Deep groove ball bearings play a crucial role in various industrial applications by quietly facilitating the smooth rotation of machinery. These unassuming components play a pivotal role in ensuring the efficiency and reliability of countless processes. However, they are not without their challenges. In this blog, we’ll explore some of the common issues users encounter with traditional deep groove ball bearings and discover how Schaeffler’s FAG Generation C bearings provide innovative solutions to these challenges.

What are Deep Groove Ball Bearings?

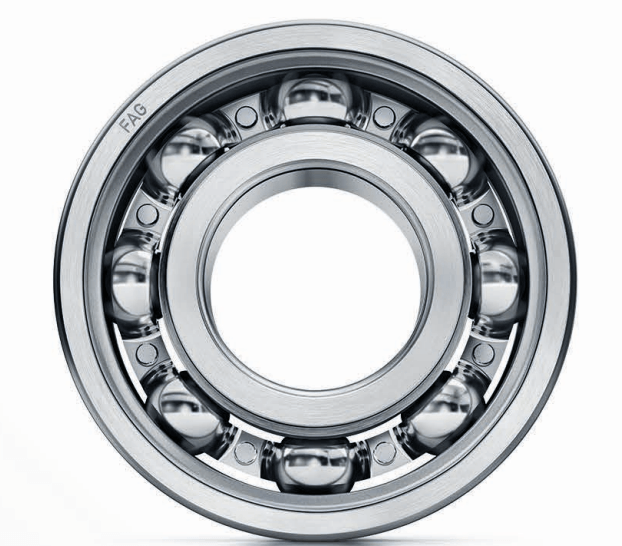

Deep groove ball bearings are a type of rolling-element bearing designed to support both radial and axial loads. They are named for their deep raceway grooves that extend the entire circumference of the inner and outer rings, enabling them to carry loads in a variety of directions.

Deep groove ball bearings are a type of rolling-element bearing designed to support both radial and axial loads. They are named for their deep raceway grooves that extend the entire circumference of the inner and outer rings, enabling them to carry loads in a variety of directions.

These bearings are characterized by several key features:

- Raceways: Deep groove ball bearings have raceway grooves in both the inner and outer rings. This design allows them to handle axial (thrust) and radial (load perpendicular to the shaft) loads simultaneously.

- Versatility: They are highly versatile and suitable for a wide range of applications, from simple household appliances to heavy industrial machinery.

- Longevity: When properly maintained, deep groove ball bearings offer a long operational lifespan, making them a cost-effective choice for various industries.

- Easy Installation: They are relatively simple to install and maintain, which is advantageous for machinery and equipment operators.

- Sealing Options: To protect against contaminants, deep groove ball bearings can be equipped with various sealing options, such as Schaeffler’s patented Z-type shield.

How Deep Groove Ball Bearings Fit Various Industries

Deep groove ball bearings are indispensable components in a variety of industrial and commercial applications, where their reliability and performance are crucial. Some of the most common applications that rely on these bearings include:

- Automotive Industry: Deep groove ball bearings are used in the wheels, transmissions, and engines of vehicles. Their ability to handle both radial and axial loads makes them perfect for automotive applications.

- Agriculture: In agricultural machinery, such as tractors and harvesters, deep groove ball bearings are utilized in the rotating components of the equipment, ensuring reliable performance in challenging environments.

- Industrial Machinery: From conveyor systems to pumps, deep groove ball bearings are a fundamental part of industrial machinery. They keep production lines running smoothly and efficiently.

- Electric Motors: Deep groove ball bearings are a vital component in electric motors, ensuring quiet and efficient operation. Their low noise and friction characteristics make them ideal for this application.

- Mining and Quarrying: In harsh and dusty environments like mines and quarries, deep groove ball bearings are used in a variety of equipment, including conveyors, crushers, and vibrating screens.

Common Challenges That Deep Groove Ball Bearings Face

In the world of machinery and mechanical systems, deep groove ball bearings are integral, providing the fundamental support necessary for the smooth operation of rotating components. Yet, as essential as they are, deep groove ball bearings often face challenges that can significantly impact their performance and lifespan. These challenges include:

- Inadequate Sealing: Traditional deep groove ball bearings sometimes struggle to provide a tight seal against dust and moisture, which can infiltrate the bearing and lead to contamination and premature wear. This is a common issue that can affect various industries where machinery operates in challenging environments.

- Excessive Noise: Unwanted noise during operation is another common challenge, particularly in applications where quiet and efficient machinery operation is critical. Bearings that generate excessive noise can be troublesome, especially in cases like electric motors, where silent performance is paramount.

- Friction and Heat: The friction generated by conventional bearings can result in elevated heat levels. This excess heat can lead to a shorter lifespan for both the bearing and the machinery it serves. Reducing friction and heat is essential for extending bearing and lubrication service life as well as reducing unplanned downtime and damage to machinery.

Discover the Advantages of Schaeffler’s FAG Generation C Deep Groove Ball Bearings

Now, let’s delve into how innovative solutions, such as Schaeffler’s FAG Generation C bearings, address these common challenges and enhance the performance of deep groove ball bearings across a wide range of applications.

Solution 1: Patented Ideas for Better Sealing

- Non-contact BRS Seal: This sealing solution offers optimal protection against dry contaminants while providing excellent grease retention.

- Axial-contact HRS Seal: This advanced sealing technology further enhances protection against dust and moisture.

- The Z-Type Shield: The patented Z-type shield effectively keeps grease in for consistent performance and longevity.

Schaeffler’s sealing technologies in FAG Generation C deep groove ball bearings ensure that grease stays in, and contaminants stay out.

Solution 2: The Quietest in Its Class

Noise can be a significant issue, especially in applications where quiet operation is paramount, such as electric motors. Schaeffler’s FAG Generation C bearings tackle this challenge head-on:

- Design Improvements: The design enhancements in FAG Generation C significantly reduce noise generation during operation, making them one of the quietest in their class.

- Critical Advantage in Electric Motors: Inside electric motors, where noise can be a critical concern, FAG Generation C deep groove ball bearings provide a distinct advantage, ensuring smooth and quiet operation.

Solution 3: Lowest Friction

Excessive friction and heat generation can undermine the efficiency and lifespan of bearings. Schaeffler addresses this challenge through rigorous manufacturing processes:

- Tightening Manufacturing Tolerances: Thanks to Schaeffler’s precise manufacturing processes and ever-tightening tolerances, FAG Generation C deep groove ball bearings generate significantly less friction and, as a result, less heat.

- Best-in-Class Energy Efficiency: Benchmark studies have confirmed that FAG Generation C bearings are best-in-class when it comes to energy efficiency, making them an ideal choice for applications where energy consumption is a concern.

Deep groove ball bearings are essential components in various applications, but they are not without their challenges. Schaeffler’s FAG Generation C deep groove ball bearings rise to the occasion, offering innovative solutions to these common issues. With superior sealing technologies, reduced noise, and enhanced energy efficiency, they ensure peak performance in a wide range of applications.

Find the Right Bearing Solutions for Your Application

If you’re looking to elevate the performance, reliability, and overall efficiency of your machinery and equipment, don’t hesitate to get in touch with our experienced bearing and power transmission experts today. We’re here to provide you with comprehensive information on Schaeffler’s FAG Generation C deep groove ball bearings. Reach out to us to take the first step in optimizing your machinery’s performance.

Shop All of Our Online Bearing & Power Transmission Products

Check out ShopIBT.com to find the bearing and power transmission products for your needs!