In industrial operations, optimizing efficiency is paramount. Ensuring seamless mechanical power transmission is essential for equipment to operate at peak performance. Speed reducers play a crucial role in achieving this goal. In this article, we’ll take a closer look at Torque-Arm speed reducers, examining their significance and the practical benefits they offer. We’ll also explore the latest generation of TXT, the original Torque-Arm speed reducer, from Dodge® Industrial and how it has evolved over the last 70 years.

What are Torque-Arm Speed Reducers?

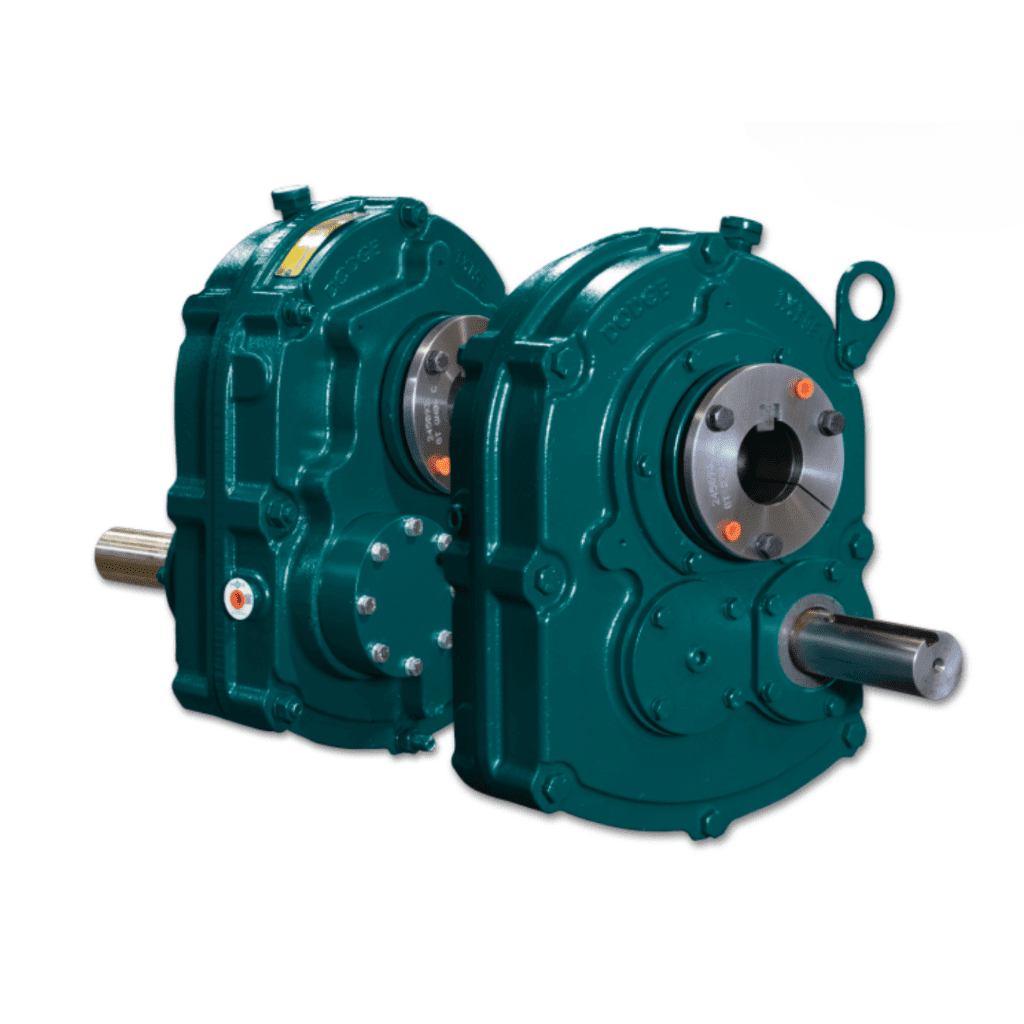

Torque-Arm speed reducers are vital components in industrial equipment and mechanical power transmission systems. These mechanical devices are designed with a singular purpose—to adjust the speed and torque of a rotating input source, such as an electric motor, to meet the specific requirements of a driven component, like a conveyor belt, mixer, or any other industrial equipment.

In essence, they act as the bridge between power sources and the equipment they drive, reducing the high-speed rotation of an input source into a slower, more powerful output. This is particularly important when you have equipment that requires a different speed and torque than what your power source naturally provides.

What sets certain Torque-Arm speed reducers apart is their adaptability and performance. For instance, TXT speed reducers from Dodge, a standout in this product line, are designed to be easily mounted to the driven equipment, typically via a shaft, making installation and integration into existing systems relatively straightforward. The thoughtful Dodge TXT design incorporates lubrication systems to ensure smooth operation and reduce wear and tear over time, delivering a reliable and efficient mechanical power transmission solution for various industrial applications.

