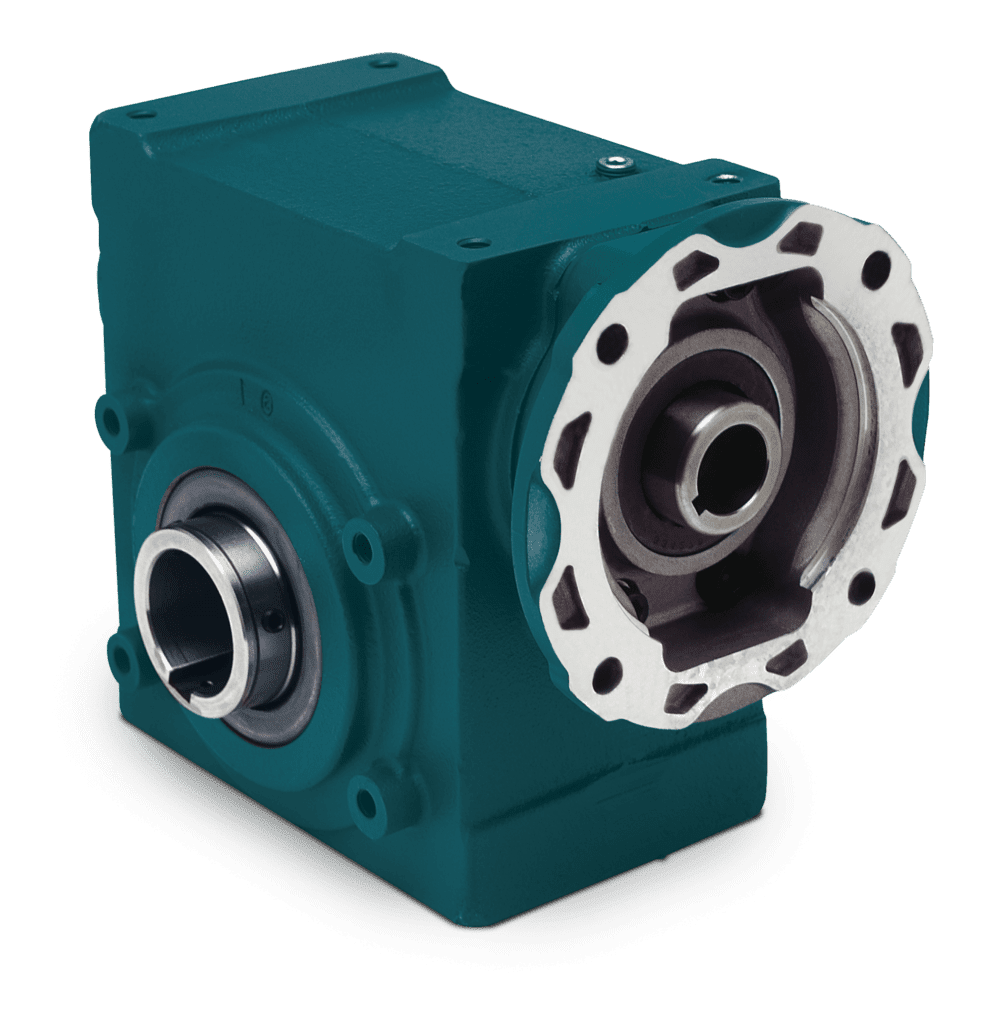

At IBT Industrial, we believe in partnering with the best manufacturers and suppliers to offer our customers uncompromising quality backed by brands they can trust. We also believe in showing versus telling. That’s why, in this article, we’re featuring the rigorous testing that Dodge® Industrial has put its Tigear®-2 worm gearbox through to prove that it is one of the most rugged, long-lasting worm gearboxes in the industry.

Read on to learn more about the parameters of the test and how the components in Tigear-2 compare to the competition.

Putting Worm Gearbox Toughness to the Test

When it comes to assessing a worm gearbox’s strength, there’s more to consider than a catalog’s ratings. According to Dodge, there is a tradeoff between gearbox rating and life when it comes to the design. For instance, ratings may not show the full picture when it comes to loadbearing, horsepower, and safety factors.

