- Exhaust: After performing the work, the exhaust air is released into the atmosphere, and the cycle repeats as needed.

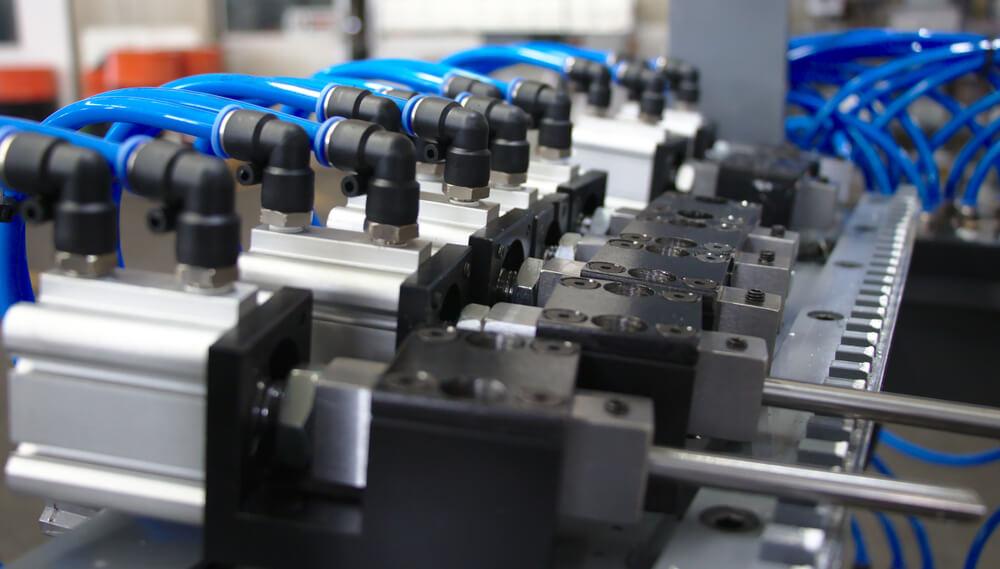

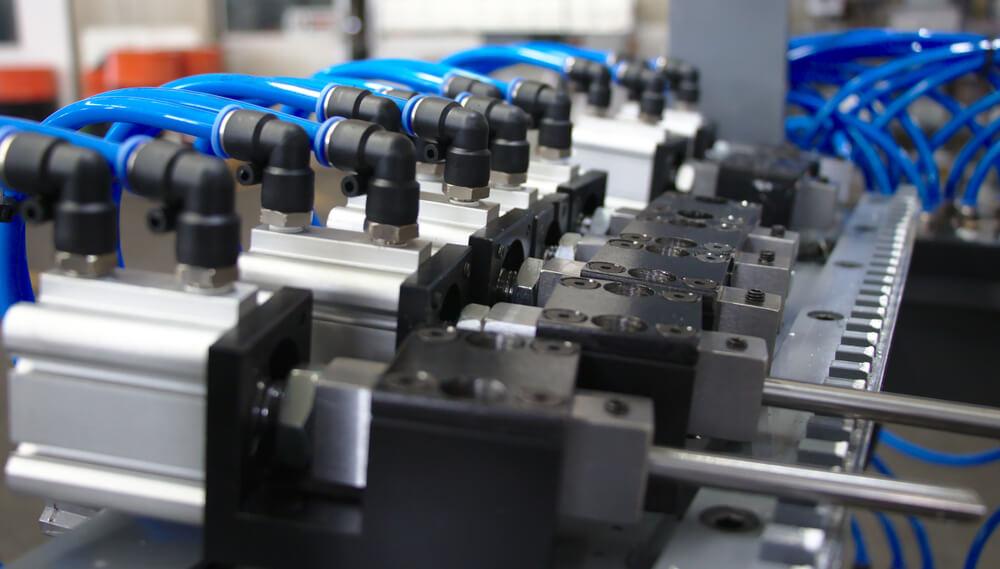

Common Parts of Pneumatic Systems

Pneumatic systems consist of several key components, each serving a specific function in the system’s operation. Common pneumatic system components include:

- Compressor: The air compressor is the heart of a pneumatic system, responsible for generating and maintaining compressed air at the required pressure levels.

- Reservoir or Air Receiver: Compressed air is stored in a reservoir or air receiver, ensuring a stable supply and reducing the load on the compressor.

- Control Valves: Control valves, such as directional control valves and pressure regulators, manage the flow and pressure of compressed air to pneumatic actuators.

- Pneumatic Actuators: Actuators are devices that convert the energy from compressed air into mechanical motion. Pneumatic cylinders and pneumatic motors are common types of actuators.

