Identifying and correcting machinery problems, such as premature bearing failure, is crucial when it comes to protecting the value of your equipment and avoiding further damage and expense. Misalignment can often be caused by improper installation or loose fits.

Avoid premature bearing failure by learning how to identify and measure bearing misalignment and operating with best practices for mounted bearing installation.

Misalignment & Premature Mounted Bearing Failure

One of the most common causes of motor failure is mounted bearing failure. Mounted bearing failure is often due to improper mounting techniques, especially when it comes to misalignment.

With improper alignment, you run the risk of premature bearing failure, which can cost your operation more in the long run, especially if you must continue replacing mounted bearings before the end of their life expectancy and create unexpected downtime for your operation.

If you are experiencing premature bearing failure, you can determine if it’s due to misalignment by inspecting the wear path. The bearing is most likely misaligned if the wear path isn’t parallel to the raceway edges.

Bearing Installation Considerations for Mounted Bearings

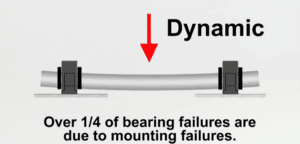

With each bearing installation, a certain degree of bearing misalignment is an expected part of the process; however, the key to proper bearing installation is ensuring that the misalignment falls within the manufacturer’s recommended range. Doing so will help you get the most out of your bearing’s service life. It’s important to note that over 25 percent of bearing failures are due to mounting failures.

There are two types of misalignment: static and dynamic. Below, discover the difference between static and dynamic misalignment, as well as how to measure misalignment during bearing installation, according to Regal Rexnord, one of IBT’s premier bearing suppliers:

Static Misalignment

Static bearing misalignments can occur when:

- The mounting platforms aren’t on the same plane

- A mounting platform isn’t level

- The bearings are offset horizontally

- The bearings aren’t parallel to each other

Dynamic Misalignment

Dynamic bearing misalignment happens during operation and can result from a bent shaft or a heavy load affecting the system.

How to Measure Misalignment During Bearing Installation

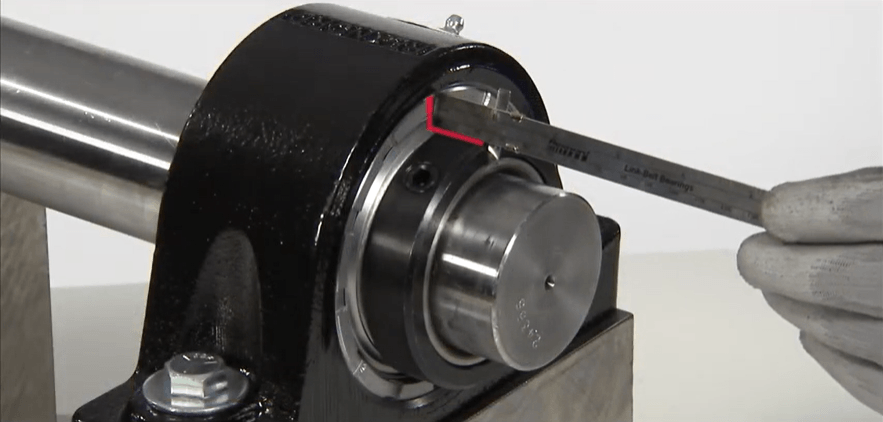

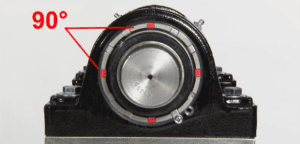

During bearing installation, alignment should be checked and corrected to ensure the bearing operates within its limits.

To measure a bearing’s alignment, measure from the threaded cover to the face of the collar at four points, separated by 90 degrees, to ensure the values are within the manufacturer’s specified limits. If you find that the measurements do not fall within the given value, adjustments will need to be made to the mounting surfaces and/or the bearing itself.

Get the Highest-Quality Mounted Bearings from Regal Rexnord

Regal Rexnord is an industry-leading supplier of high-performance, high-quality bearings, and accessories that are designed to accommodate a wide range of industries and environments.

From mounted and unmounted bearings to specialty bearings and more, Regal Rexnord has the solutions you need to efficiently power your business. In addition to quality products, Regal Rexnord also offers an in-depth library of resources to help with product knowledge, installation, and troubleshooting if you’re looking for additional information for your application.

Contact IBT’s Dedicated IMT Group for Assistance with Proper Bearing Installation

Whether you’re experiencing unexpected downtime and need a bearing replacement quickly or if you’re looking for assistance with troubleshooting, our Industrial Maintenance Technologies Group is here to provide the support you need to optimize the performance of your critical production and support systems.

Our technicians provide expert mounted bearing installation services to ensure your bearings last to specification standards. We will correctly balance your bearings and ensure all your machinery and components are aligned.

In addition to our industrial maintenance services, we can also provide hands-on training to help your facility maintenance team get the experience needed to maintain equipment and manufacturing systems reliably.

Contact our team of industrial experts today or visit ShopIBT.com to purchase bearings directly!

Shop All of Our Bearing Products Online

Check out ShopIBT.com to find the right bearing for your needs!