Like corded tools, brushed motor tools are slowly becoming less and less sought after in the industrial marketplace. Why? Because when power tools can offer workplace professionals more freedom, power, and control, they can do their job better.

See how brushed vs. brushless power tools compare in terms of design, as well as user advantages and disadvantages.

Differences Between Brushed and Brushless Power Tools

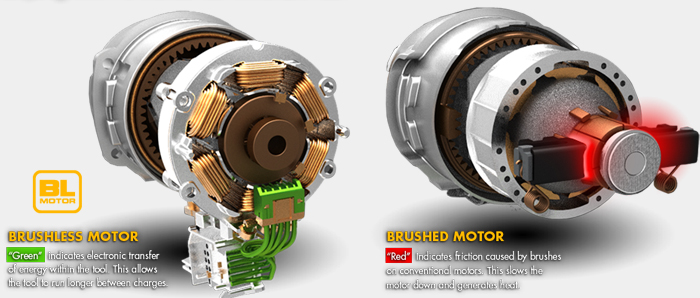

The distinction between brushed and brushless power tools lies in the construction of the motors. In both brushless and brushed electric motors, magnets are responsible for the spinning (rotary) motion of the motor shaft. However, the unique components that generate the electromagnetic field, which keeps the shaft spinning, are ultimately what contributes to the drill’s capabilities.

In brushed motors, the power supply runs through two brushes (little blocks made up of small carbon filaments) on opposite sides of the motor’s shaft. A brushless motor, however, requires an additional set of electrical components (circuit board and sensor) to produce the opposing electromagnetic fields.

Advantages & Disadvantages of Brushed & Brushless Power Tools

There are pros and cons to both brushed and brushless power tools, which are important to understand to ensure you’re using the right one for your application.

1. Friction, Wear, & Tear

As mentioned, the brushes in a brushed power tool are in constant contact with the rotating commutator, which creates friction. In addition to being noisy, this friction creates heat, resulting in energy loss and wear and tear on both the brushes and the commutator.

With brushless power tools, the rotor isn’t in contact with anything, meaning less noise and nothing to wear down over time. In this regard, they’re much more efficient and longer-lasting than brushed tools, anddo not require brush replacements.

2. Power & Efficiency

The elimination of the friction-producing brushes also causes brushless power tools to be significantly more powerful than brushed ones, given the same voltage.

With a brushed motor, you get the same amount of current passing through the motor at any given moment, no matter what task you’re doing. In a brushless motor, because the circuit board delivers current directly to the stationary copper coils, it’s able to adjust the power supply depending on the task you’re doing.

Brushless motors have been tested in comparison to brushed motors with the same capacity battery and typically have 30 to 50 percent more battery life than a brushed motor. This means that a brushless power tool will last longer than a brushed, making it preferred when completely tasks or projects that take more time.

3. Smaller & Lighter

Without the brushes and commutators, brushless power tools are typically lighter and more compact than brushed tools. These lighter tools are easy to carry around for a long day, and being more compact allows them to get into tighter spaces. Less friction and vibration allow brushless power tools to operate more quietly and comfortably for longer periods of time.

4. Less Maintenance

Brushed power tools often require brush replacements every two to seven years because the friction causes the brushes to wear down over time. How often you need to replace the brushes will depend on how often and hard the power tool is used. Because brushless tools generate less heat, they do not need the same air vents for cooling, which means less dirt can get in and require cleaning.

5. Initial vs. Long-Term Costs

The only downfall to brushless motors is cost. The sensors and electric circuitry that’s needed to operate them are complex, and complex things are not cheap. Brushless power tools are typically 30 percent more expensive than brushed ones.

However, brushless tools are worth it. Investing in a newer, brushless tool upfront will get you a more powerful, energy-efficient tool that will outlast its brushed counterpart, ultimately getting you more bang for your buck.

Choose From Brushless, Cordless Power Tools Like The DeWalt FLEXVOLT 9” Cut-off Saw

The DeWalt FLEXVOLT 60V MAX* Cordless Cut-Off Saw is one of the many cordless, brushless power tools we offer that can improve your day-to-day job site tasks. It allows for quick and efficient cuts and scores in concrete, masonry materials,steel, and rebar.

- See the features that set this brushless saw apart.

Want Exclusive Deals On DeWalt Power Tools For Your Next Job Or Project?

Thanks to partnerships with industry-leading names like DeWalt, we offer a wide range of high-quality tools and accessories that are built to last and perform reliably for a myriad of applications.

For exclusive deals on DeWalt FLEXVOLT power tools for your next job or project, contact IBT Director of General Industrial Products, Chris Dowling, today!