Electric motors power critical machinery and equipment in industrial, manufacturing, and commercial facilities. Conveyer belts, pumps, fans, blowers, power tools, and more are all powered by motors that require electric power.

There are two major motor designs: brushed and brushless. Brushed and brushless designs are only for DC-powered motors, or motors that run off a battery. These two motor designs differ in several ways, each offering advantages and disadvantages.

What Is a Brushed Motor?

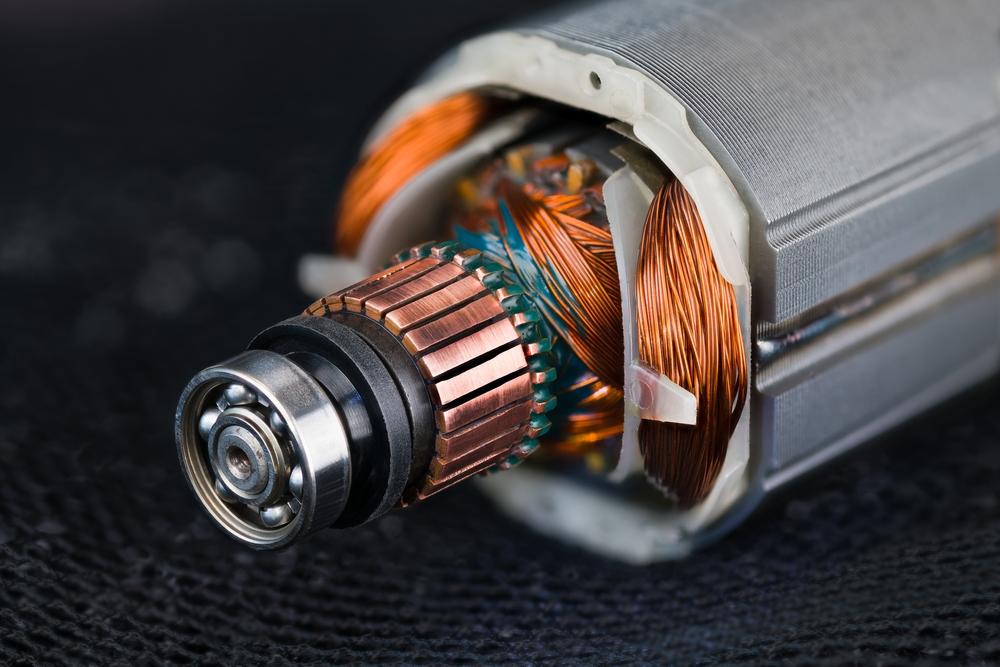

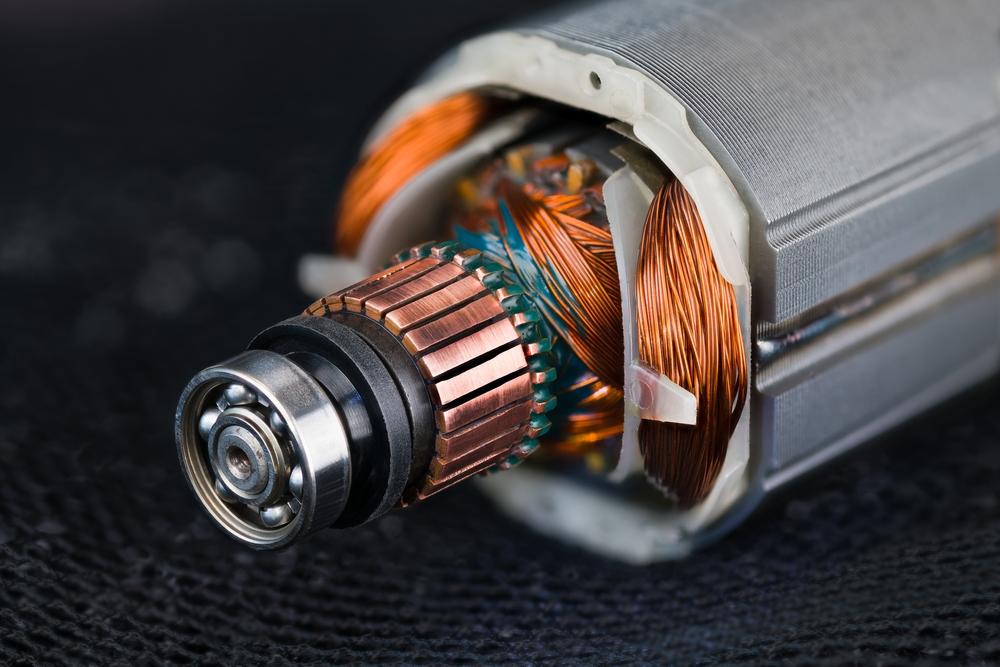

In a brushed motor, the commutator spins around inside a ring of permanent magnets. A magnetic field is created when electricity is applied to the copper coils wound around the rotator, which then react to the permanent magnets surrounding it. These magnetic fields attempt to align (a northern polarity is attracted to a southern polarity). For the commutator to continue spinning, the electromagnetic poles of the rotator must be swapped continually by energizing and de-energizing different sections of the copper wiring.

Changing the polarity is where the carbon brushes come in. These brushes are in charge of the polarity shifts. They contact the commutator’s two (or more) rotating electrodes, which switches the magnetic polarity of the electromagnet as it rotates. Gaps in the commutator plate cause the coils to energize and de-energize in a specific order, switching the polarity and causing rotation.

The brushes are generally made of carbon blocks. These blocks must maintain contact with the commutator to let the electrical currents flow through the coils. The brushes are slowly ground down due to friction because they are pushed into contact with a rotating commutator.

Carbon brushes are used in electric motors due to their excellent electrical conductivity, low friction properties, self-lubrication characteristics, good thermal conductivity, and cost-effectiveness. Carbon brushes are made of natural graphite and fine metal powders such as copper, silver, tin, and lead, with copper being the most prominent.

However, even with self-lubrication, the brushes will eventually need to be replaced. Most brushed motor designs make it easy to replace brushes. Eventually, these brushes will also wear out the commutator they connect to, which is made of soft copper for the best conductivity. Once the commutator is worn completely, the motor will need to be replaced.

What Is a Brushless Motor?

