In the world of industrial equipment and machinery, bearings play a crucial role in supporting rotating components and ensuring smooth operation. The reliability of these bearings is paramount to overall equipment performance and productivity. This blog delves into the significance of preventing bearing failure and how NTN®’s SPAW Series contributes to maximizing equipment reliability.

Understanding Bearing Failure and Its Impact

Bearing failure can stem from various factors such as inadequate lubrication, contamination, misalignment, excessive heat, and overloading. The consequences of bearing failure can be detrimental to equipment performance, resulting in unplanned downtime, reduced productivity, and increased maintenance costs. Frequent bearing replacements and repairs can also take a toll on your overall bottom line.

Best Practices for Preventing Bearing Failure

To maximize equipment reliability and prevent bearing failure, it is essential to follow these best practices:

- Regular inspection and maintenance of bearings: Implement a proactive maintenance schedule to inspect bearings, identify early signs of wear or damage, and perform necessary lubrication and adjustments. Regular inspections can help detect potential issues before they escalate into bearing failures.

- Proper lubrication: Ensure bearings are properly lubricated with the recommended lubricant. Follow manufacturer guidelines for lubrication intervals and use high-quality lubricants suitable for the specific operating conditions of your equipment.

- Correct installation techniques and alignment procedures: Proper installation and alignment are crucial for bearing longevity and performance. Follow the manufacturer’s instructions and utilize precision alignment tools to ensure bearings are correctly installed, aligned, and mounted according to specifications.

- Adequate sealing and protection: Utilize bearing seals and protective measures to shield bearings from contaminants, moisture, and harsh operating conditions. NTN’s SPAW Series, for example, offers superior sealing protection with its spring-loaded, single-lip contact bearing seal and optional end covers for enhanced protection against debris and contamination.

- Optimal load management: Avoid overloading bearings by ensuring proper load distribution across the equipment. Consult load ratings and guidelines provided by bearing manufacturers to determine the suitable load capacities for your application.

Elevate Your Equipment’s Performance with NTN’s SPAW Series

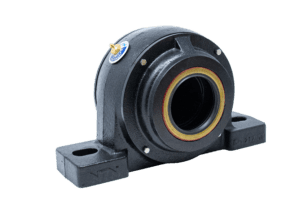

NTN boasts a reputation as a leader in bearing manufacturing, known for its expertise and commitment to innovation. NTN’s SPAW Series takes the spotlight as a heavy-duty, mounted roller bearing solution designed to prevent bearing failure and enhance equipment reliability. Equipped with advanced features, the SPAW Series offers robust performance in demanding industrial applications.

NTN boasts a reputation as a leader in bearing manufacturing, known for its expertise and commitment to innovation. NTN’s SPAW Series takes the spotlight as a heavy-duty, mounted roller bearing solution designed to prevent bearing failure and enhance equipment reliability. Equipped with advanced features, the SPAW Series offers robust performance in demanding industrial applications.

Innovative Solutions for Preventing Bearing Failure

NTN’s SPAW Series offers a range of innovative solutions designed to prevent bearing failure and enhance equipment reliability. Let’s explore these advanced features in detail:

- Heavy-duty, one-piece, sturdy ductile iron housing: The SPAW Series is built with a robust, one-piece ductile iron housing that ensures exceptional durability and can withstand shocks and impacts from falling debris. Additionally, it excels in cold operating conditions, making it suitable for various industrial environments.

- Superior sealing protection with a spring-loaded, single-lip heavy contact bearing seal: The SPAW Series incorporates a spring-loaded, single-lip heavy contact bearing seal that provides superior protection against water and contaminants. This sealing mechanism effectively prevents the ingress of harmful elements, ensuring optimal bearing performance and longevity.

- Extra bearing protection with optional end covers: For applications that require additional protection against severe debris and contamination, the SPAW Series offers optional end covers. These covers, available in configurations of either two open covers or one open and one closed cover, provide an extra layer of shielding for the bearings, safeguarding them from harsh operating conditions.

- Phosphate-coated bearing insert, locknut, and adapter sleeve: To ensure excellent corrosion protection, the bearing insert, locknut, and adapter sleeve of the SPAW Series are phosphate-coated. This coating acts as a barrier against corrosion, extending the service life of the bearings even in challenging environments.

- Pre-lubricated and factory-sealed for quick, trouble-free start-ups: NTN’s SPAW Series comes pre-lubricated and factory-sealed, ready for quick and trouble-free start-ups. This feature eliminates the need for immediate lubrication and setting of internal clearance with feeler gages upon installation, therefore streamlining the setup process and minimizing the risk of improper lubrication that can lead to premature bearing failure.

- Versatile repositionable snap ring for fixed or floating operation: The SPAW Series offers versatility with its repositionable snap ring, allowing for both fixed and floating operation. This flexibility enables the bearings to adapt to different application requirements, ensuring optimal performance and load distribution.

- Drop-in replacement for split housing bearings: The SPAW Series is designed as a drop-in replacement for split housing bearings. With the same base-to-shaft center height and bolt position as SAF/SN units, the SPAW Series facilitates up to 60% faster and easier installation. This compatibility eliminates the need for extensive modifications, reducing downtime during equipment upgrades or replacements.

By incorporating these innovative solutions, NTN’s SPAW Series sets a new standard in preventing bearing failure and enhancing equipment reliability. These features work together to provide robust protection, extend bearing life, and optimize performance in a wide range of industrial applications.

Real-World Case Study Featuring the SPAW Series

Once switching to the SPAW Series of heavy-duty, mounted roller bearing units with open end covers from NTN, the cement manufacturer’s units ran for over 30 months without a single failure, which lasted 10 times longer than the previous bearings. This extended bearing life resulted in annual cost savings of over $161,000, significantly reducing downtime and acquisition costs for the cement manufacturer.

Partner with IBT Industrial Solutions for Superior Bearing Performance

Preventing bearing failure is paramount for maximizing equipment reliability and minimizing downtime. At IBT, we understand the critical role bearings play in industrial equipment and machinery. Whether you need to replace an existing bearing or specify bearings for new applications, our knowledgeable team product experts can help guide you in selecting the right bearings for your specific needs to ensure optimal performance and reliability. Reach out to our dedicated team members today to get your operations rolling smoothly!

Shop All of Our Online Bearing Products

Check out ShopIBT.com to find the right bearing products for your needs!