Advantages of Torque-Arm Speed Reducers

Improved Efficiency

One of the most significant advantages of Torque-Arm speed reducers is their ability to enhance the efficiency of mechanical power transmission. These reducers are engineered with precision to minimize energy loss during the speed reduction process and contribute to substantial energy savings over time. This translates not only into reduced operating costs but also into a more sustainable and environmentally friendly operation.

The improved efficiency of Torque-Arm speed reducers means that less heat is generated during the power transmission process. This reduction in heat production not only contributes to the longevity of the equipment but also minimizes the need for complex cooling systems, further streamlining operations.

Enhanced Reliability

The reliability of Torque-Arm speed reducers is another critical feature for streamlining operations. They are designed to provide consistent and trouble-free operation, significantly reducing the risk of unexpected downtime due to mechanical failures.

Their ability to operate smoothly and consistently over extended periods ensures equipment operates at its optimal level and reduces the wear and tear on critical components. This extends the product life and significantly lowers maintenance and replacement costs. Operations benefit from increased productivity and reduced overheads, contributing to a healthier bottom line.

Torque Multiplication

At the heart of Torque-Arm speed reducers lies the concept of torque multiplication. This is a pivotal aspect of power transmission, particularly in situations where equipment needs to handle heavy loads or operate under challenging conditions. Torque-Arm speed reducers excel in this regard, effectively multiplying the torque output while simultaneously decreasing rotational speed.

By adjusting torque and speed, these reducers empower industrial equipment to tackle demanding tasks with ease. Whether it’s driving conveyor belts, hoisting heavy materials, or powering industrial mixers, Torque-Arm speed reducers ensure that equipment operates reliably and efficiently, even under substantial stress.

The Legacy of Dodge TXT

Now that we’ve explored the advantages of Torque-Arm speed reducers in greater detail, let’s delve into the illustrious history of Dodge innovation.

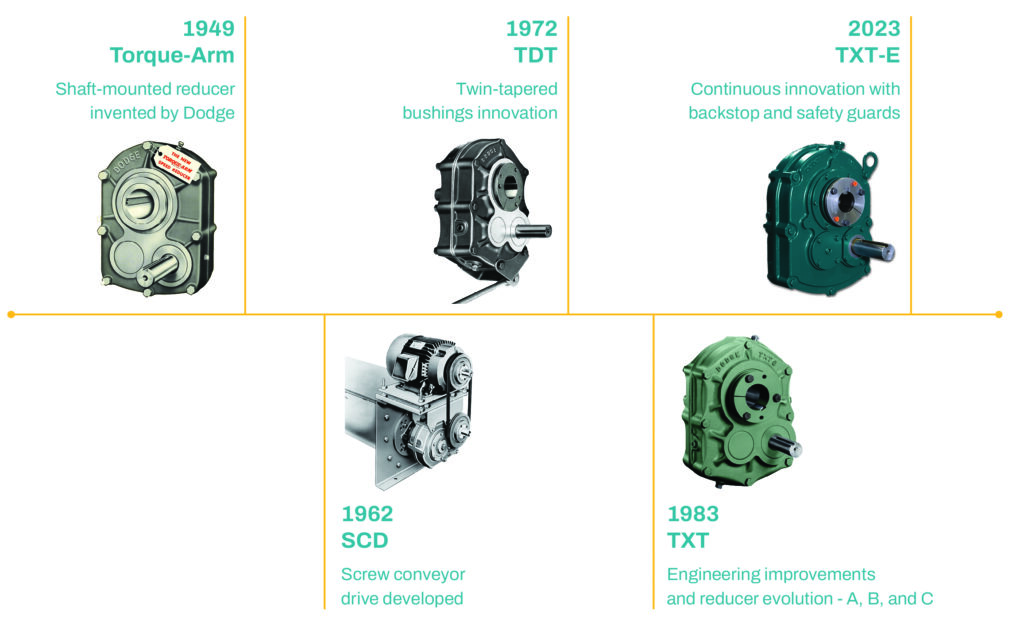

Innovation Begins: The Original Torque-Arm (1949)

In 1949, Dodge invented the concept of shaft mounting a reducer with the introduction of the original Torque-Arm, now known as TXT. This innovation revolutionized industrial equipment by significantly reducing the number of components needed to connect driven equipment, simplifying installations, and minimizing potential points of failure.

A Game-Changing Invention: Twin-Tapered Bushings (1972)

Fast forward to 1972, and Dodge once again reshaped the industrial landscape with the introduction of twin-tapered bushings in their TXT speed reducers. This ingenious innovation streamlined installation and removal processes and significantly reduced common issues such as shaft-to-reducer fretting, eccentricity, and wobble.