To provide a better picture of what makes a Dodge worm gearbox last longer in harsh applications, Dodge conducted side-by-side testing of three brand-new gearboxes from three different manufacturers (including Dodge) in their advanced lab.

For this test, Dodge selected the most common sizes and ratios of worm gearbox: a two-inch center distance with a 15:1 ratio. Each of the units was then tested at an output torque of 1,580 lb-in, which is equivalent to the following ratings for each gearbox: 200 percent for Tigear-2, 197 percent for Competitor B, and 179 percent for Competitor C.

The testing lasted for 500 hours or until gearbox failure, depending on which came first for each of the units. From there, each worm gearbox was disassembled, and their individual components was inspected.

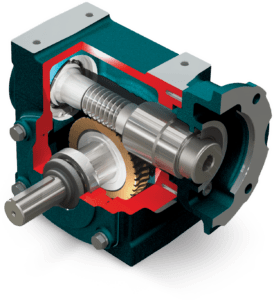

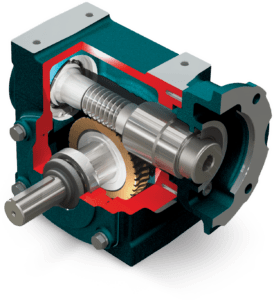

Comparing the Worm Shaft and Worm Gear Components

The two gears in a reduction worm gearbox include a worm shaft and a worm gear. A worm shaft is made of steel, and the stronger it is, the less deflection and stress the component experiences, leading to a longer life.

In comparing Dodge’s Tigear-2 with the worm gearbox units from Competitor B and Competitor C, the post-test evaluation found that the material cross-section of the worm shaft in Competitor B had 30 percent less steel across the length of the worm shaft and smaller teeth, while Competitor C had almost 20 percent less steel across the length of the worm shaft.

When comparing the worm gear across the three worm drive gearboxes, Tigear-2 had the widest of all three with a much larger bore diameter. The worm gear is often the primary wear component within a gearbox, as it transmits the total output torque of the reducer. For this reason, worm gears that feature tougher teeth and wider gear sizes maximize the components’ life.

Evaluating the Shaft Bearings in Each of the Worm Gearboxes

The input shaft bearing is the most critical bearing in a gear reduction box because it runs at motor speed and takes all of the load from the worm shaft. In the evaluation, it was clear that Tigear-2 had a larger input bearing than both Competitors B and C.

Additionally, based on rated dynamic capabilities, when the same load is applied, the input shaft bearing from Competitor B will last only 69 percent as long as Tigear-2, and the input shaft bearing from Competitor C will only last 21 percent as long.

The post-test evaluation found similar results when comparing the output shaft bearings. Both Competitor B and Competitor C use a smaller output shaft bearing and only provide 47 percent as much life as Tigear-2. This is significant, as the output shaft bearings receive the full output radial load, which makes their longevity crucial in high, overhung load applications.

Dodge’s Tigear-2 Worm Gearbox Lasts More Than 500 Hours of Overload Testing

The results of the rigorous test found that the Tigear-2 worm gearboxes ran for 500 hours without virtually any wear detected on the bronze gear teeth. In comparison, Competitor C’s worm gearboxes also ran for 500 hours but noticeable wear step can be observed on all three samples. Competitor B, however, had all three of their worm gearboxes fail in the same way, with an average of 174 hours.

While both Competitors B and C are rated higher than the Tigear-2 gearbox, it still proved to be tougher and outlasted the competition. With Dodge’s legacy of reliability, innovation, and advanced gearbox design, you can maximize durability and minimize wear for your operation, even in some of the most rugged applications.

Find the Perfect Worm Gearbox for Your Application’s Unique Needs

Our gearbox division experts at IBT are here to help you find the perfect solution for your application to help you optimize the performance of your critical production and support systems. If you’re looking for support in selecting the right gearbox, reach out to us.

Contact us today, and our experts will provide the best options for your operation.

Shop All of Our Gearing Components Online

Check out ShopIBT.com to find the right gearing components for your needs!