![]()

![]()

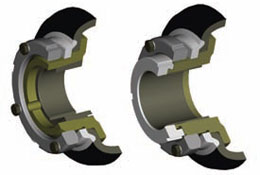

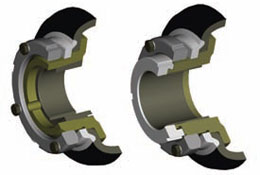

The versatile Para-Flex G-Series is available in three different styles of shaft attachment: Finished Bore (GFB), Taper-Lock® (GTL), and Grip Tight® (GT).

The Finished Bore (GFB) style is a slip-fit, straight-bore solution offering the largest bore size capability of any Para-Flex flange. It requires less shaft length than traditional flanges and features two setscrews at 65 degree angles.

The Grip-Tight (GT) style flange also accepts greater shaft bores via its Grip-Tight bushing with “thin wall” adapters. It offers the largest bushed bore sizes and features a patented keyless bushing system for a full 360 degree concentric grip on the shaft.

Compared to other elastomeric couplings, the new G-Series flange design also offers higher torque capacities to complement the larger bores. This allows users to select a dimensionally smaller, less expensive coupling that has the same capabilities as larger, more expensive offerings.

For more information about Para-Flex G-Series, contact your IBT sales rep or write to us.