The Newest Generation of TXT Speed Reducers (2023)

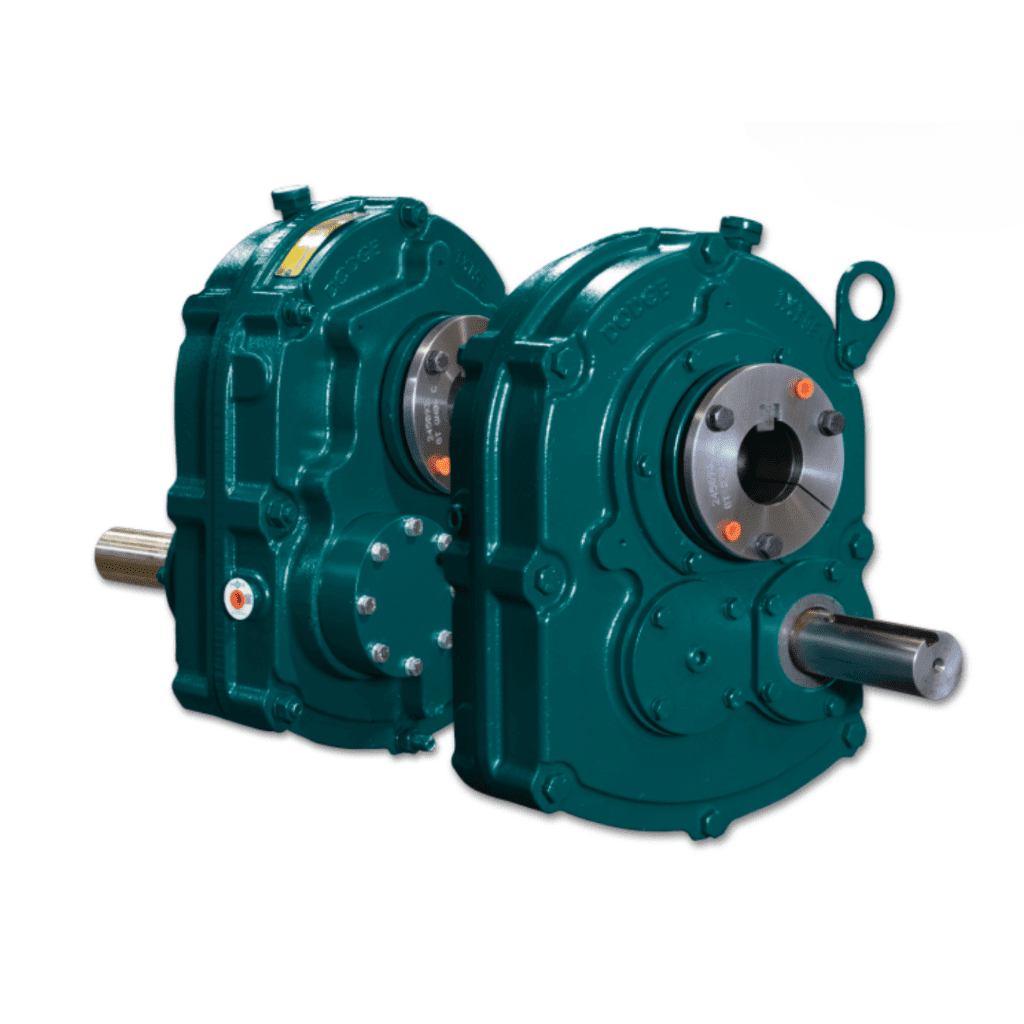

The new, enhanced TXT-E raises the bar and sets an even higher standard for performance and safety with an improved backstop and ready-to-install bushing covers and shaft guards, which include the following features:

Improved Backstop:

- Increased holding power

At least double the holding power than previous generations - Extreme pressure (EP) lubricant compatible

The only shaft-mount reducer backstop designed to operate with EP lubricant to minimize the wear of internal components, extending product life - Lift-off sprag design

Optimized for wear-free operation for long-lasting performance

Bushing Covers:

- Increased safety

Protects workers from rotating equipment - Enhanced protection

Blocks contamination and protects seals to extend product life, saving you money - Ready to install

Pre-drilled and tapped gearcase allows you to attach covers without any modifications

Shaft Guards:

- Designed for safety

Helps eliminate violations and reduces on-site risks, meeting Occupational Safety and Health Administration (OSHA) guidelines - Easy installation

Can be installed with basic hand tools

Length can be easily customized to fit a variety of applications

The Dodge TXT timeline showcases a history of innovation that continues with the new TXT generation. To optimize your industrial operations, consider the benefits that Torque-Arm speed reducers can offer for your specific applications. Explore the Dodge TXT product line for a solution that combines a legacy of innovation with modern safety and performance standards.

Find the Perfect Power Transmission Solution for Your Unique Application

When it comes to power transmission, the needs of each industrial application are as unique as the machinery they drive. Finding the right solution to optimize the performance of your critical production and support systems is crucial. At IBT Industrial Solutions, our team of experts is dedicated to helping you identify the perfect product for your specific application, ensuring that your machinery operates at its absolute best.

If you’re in search of guidance to select the ideal products for your operation, don’t hesitate to get in touch with us today. We’re here to collaborate with you, providing tailored solutions that align precisely with your requirements. Reach out, and let’s work together to elevate the efficiency and reliability of your industrial processes.

Shop Our Online Catalog of Power Transmission Components

Check out ShopIBT.com to find the right power transmission components to meet your needs!