- Tubing, Pipes, and Hoses: A network of tubing, pipes, and industrial hoses are used to transport compressed air from the source (compressor and reservoir) to various components and actuators.

- Filters and Lubricators: Filters remove contaminants from the compressed air, ensuring clean and dry air for the system. Lubricators provide necessary lubrication to pneumatic components to reduce wear and friction.

- Pressure Gauges: Pressure gauges help monitor and control the pressure levels within the pneumatic system, ensuring safe and efficient operation.

Typical Applications for Pneumatic Systems in Industrial Settings

Pneumatic systems have extensive applications in various industrial and factory settings due to their reliability and adaptability. Some typical applications include:

- Manufacturing and Assembly Lines: Pneumatics power conveyor systems, robotic arms, and grippers that are used in manufacturing and assembly processes. They provide precise control and high-speed operation.

- Packaging and Material Handling: Pneumatic systems are integral in packaging machinery, enabling tasks such as sealing, labeling, and sorting. They are also used in material handling equipment for lifting, pushing, and gripping items.

- Automotive Industry: Pneumatic tools, such as impact wrenches and air-powered drills, are widely used in automotive assembly plants for efficient and high-torque fastening.

- Food and Beverage Production: Pneumatic systems are employed in food processing and packaging, ensuring hygienic and contamination-free operation. They handle tasks like filling, capping, and sorting.

- Textile and Printing: Pneumatics are used in textile machinery for weaving, spinning, and dyeing processes. In printing, pneumatic systems control the movement of paper and printing heads.

- Agriculture: Pneumatic systems are used in farming equipment, such as seed planters and harvesters, to automate various agricultural tasks.

Comparing Pneumatic vs. Hydraulic Systems

Both pneumatic and hydraulic systems are widely utilized in industrial applications, but they differ in their working fluids, characteristics, and suitable applications. Let’s compare the pneumatic systems versus hydraulic systems:

Working Fluid:

- Pneumatic Systems: Use compressed air as the working fluid. Air is readily available and does not pose environmental hazards, making it ideal for clean applications.

- Hydraulic Systems: Use hydraulic oil as the working fluid. Hydraulic oil has better lubricating properties but requires careful hydraulic system maintenance. They may be less suitable for environments where oil contamination is a concern, but environmentally friendly fluid solutions may be available.

Operating Pressure:

- Pneumatic Systems: Operate at lower pressures compared to hydraulic systems. Typical pneumatic pressures range from 80 to 100 psi (pounds per square inch).

- Hydraulic Systems: Operate at higher pressures, often exceeding 1,000 psi. This allows hydraulic systems to generate more force and work with heavy loads.

Speed and Precision:

- Pneumatic Systems: Offer high-speed operation and excellent response times, making them suitable for applications requiring rapid movements and quick response.

- Hydraulic Systems: Provide precise control and high force, making them ideal for applications that require heavy lifting and precise positioning.

Environmental Considerations:

- Pneumatic Systems: Generate minimal heat and noise, are clean and environmentally friendly, and do not require as extensive maintenance.

- Hydraulic Systems: Generate more heat and noise, may pose environmental concerns due to potential oil leaks, and require regular maintenance to prevent fluid contamination.

Cost and Efficiency:

- Pneumatic systems: Generally more cost-effective to install and maintain, often making them a preferred choice for many industrial applications.

- Hydraulic systems: Tend to have higher initial costs, primarily due to the need for hydraulic fluid, but may offer higher efficiency in some heavy-duty applications.

Applications:

- Pneumatic Systems: Excel in applications where cleanliness, speed, and simplicity are essential, such as in the packaging, automotive, and electronics industries.

- Hydraulic Systems: Shine in applications where high force, precise control, and heavy-duty performance are required, such as in construction, mining, and heavy machinery.

Pneumatics is a remarkable technology that harnesses the power of compressed air to drive a wide range of industrial applications. Its simplicity, speed, cleanliness, and cost-effectiveness make it a preferred choice in many industries.

Understanding how pneumatic system components and processes work, as well as their comparison to hydraulic systems, can help businesses make informed decisions when choosing the right system for their specific needs. Whether it’s powering manufacturing equipment or enabling intricate assembly processes, pneumatics continues to shape the landscape of industrial automation.

Contact IBT Industrial Solutions for comprehensive support in the design, maintenance, or installation of your pneumatic system. Our team of seasoned experts in our Fluid Power & Hydraulics Division possess extensive experience in both hydraulic and pneumatic systems, ensuring tailored solutions to meet your specific objectives.

Furthermore, our dedicated hose division stands ready to expertly assemble and install your system, empowering your machinery with the efficiency and precision that pneumatic technology has to offer. Contact us today to request a pneumatic or hydraulic system quote.