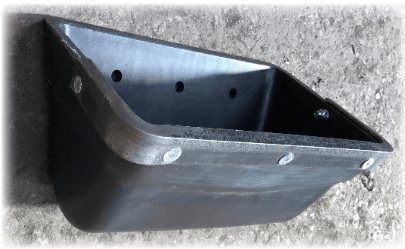

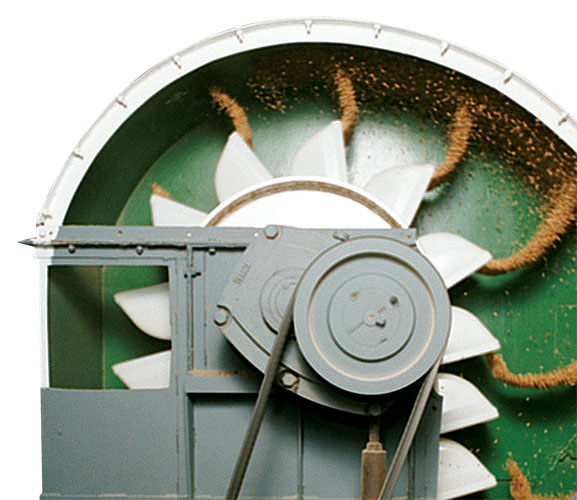

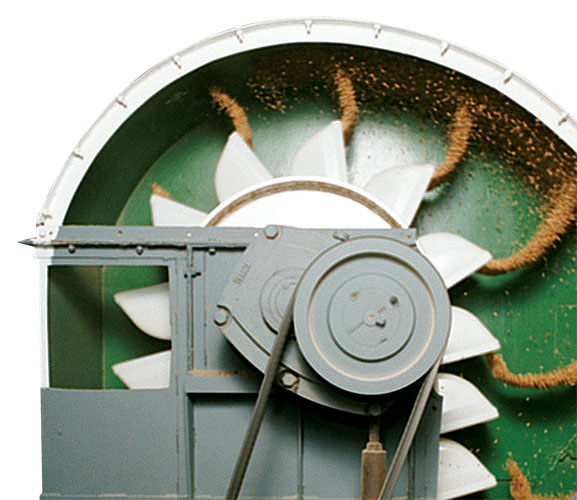

While industrial elevator bucket designs have not changed significantly since the 1950s, the introduction of Nylathane™ by 4B Components brings new emerging technology to the industry for sand, aggregate, and cement applications. Combining Nylon 6 with elastomer, Nylathane™ material provides the ideal solution for elevator buckets in applications where impact tolerance and discharge efficiency of sticky or powdery products are required to minimize downtime and maintain production efficiency.

How Do Nylathane™ Elevator Buckets Compare to Iron and Steel Elevator Buckets?

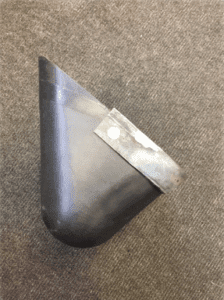

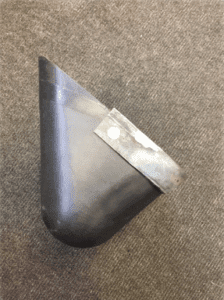

Nylathane™ is a new patented material, which combines the wear resistance of Nylon with the slick release characteristics of polyurethane. Some of the advantages of Nylathane™ include excellent impact strength, self-cleaning properties to keep material from sticking, non-sparking and corrosive-resistant material, and the ability to be easily molded into complex shapes. It’s important to note that prior to its use in elevator buckets, Nylathane™ has been field proven in even more demanding applications, such as track pads for tractors.

Nylathane™ elevator buckets from 4B Components combine durability with weight savings and efficient discharge of sticky materials to help solve common challenges facing the industrial aggregate and cement industries. Iron and steel elevator buckets can be prone to deformation or breakage due to impact from foreign objects or operational issues. Once deformed, their capacity and efficiency are diminished. Deformed elevator buckets pose a risk of further damaging the bucket elevator assembly as they move through the system. Their weight is also a drain on system efficiency due to the amount of energy required to move the heavy bucket assembly.

Upgrade Your Elevator Buckets to Save Money & Enhance Production

The new Nylathane™ line is compatible with most existing elevator buckets employing either belt or chain assemblies. The elevator buckets are easy to install and remove due to their lighter weight material. By replacing iron and steel with a lighter-weight material, Nylathane™ reduces the load on an elevator’s motor, bearings, belt, and other components. Less energy is required to move the bucket assembly.

The new elevator buckets come in several different series and sizes with options for installing metal wear bands used when handling products that have a tendency to stick or lump together. With its self-cleaning nature and release surface properties similar to polyurethane, the new Nylathane™ line does not plug up with sticky or hard-forming products in the way that traditional nylon, steel, or iron buckets do.

Take Advantage of the Benefits of 4B Components’ Nylathane™ Elevator Buckets

The new Nylathane™ bucket lines from 4B Components offer the opportunity to replace traditional steel and ductile iron elevator buckets with a similarly durable but lighter-weight option. Compared to the more traditional materials of metal and ductile iron, Nylathane™ has a number of key advantages, including:

The characteristic advantages of Nylathane™ buckets are:

- Up to 75% lighter than steel or iron

- Outstanding wear resistance

- Superior impact strength

- Self-cleaning surfaces

- Static Dissipative (<108 Ohms)

- Non-sparking & non-corroding

The practical advantages of Nylathane™ buckets are:

- Resists impact and retains original shape while metal buckets deform and lose efficiency

- Reduced weight, thereby reducing overall amp load

- Lighter buckets mean less wear and tear on other components

- Lighter buckets are easier and safer to install and handle

- Lighter weight and better impact absorption mean that Nylathane™ buckets are less likely to pull through the belt or chain than heavier steel buckets

- Compatible with both belt and chain elevators

- Ideal for handling wet or sticky materials

- Static dissipative for use with combustible dust

Let IBT Assist You with Your Next Elevator Bucket Overhaul

IBT partners with trusted suppliers in the industry, like 4B Components, to ensure that our customers can rely on the performance of their applications in even the most demanding environments. With decades of experience in providing conveying systems and components, you can rely on IBT to help find the solutions that will meet your application’s unique needs. Contact our Conveying Systems Division by calling 913-677-3151 or by filling out a contact form today to learn more!

Shop Conveyors & Conveyor Parts Online

Check out ShopIBT.com to find the right conveying parts for your needs!