A brushless DC motor, sometimes called a BLDC, is fast becoming the go-to motor design for many applications. It offers superior energy efficiency, lifespan, and operating metrics like acceleration and reduced vibration.

A brushless motor works similarly to a brushed DC motor but has a few key differences. It still has windings (copper wires) that are charged with electric currents to create electromagnetic fields, which push off permanent magnets to create mechanical energy. The difference is that instead of the windings being mounted on the commutator and rotating, the permanent magnets and outer casing are the parts that rotate.

The windings are charged, creating an electromagnetic field that pushes on the permanent magnets. Because there is no interruption in electrical input to the windings (typically three phases, or sets of wire), brushless motors reduce friction, heat generation, electrical arcing, noise, and vibrations.

Brushed vs. Brushless Motors: Pros & Cons

There are advantages and disadvantages to both brushed and brushless motors, though brushless motors have the upper hand in many properties.

This table summarizes the pros and cons of brushed and brushless DC motors, with further explanations below:

| Property | Brushed motor | Brushless motor |

| Maintenance Requirements | Higher | Lower |

| Operating Life | Short (brushes wear out) | Long (no brushes, no friction) |

| Energy Efficiency | Medium | High |

| Speed & Acceleration Rates | Medium | High |

| Torque | Medium | High |

| Weight & Size | Larger | Lighter & More Compact |

| Noise & Vibration Levels | Noisy (electrical arcing) | Quiet & Low |

| Cost | Lowest | Medium (added electronics) |

Maintenance

For brushed motors, because the brushes are constantly rubbing against the commutator, they eventually wear out. If the motor starts stuttering or starts and stops erratically, this can be an indication of worn brushes. Watch out for stuttering and other signs of motor failure. Brushes are usually easy to replace.

Brushless motors will also require maintenance, especially on their bearings, but they don’t require as much maintenance as brushed motors.

Operating Life

Even with maintenance and brush replacement, brushed motors cannot operate as long as brushless motors. It is simply an inherent consequence of the design from the mechanical wear on the brushes and commutator. The brushes slowly wear away the soft copper of the commutator and will eventually reach the end of its service life.

