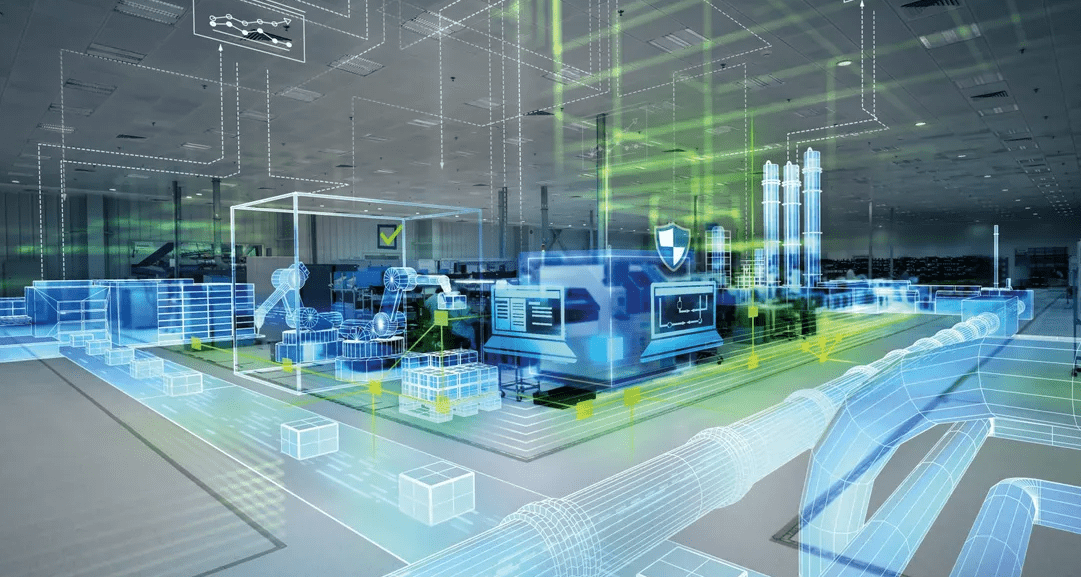

Industrial automation tools have ushered in a new era of efficiency, precision, and innovation across a wide range of industries. These tools enable automated technologies to streamline processes, reduce human intervention, and enhance productivity.

Let’s delve into what industrial automation tools are, why they are essential, and explore various types of these tools, including programmable logic controllers (PLCs), human-machine interface (HMI) systems, robotics, and sensors and vision systems.

What Are Industrial Automation Tools & Why Are They Important?

Industrial automation tools encompass a suite of technologies and systems designed to automate and optimize industrial processes. Industrial automation offers numerous advantages, including:

- Increased Efficiency: Automation tools perform repetitive tasks with consistent precision, reducing the likelihood of errors and the need for manual labor. This efficiency boost translates into higher productivity and reduced operational costs.

- Enhanced Safety: Automation tools can handle dangerous tasks, such as welding or handling hazardous materials, without risking human health. This leads to improved workplace safety.

- Quality Assurance: Tools like sensors and vision systems ensure products meet strict quality standards by identifying defects early in the production process.

- Cost Savings: By minimizing human intervention, automation tools reduce labor costs, energy consumption, and material wastage.

- Real-Time Monitoring: Industrial automation tools provide real-time data and insights into production processes, allowing for quicker decision-making and proactive troubleshooting.

Now, let’s explore some of the most common types of industrial automation tools and control systems and some examples of their capabilities in more detail:

1. Programmable Logic Controllers

Programmable logic controllers (PLCs) are the workhorses of automation in industries like manufacturing, automotive, and food processing. These compact controllers can be programmed to manage a wide array of tasks, from regulating the flow of materials in a chain conveyor belt system to controlling the temperature in an industrial oven.

In automotive manufacturing, for instance, PLCs ensure precise assembly line coordination, leading to improved production rates and reduced errors.

- Industries: Besides manufacturing and automotive, PLCs are vital in industries like food and beverage production, where they control cooking and packaging processes.

- Capabilities: PLCs can manage complex sequences of operations, handle analog and digital inputs/outputs, and respond rapidly to changing conditions. In the food industry, PLCs ensure precise temperature control in ovens and accurate ingredient mixing in production lines.

2. Human-Machine Interface Systems

Human-machine interface (HMI) systems are crucial in industries like pharmaceuticals, packaging, and power generation. These systems provide operators with an intuitive interface to monitor and control machinery. In pharmaceuticals, HMI systems allow operators to adjust the settings of packaging machines easily, ensuring accurate dosing and labeling.

- Industries: The pharmaceutical industry relies on HMI systems to control pharmaceutical packaging machines and ensure that labeling and dosing are accurate.

- Capabilities: HMI systems provide real-time data visualization, enabling operators to monitor processes, adjust parameters, and troubleshoot issues efficiently.

3. Robotics and Robotic Process Automation (RPA)

Industrial robots are prominent in automotive assembly lines, material handling in logistics, and precision tasks in the electronics industry. In logistics, autonomous mobile robots are revolutionizing warehouse operations, efficiently picking and transporting goods to meet growing e-commerce demands.

- Industries: The automotive industry relies on robotics for tasks such as welding, painting, and assembling components, significantly enhancing production efficiency and product quality. Warehouse automation is dominated by pick and place robots to do the heavy lifting and sorting of packages and goods.

- Capabilities: Industrial robots equipped with RPA can execute precise operations such as welding on automobile chassis, ensuring uniformity and structural integrity. These robots can work tirelessly on assembly lines, resulting in increased production rates and improved weld quality, while also reducing the need for manual labor in hazardous environments.

4. Sensors and Vision Systems

Industries such as agriculture, pharmaceuticals, and electronics rely heavily on sensors and vision systems. In agriculture, sensors monitor soil conditions and crop health, enabling precise irrigation and fertilization. Vision systems inspect pharmaceutical products for defects, guaranteeing the highest quality in every batch.

- Industries: Commonly used in agriculture, pharmaceutical, and electronic industries, sensor and vision systems enable quality assurance and identification. In electronics manufacturing, sensors and vision systems inspect printed circuit boards for defects, ensuring product quality.

- Capabilities: These systems can detect variations in color, shape, or size and provide data for process optimization and quality control. They can also monitor soil conditions and plant health, as well as identify invasive weeds, pests, or even various plant diseases.

These industrial automation tools are not just limited to specific industries; they are highly adaptable and can have applications in various sectors. The key is understanding how each tool can be tailored to meet the unique requirements of different industrial processes, ultimately driving efficiency, safety, and quality across the board.

IBT Industrial Solutions understands how to tailor each of the automated industrial tools to meet your specific needs. We are an industrial automation company with engineering experts who are familiar with a wide range of automation systems that can be implemented and customized to improve efficiency, safety, and quality. Contact our automation experts to learn more!