[CASE STUDY] – When a U.S. industrial motion control manufacturer wasn’t getting the maximum life they desired out of their bearings, they began their search for an integral component to add to their existing lineup of products that would eliminate premature bearing failure.

The primary challenge? Finding a bearing that would meet both the needs AND unique specifications of their operations.

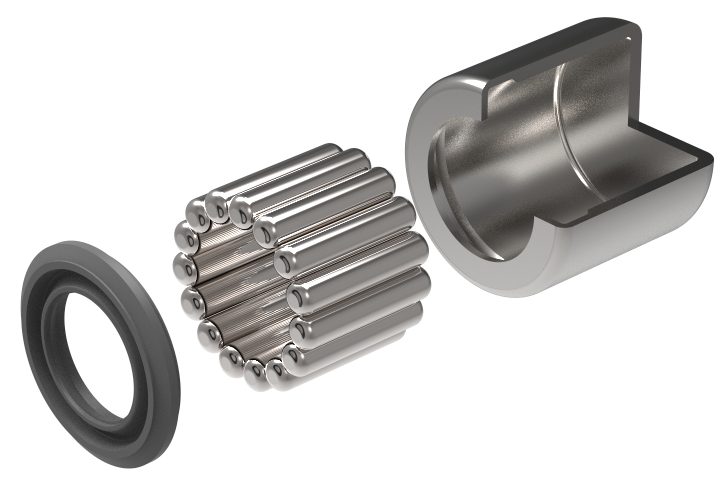

The manufacturer, together with bearing experts from Koyo, determined that high-capacity, closed one end, sealed bearings with a full complement design would be ideal to achieve maximum efficiency within their system. A full complement bearing design, while not common in industrial applications, entails the removal of the retainer in order for additional needles to be fitted, allowing for significant increases in bearing capacity—in either axial or radial directions.

Additionally, a careful bearing analysis found corrosion and poor grease retention to be the primary causes for bearing failure. The new bearing must be able to withstand the harsh operating environment and retain grease well.

The perfect solution required a team of brilliant-minded engineers and a bit of creativity.

The manufacturer turned to the pros at Koyo for assistance in finding the perfect bearing solution, but soon discovered that their standard product offering did not include a bearing with the specific design features and elements they needed.

Working closely with Koyo manufacturing to evaluate all design options, a team of engineers identified a way to combine an existing cup and seal with a new roller and a new assembly process to address all of the customer’s specifications.

The result was better than anticipated.

The new bearing solution exceeded all of the manufacturer’s internal test requirements. Furthermore, the innovative design has also proven to be an efficient solution for other customers around the globe with similar needs.

If you’re unsure why your bearings are failing prematurely, contact your local IBT branch today for expert assistance in finding the perfect solution for your operations!

ABOUT KOYO

Koyo brand ball, needle and roller bearings, manufactured by JTEKT Corporation, boasts two North American Technical Centers located in Plymouth, Michigan and Greenville, South Carolina that are part of a global network of 13 Technical Centers helping to provide solutions for demanding applications through expert analysis and solution development for extending bearing life.