Depending on the type of motor, design, load requirements, and more, brushed motors have an operating life of anywhere from 1,000 to 8,000 operating hours. The operating life of a brushless motor, again varying greater on many factors, can run between 10,000 and 100,000 operating hours.

Energy Efficiency

Brushless motors operate more efficiently than brushed motors. Brushed motors can operate at around 75 to 80 percent efficiency. Brushless motors can achieve 85 to 90 percent efficiency. This is a combination of less friction and energy lost to heat generation.

For perspective, brushless hand power tools last 30 to 50 percent longer on the same battery charge.

Speed & Acceleration Rates

Brushed motors are limited in their rotational speed by the brushes, commutator, and the rotor’s mass. Once high speeds are achieved, the brush and commutator contact becomes erratic, and brush arcing increases. Most rotors in brushed motors have a core of iron, which requires a lot of rotational inertia. This inertia will limit their acceleration and deceleration rates. More powerful rare earth magnets can be used on the rotor to minimize the inertia, but this would increase the cost.

Brushless motors do not have these same limitations to their speed and acceleration rates and provide significantly better performance.

Torque

There is no inherent advantage of brushless motor torque versus brushed motor torque. It comes down to the fact that brushed motors do not have the fine controls of brushless motors and cannot sense when loads on motors increase the torque, requiring more power.

Brushless motors have finer controls built into the system by nature and can sense when higher torque loads are exerted on the motor, thereby adjusting the power accordingly. This allows for much higher torque levels from brushless motors.

Weight & Size

Brushless motors can fit more power into more compact areas than brushed motors. This is most apparent when comparing power tools, but it has many applications, from automobiles to pumps and even electronics. Brushless motors can also weigh less.

Noise & Vibration Levels

Brushed motors can be relatively noisy. As the brushes move over the commutator, they form an electrical switch. These switches are turned on and off repeatedly and quickly, which results in arcing at the contacts.

This arcing can be dangerous in particular environments. The arcing electricity generates a lot of electrical noise and even heat. Capacitors or RC snubbers can mitigate this noise, but there will always be some electrical noise.

As the switches are activated, the current is abruptly moved from one winding to another. The generated torque varies slightly as the windings get turned on and off. A brushless motor can gradually transition the current from one winding to another, but a brushed motor has what is known as a “torque ripple” through the machine. It is a mechanical pulse of energy on the rotor, which causes vibration and mechanical noise, especially at lower speeds.

Brushless motors experience none of these problems and operate quieter and with less vibration.

Cost

One significant advantage brushed motors have over brushless motors is cost. While the steps of manufacturing a brushless motor are more straightforward, the cost of the added electronics is still much higher than the cost of brushed motors. On the other hand, brushed motors have been around for generations and have a mature manufacturing process.

While brushless motors were invented in 1962, they have yet to achieve the same manufacturing finesse as brushed motors. That said, manufacturers are getting better and better at producing electronics. Still, there are limitations; some companies are much further ahead than others. The cost of copper has increased, affecting the costs of both types of DC motors.

Finally, brushless motors are more likely to receive more expensive materials or upgrades, like stronger rare earth magnets.

Applications of Brushless & Brushed Motors

Brushed motors are still widely used in homes, automobiles, power tools, and industrial applications. So, if brushless motors are superior, when should a brushed motor be used?

Brushed motors are used heavily in industrial settings for their ability to change their torque-to-speed ratio, which is only possible with brushed motors. Cost also plays a crucial role in choosing brushed or brushless. The brushed motor can still shine if you need one that will only be used occasionally or for simple tasks.

In the automotive world, most motors are running anytime the car is running. Pumps, fans, and more have all moved to brushless motors for increased efficiency and reliability. Changing to brushless adds to the initial cost, but the lower maintenance and failure rates often make the extra cost worthwhile.

When choosing between a brushed versus brushless motor, it’s important to consider how often each motor will be used for its specific application. If the motor will be used less than the service life of the equipment, it’s best to use the more affordable brushed motor.

Industrial Electric Motors & Supplies at IBT

Whether you need brushed or brushless electric motors, we have everything you need to start and stay running, from the initial motor to the components needed to maintain it. We go beyond just supplying the motor; we help you choose the right motor to do the needed job.

Contact IBT today to learn more, or visit ShopIBT.com to view our selection of DC motors.